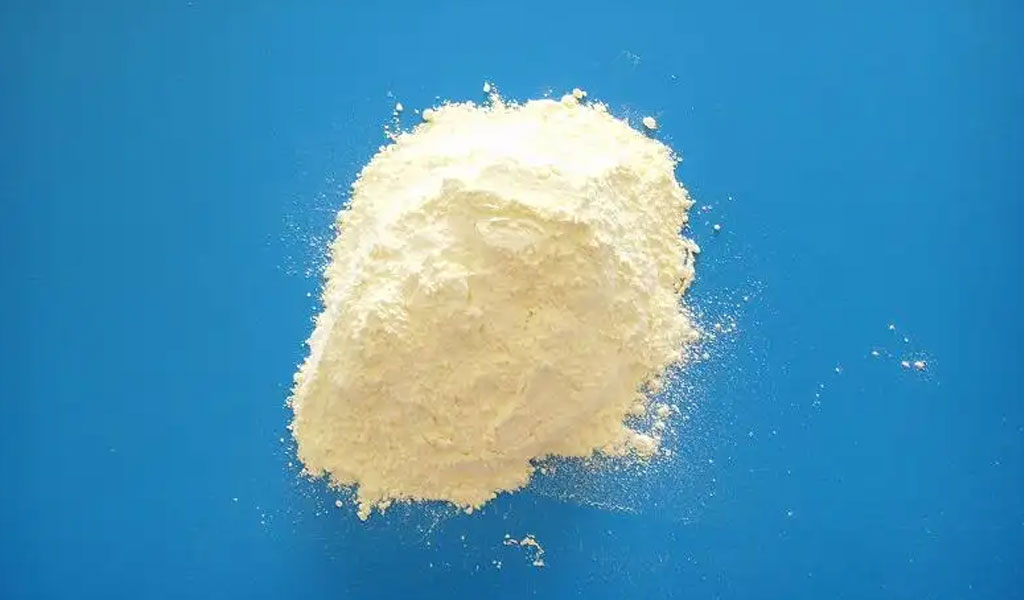

It is made by the process of cerium oxide stabilization, titration molding, and calcination for phasing. Cerium oxide is used as a stabilizer, which produces high-density zirconia ceramics with a density of 6.2 g/cm3. Due to the material’s good abrasion resistance and high density, it is mainly used for the production of grinding media, especially for grinding highly viscous compounds and paints. The high density also allows for the production of smaller grinding media, greatly increasing grinding efficiency and reducing grinding time. Cerium-stabilized zirconia is similar in wear resistance, fracture toughness and mechanical strength to yttrium-stabilized zirconia material. The microstructure is more delicate and the density is higher, which is suitable for the dispersion and grinding of high solid content and difficult to decompose materials!

| Project | Persimmon stabilized cobalt oxide |

| Chemical Composition | zrO2 ≥80% |

| True Density | 6.2g/cm3 |

| Bulk Density | 4.0g/cm3 |

| Crushing Strength | ≥2.0KN(2mm) |

| Moh’s Hardness |

Cerium Stabilized Zirconia Main Applications

- Grinding medium

- Structural Ceramics

- Automotive catalytic system

Main Features of Cerium Stabilized Zirconia

- High density

- Excellent wear resistance

- High impact resistance

- Good fracture toughness