Ceramic Sintering Ability

What Is Ceramic Sintering

Ceramic sintering is a general term for the densification process and phenomenon of ceramic green bodies at high temperatures. The driving force for sintering is surface energy. Sintering can be divided into two types: sintering with liquid phase participation and pure solid phase sintering. The sintering process is of great significance to the production of ceramics. As the temperature increases, the ceramic body has powder particles with large specific surface and high surface energy, trying to change in the direction of reducing the surface energy, continuous material migration, the grain boundary moving along with it, the pores are gradually eliminated, and shrinkage occurs.

The green body becomes a dense porcelain body with a certain strength.Sintering is a process that reduces pores in the molded body, enhances the bonding between particles, and improves mechanical strength. During the sintering process, with the increase of temperature and the prolongation of heat treatment time, the pores continue to decrease, and the bonding force between particles increases continuously. When a certain temperature and certain heat treatment time are reached, the bonding force between particles shows a maximum value. When the maximum value is exceeded, the pores tend to increase slightly, while the grain size increases and the mechanical strength decreases.

The sintering temperature of zirconia ceramics is 1450°C, and the sintering temperature of alumina ceramics is 1680°C. Their sintering process is to first heat up to about 300°C at the first node, continue to heat up to the highest temperature point, and then keep the temperature for a few hours before starting to cool down. , the material can be taken out of the sintering furnace until it is finally below 100°C. The sintering time of isostatic pressing and dry pressing is about 7 days for the whole process, and the sintering time for injection molding is about 3 days; ceramics have a certain shrinkage rate during the sintering process, and the approximate data is about 1.3. And the shrinkage rate of zirconia ceramics and alumina ceramics is different, so before making each product, we will calculate the size in advance to leave a margin for ceramic machining.

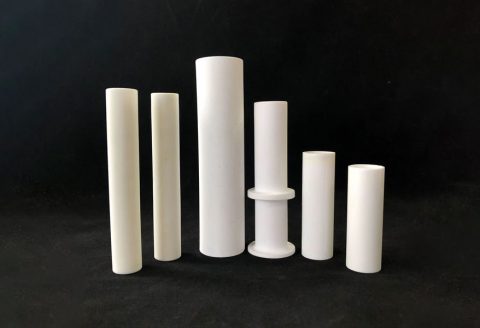

Pintejin ceramic machining shop has a number of high-temperature energy-saving lifting furnaces (electric sintering furnaces), with a monthly sintering capacity of more than 2 million pieces. The factory is still in the process of further expansion. Our customers are better, faster and more ceramic products!