Machinable Ceramic

What Is Machinable Ceramic – Define Of Machinable Ceramic

Machinable ceramic, also known as bioceramic, commonly include macor ceramic, glass-ceramic, etc.

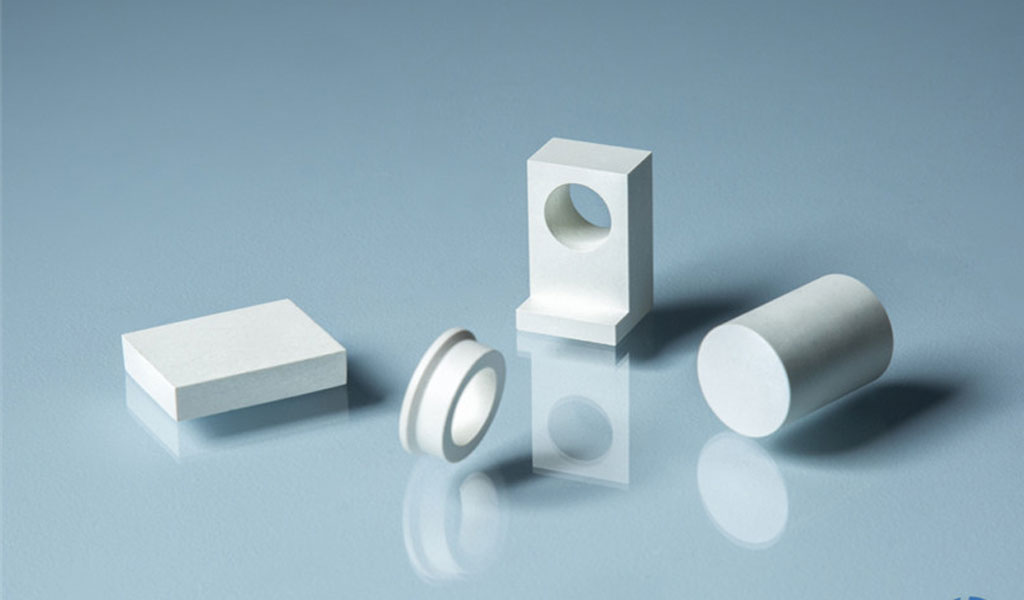

Machinable ceramics are ceramic materials that can be machined with conventional machining methods (such as carbide or high-speed steel tools) at room temperature and maintain certain dimensional tolerances. Usually, the machining accuracy of ceramics and the surface roughness of samples after machining are evaluated. For machinable ceramics, the surface roughness after machining is required to be less than 10 μm. Machinable ceramics can be divided into three categories according to the material composition: mica glass ceramics, non-oxide machinable ceramics and oxide machinable ceramics.

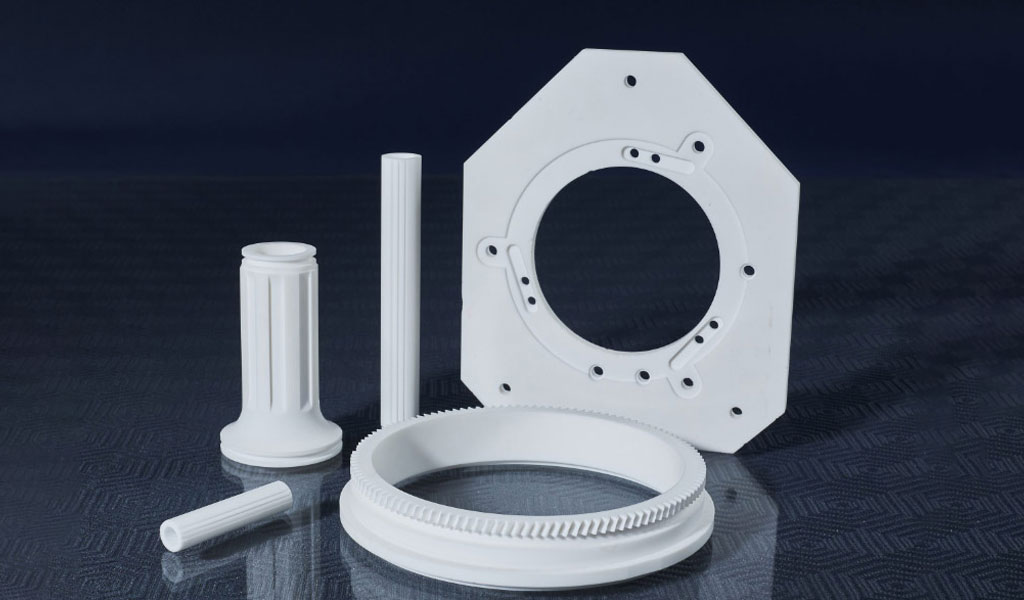

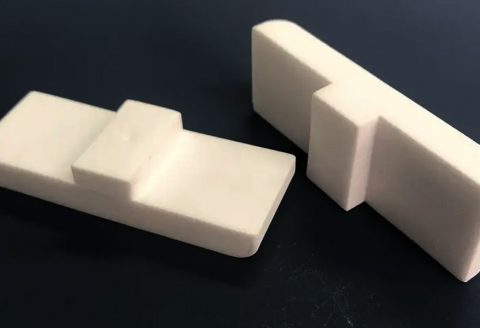

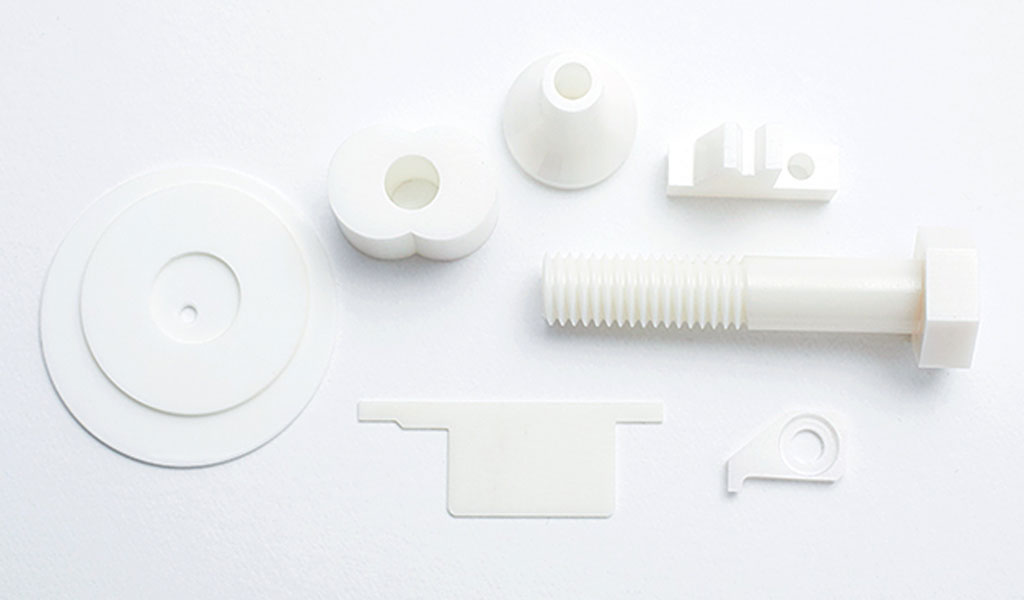

Machinable ceramics can be drilled, turned, milled, tapped, etc., with tools and instruments used for metal processing, and ceramic materials of precise dimensions can be obtained. It has good processing performance, vacuum performance, electrical insulation properties, thermal shock resistance, chemical corrosion resistance and other excellent properties, and different properties play its advantages in different fields.

Custom Machinable Ceramic Parts Services – Machinable Ceramic Products Manufacturer and Supplier

To provide the most demanding CNC services to customers, we engaged precision machining with a diversity of industry ceramic materials. With talented engineers and skilled technicians, CNC machinable ceramic machining services at Pintejin will produce any machinable ceramic structures with high accuracy and efficiency. Using the leading fabrication technologies and software and latest CNC equipment, a wide selection of sizes, quantities, and geometries is available here. We are in the ability to machine or cut machinable ceramic sheet with proper process and ensure the machined machinable ceramic parts meet your custom requirements. Our work is completely based on your digital file to eliminate machining errors. You can upload your CAD file to get a fast and free online quote, we’ll keep track of all the details and get your design to processing in a short time.

Machinable Ceramic Machined Parts

When innovative industries choose to pioneer in the use of new ceramic material, they call Pintejin for a very traditional outcome: a consistently reliable supply of top quality components and cnc machine parts.

Pintejin has a reputation for successfully machining the ceramic other producers prefer not to handle. Customers can confidently design with machinable ceramic materials, secure in the knowledge that Pintejin can machine even the most exotic ceramic for a quality, cost effective result.

The Application Of Machinable Ceramic

Machinable ceramics can be processed into various parts with complex shapes with ordinary metal processing tools and equipment, and can achieve quite high processing accuracy. Therefore, it is processed into various structural ceramics with complex structures, such as insulating pads, thermal insulation pads, insulating supports, and heat-resistant supports on various mechanical equipment.

Machinable ceramics are excellent high-temperature electrical insulating materials, and their electrical breakdown strength per millimeter can reach 40KV/A, which can be used in many electrical equipment such as key parts of lightning rods.

The machinable ceramics are baked at 180°C, kept at 160°C for 1 hour, vacuum aged for 8 hours, and the outgassing rate is extremely low only 8.8×10-9 ml/s. cm2, so it is widely used in vacuum equipment, photovoltaic industry vacuum coating Supports Supports in the vacuum chamber of various vacuum equipment.

Machinable ceramics have excellent corrosion resistance. It is completely composed of inorganic materials, so it does not age and deform, is very stable to various organic solvents, and has good acid and alkali corrosion resistance. It is more resistant to acid and alkali corrosion than ordinary ceramics and PTFE. Compared with PTFE, it is more resistant to corrosion, does not age, and has a long service life. Therefore, it is used in various key parts of the chemical industry such as the introduction rod and hanging of the crude oil desalination electrode.

Machinable ceramic have good electromagnetic properties and can also be used for missile gyroscope coil bobbins.

Machinable ceramics are also used to make rotary vacuum pump vanes. In the absence of metal particles, it has self-lubricating properties like graphite, its specific gravity is 1/3 that of ordinary steel, lighter than aluminum, and its water absorption rate is extremely low.

Therefore, machinable ceramics, because of its various excellent comprehensive properties, can meet high-precision technical requirements, without the need for mold design and production, which greatly shortens the development cycle, can speed up engineering progress, and save development costs, so it is deeply favored by the majority of scientific research, teaching and design departments. Welcome. It is especially suitable for automobile, military industry, aerospace, precision instruments, medical equipment, electric vacuum devices, electron beam exposure machines, textile machinery, sensors, mass spectrometers and energy spectrometers and other instruments.

For some thin-walled coil bobbins, insulating brackets for precision instruments, and devices with complex shapes and high precision requirements, glass-ceramics are more suitable, and they can be processed into any shape. It has higher strength than boron nitride ceramics, low outgassing rate, temperature resistance than PTFE, no deformation, no deterioration, durability, better workability than alumina ceramics, short production cycle, high qualification rate, design Personnel can arbitrarily make products of the required size.

The Advantages Of Machinable Ceramic

Thousands of years ago, early human civilizations used ceramics, and archaeologists have also unearthed many ceramic products of different ages. Today in the 21st century, with the development of modern industry, ceramic materials are more and more used in various fields, and ceramic materials are used in aerospace, machinery, medicine, chemical industry, metallurgy and other fields.

Compared with metal materials and polymer materials, traditional ceramic materials have many advantages such as high temperature resistance, corrosion resistance, oxidation resistance, high strength, etc., and can fully display their excellent properties when used in high temperature, corrosion and other environments. Due to the influence of its own chemical bonds and microstructure, the brittleness and hardness of ceramics make it difficult to process. For example, it is easy to break and crack when subjected to stress, so the use in this area is greatly limited. In order to solve this problem, the research and development of ceramic materials has become one of the current research hotspots. Finally people have developed a kind of ceramics that can be processed by ordinary methods – machinable ceramics.

Machinable ceramics have good processing performance and also have many advantages of ceramic materials, such as high hardness and high temperature resistance. Compared with traditional ceramic materials, the density of machinable ceramics is low, and it is not as high as other ceramic materials in terms of hardness, etc., but the strength of machinable ceramics is one of the best among ceramic materials, and due to its low density, under the same volume, The weight of machinable ceramics is very low, and its density is generally 2.6g/cm3, so machinable ceramic materials have the characteristics of high strength and light weight, which are in line with the mainstream of modern products that are light and strong.

Machinable ceramics can be produced in a variety of colors, because machinable ceramics are manufactured by the accumulation method that can enrich the hue, and the white as the basic color is matched with rich colors. It has strong high temperature resistance and durability. As an inorganic material, it will not deteriorate or fade even in harsh environments.The emergence of machinable ceramics has improved many technical problems, has the advantages of both ceramics and metals, and has a very broad application prospect

The Features Of Machinable Ceramic

Compared with metal materials and polymer materials, traditional ceramic materials have many advantages, such as high temperature resistance, corrosion resistance, oxidation resistance, high strength, etc., and can fully demonstrate their advantages when used in high temperature, corrosion and other environments, but because ceramics The material itself is a hard and brittle material, it is difficult to process it, and there are many disadvantages when used as a structural material, such as easy fracture and cracks when subjected to stress, so the use in this area has been greatly restricted. To solve this problem, people have developed a kind of ceramics that can be processed by ordinary methods – machinable ceramics.

Machinable ceramics not only have good processing performance, but also have many advantages of ceramic materials, such as high hardness and high temperature resistance. In general, the density of machinable ceramic is 2.6g/cm3. Compared with other ceramic materials, the density of machinable ceramics is low, and it is not as high as other ceramic materials in terms of hardness, but the strength of machinable ceramics is that of ceramics.

It is one of the best materials, and because of its low density, the weight of machinable ceramics is very low under the same volume, so machinable ceramic materials have the characteristics of high strength and light weight, which conforms to the mainstream of light and strong modern buildings.

In addition, machinable ceramics can also be made into a variety of colors, because machinable ceramics are manufactured by the accumulation method, which is a method that can enrich the color tone. Color; has excellent weather resistance and durability, and the machinable ceramic itself is an inorganic material, which will not deteriorate or fade even in harsh environments.

The emergence of machinable ceramics has improved the problems of many industries. Because of its advantages of both ceramics and metals, it has a very broad application prospect.