Yttrium oxide is used as a stabilizer, and this material is mainly tetragonal. It has the highest flexural strength of all zirconia materials, especially when sintered and pressed. Yttrium-stabilized zirconia has a fine grain size and is suitable for use in cutting tools due to its high wear resistance for cutting a very sharp corner. The excellent crystal grains make the produced ceramics dense in density, less pores, excellent mechanical strength, corrosion resistance, impact toughness, thermal shock resistance and extremely low thermal conductivity. Due to these characteristics, yttrium-stabilized zirconia is widely used in semiconductor, petrochemical, photovoltaic new energy and other industries.

Yttrium oxide is used as a stabilizer, and this material is mainly tetragonal. It has the highest flexural strength of all zirconia materials, especially when sintered and pressed. Yttrium-stabilized zirconia has a fine grain size and is suitable for use in cutting tools due to its high wear resistance for cutting a very sharp corner. The excellent crystal grains make the produced ceramics dense in density, less pores, excellent mechanical strength, corrosion resistance, impact toughness, thermal shock resistance and extremely low thermal conductivity. Due to these characteristics, yttrium-stabilized zirconia is widely used in semiconductor, petrochemical, photovoltaic new energy and other industries.

Zirconia Ceramic Technical Parameters

| Project | Unit | Zirconium Oxide |

| density | g / cm3 | 5.9~6.05 |

| water absorption | % | o |

| Thermal expansion coefficient | 10-6/k | 10.5 |

| Young’s modulus of elasticity | Gpa | 210 |

| Poisson’s ratio | / | 0.3 |

| Rockwell hardness (HV) | HRA | 88~90 |

| Webster hardness | Gpa | 12 |

| Flexural strength (room temperature) | MPa | 950 |

| Bending Strength (700°℃) | MPa | 210 |

| Compressive strength (room temperature) | MPa | 2000 |

| fracture toughness | Mpa.m1/2 | 10 |

| Thermal conductivity (room temperature) | W/m.k | 2~3 |

| Specific resistivity (room temperature) | Q.mm2lm | >1015 |

| Maximum use temperature | ℃ | 1350 |

| Acid and alkali corrosion resistance | l | powerful |

Yttrium-stabilized zirconia can be used to make crucibles for vacuum induction melting, high-purity zirconium sizing nozzles or zirconium composite long nozzle bricks for steelmaking, etc., and to make furnace linings and gas reaction furnace linings with high temperatures above 1800 °C brick. Because of its semiconductor properties, zirconia products can be made into high temperature electric furnace heating elements, high temperature furnace tubes, wire drawing dies, etc. It can also be made into zirconia ceramic components for continuous temperature measurement of high temperature solutions and zirconia components for various oxygen determination instruments. Fused zirconia sand can be used as aggregate for zirconium unshaped materials, foundry sand for titanium alloys and plasma spraying materials. With the development of science and technology, the use of stabilized zirconia is constantly expanding to different fields.

Main Features of Yttrium Stabilized Zirconia

- Good mechanical strength

- Excellent wear resistance

- High impact resistance

- Very low conductivity

Main applications of yttrium stabilized zirconia

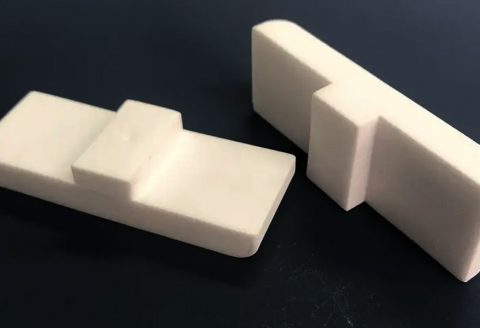

- Structural Ceramics

- Wear parts

- Thermal barrier coating

- Dental ceramics

- Optical fiber

- Ferrules and Bushings

- Grinding media

- Oxygen Sensor