Compared with metal plungers, the ceramic plunger for pump has many advantages and is an ideal substitute. The ceramic plunger for pump has the properties of corrosion resistance, high temperature resistance and wear resistance. The following Pintejin zirconia ceramic machining manufacturer will tell you about the pump Advantages of using ceramic plungers over metal plungers. Advantages of ceramic plunger for pump Ceramic plunger for pump: 1. More reliable performance Because the production process of ceramic plunger for pump is advanced and the ceramic material itself has very good corrosion resistance, it can be produced by advanced technology.Through the safety performance test of corrosion resistance, acid and alkali resistance, etc. Therefore, Read more

Pintejin Ceramics Factory took you to understand what Aluminum Nitride Ceramic sheets are. I don’t know if you are clear about it. Next, let us understand what are the advantages of aluminum nitride ceramic sheets? Advantages of aluminum nitride ceramic sheets: 1. Aluminum nitride powder has high purity, small particle size and high activity. It is the main raw material for manufacturing high thermal conductivity aluminum nitride ceramic substrates. 2. Aluminum nitride ceramic substrate, high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity, low dielectric loss, is an ideal large-scale integrated circuit heat dissipation substrate and packaging material. 3. The aluminum nitride ceramic Read more

The compressive strength and flexural strength of zirconia ceramics are relatively strong, and their mechanical properties are also strong. Many scientific research laboratories use zirconia ceramics as experimental materials, so what aspects of its mechanical properties are reflected? The following Pintejin Ceramics Factory will give you a brief analysis. Now it can be seen that ceramics are very popular in the international market. It can be clearly seen that industrial ceramics manufacturers have modern management beliefs, advanced ceramic machining technology, and have very strong advantages. 1. Wear resistance: The Al2O3 content in the lining ceramic layer of the ceramic composite steel pipe is more than 90%, and the microhardness is Read more

High-efficiency and high-precision machining method for zirconia ceramic materials 1. ELID superfinishing ELID is the abbreviation of Electrolytic Online Dressing Grinding Method. It applies a grinding wheel composed of metal bond and super-hard micro-diamond (or CBN) abrasive, and at the same time electrolytically sharpens the grinding wheel during the grinding process, so that the grinding wheel is always kept sharp, thus ensuring ultra-precision grinding under high efficiency conditions Therefore, it is an advanced method for mirror grinding of brittle materials (such as ceramics, glass, silicon and iron oxide, etc.). The high material removal rate grinding of zirconia ceramic materials by ELID method can greatly reduce the grinding cost. When reasonable Read more

Zirconia ceramic parts are a new type of material in the machinery manufacturing industry. Zirconia ceramic parts have many good characteristics such as high hardness and strong stability. So what are the inspection methods for zirconia ceramic parts? Next, Pintejin ceramics will introduce to you a bit. Zirconia ceramic parts are aliased as structural ceramics, engineering project porcelain, and ceramics. Compared with traditional parts, they have excellent wear and corrosion resistance properties. The production of zirconia ceramic parts requires the production of powder equipment with high purity, good dispersion characteristics, fine particles and narrow particle size analysis. There are many ways to prepare zirconia ultrafine powder. The purification of zirconia Read more

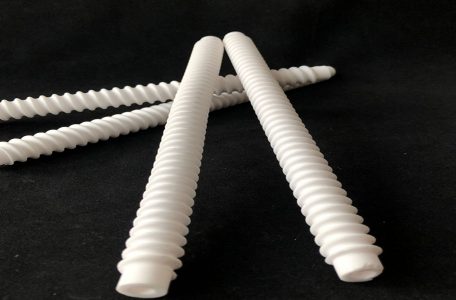

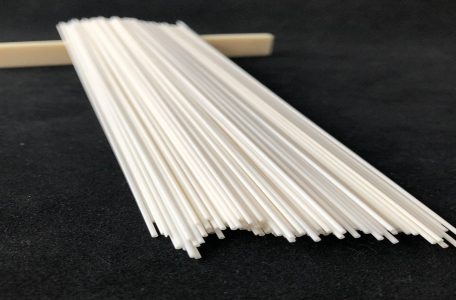

Ceramic rods are generally made of highly wear-resistant zirconia ceramics and alumina ceramics. So what are the specific characteristics of these wear-resistant ceramic rods? The following Pintejin Ceramics Factory will tell you about it. The performance characteristics of wear-resistant ceramic rods are: High hardness: Its Rockwell hardness is HRA80-90, which is only slightly lower than that of diamond, but compared with wear-resistant steel and stainless steel, the hardness is far beyond the two. Good wear resistance: it can prolong the life of the equipment, up to ten times more. Wear-resistant ceramic rods Light weight: The weight is only the average of steel, which can greatly reduce the load on the Read more

Alumina ceramics is the most common ceramic material in many industrial ceramics. It has many characteristics and properties and can be used in all walks of life. The following Pintejin Ceramics Factory will introduce the most significant characteristics of alumina ceramics. 1. Alumina ceramics have good high temperature resistance characteristics, and are a kind of high temperature resistant ceramics with very high mechanical strength and very good conductivity. However, it should be noted that when washing the ceramic, it should be washed with ultrasonic waves, and other items should not be used for cleaning, because it is a very special material. Alumina wear-resistant ceramic plate 2. Very light weight. The Read more

With the continuous development and progress of science and technology, alumina ceramic sheets with superior performance have been widely used in various fields. So what are the advantages and disadvantages of alumina ceramic sheets and how to identify them? Next, Pintejin ceramics will introduce to you. First of all, we will introduce alumina ceramic sheets. Alumina ceramic sheets are also called wear-resistant alumina ceramic linings, high-alumina linings, wear-resistant ceramic linings, alumina ceramic patches. Alumina ceramic sheets are mainly made of AL2O3 as raw materials. It is calcined at a high temperature of 1700 ℃ with rare metal oxides as a solvent. Because of its relatively dense structure and special properties, Read more

Alumina ceramics are the most widely used in the entire ceramic industry, so their performance is also very superior. The use of alumina ceramics in modern society is gradually increasing. Alumina ceramics that can meet various special performance requirements mainly have the following three advantages. 1. High hardness of alumina ceramics The Rockwell hardness of alumina ceramics tested by a third-party professional organization can reach HRA80-90 hardness, second only to diamond. 2. Alumina ceramics have good wear resistance The wear resistance of alumina ceramics exceeds that of manganese steel by more than 266 times and that of high-chromium cast iron by more than 171.5 times. According to the follow-up survey Read more

The preparation of alumina ceramics by casting method was studied, and the effects of powder characteristics and casting parameters on the structure and performance of ceramics were discussed. The impurity content of alumina ceramic raw materials, crystallization tracing, α·phase conversion rate, particle size distribution, etc. have influence on the casting process and the quality of ceramic plates, and the performance index of alumina raw materials for ceramic plates by combined casting method is proposed. It can be seen from the comparison of the heavy ceramic heat dissipation substrate that although the thermal conductivity of the al2o3 material is about 20~51 (w/mk), ltcc adds 30%~50% glass to reduce the sintering temperature. Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump