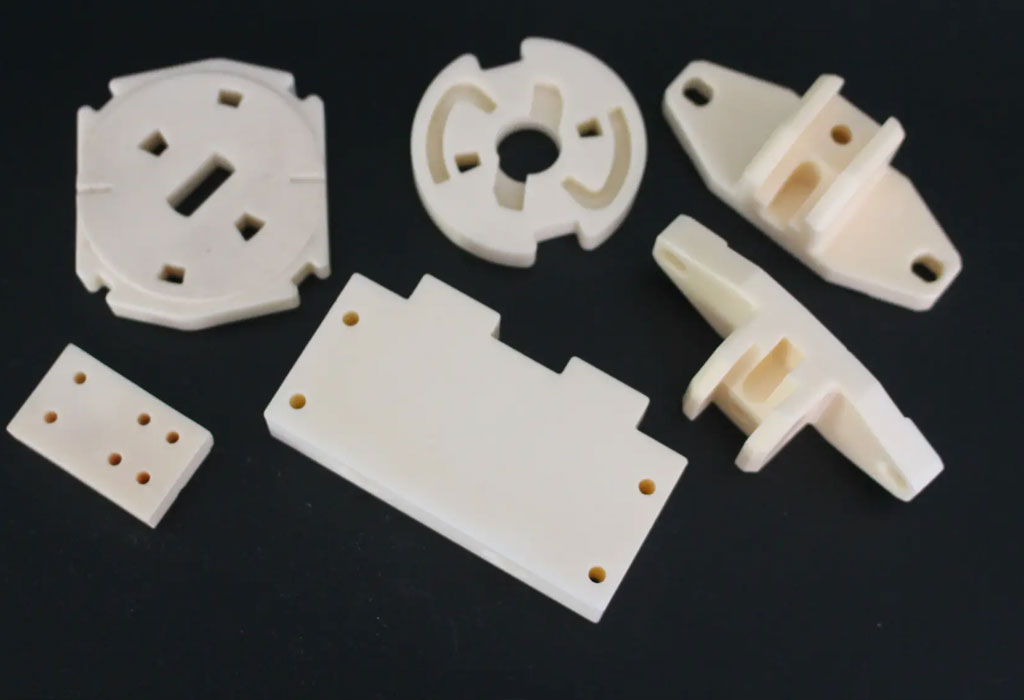

CERAMIC MACHINE SHOP

Founded in June 2007, Pintejin Ceramic Industrial Technology Co., Ltd. is a professional enterprise engaged in R&D, manufacturing and sales of non-standard industrial ceramics, hard alloys (tungsten steel) and various metal and non-metal precision machinery parts.

The company adheres to the business philosophy of “being honest, doing things with care.” Adhere to the market-oriented, technology-centric, people-oriented, customer satisfaction as the business pur- pose, The company has strong technical level in the field of industrial ceramics (zirconia, alumina, silicon ni- tride, silicon carbide, aluminum nitride, microporous ceramics, etc.) and hard alloy (tungsten steel) non-standard precision parts and components. A number of process technologies are leading the indus- try.

The Pintejin ceramic machining shop has a group of professional technicians who have been engaged in the industry for more than ten years and has strong technical research ability. It has a complete production process and quality management system, as well as a complete set of precision processing equipment and inspec- tion equipment.The company strictly implements ISO9001 international quality system certification and ISO14001 environmental certification system, and can customize products of various specifications according to customer requirements, drawings and samples, welcome guests and friends to visit our company, communicate and cooperate, we will cooperate with new and old customers Common development and create a bright future.If you are willing to work with us or want to know more details, welcome to contact us via email.

HOW WE WORK

The company’s main products are: zirconia ceramic precision parts, alumina ceramic precision parts, silicon nitride ceramic precision parts, silicon carbide ceramic precision parts, hard alloy (tungsten steel) precision parts. Products are widely used in: precision machinery manufacturing, microelectronics, semiconductor, aerospace, aviation, bio- medical, fiber optic communications, optoelectronics, testing, inspection, photovoltaic solar energy and other professional fields.

- Radial size can reach 0.0015mm, roundness

- 0.001mm, concentricity 0.0025mm,

- roughness 0.02;

Hole Parts:

- Machined minimum hole diameter of 0.2mm,

- depth can be 3mm, hole above 1mm, radial dimen-

- sion tolerance 0.002mm, roughness 0.02-0.04;

As a professional ceramic company, Pintejin can meet the following ceramic plane machining standards:

- Tolerance can be achieved 0.002mm, flatness

- 0.0015mm;

- The stage difference accuracy can reach 0.002mm,

- and the R angle clear root can achieve R0.02mm;

- It can process internal thread of M2 or above,

- thread precision GB- 7H; external thread size is not

- limited, thread precision GB-6g;

KEEP IMPROVING CRAFTSMANSHIP AND APPLICATION SCOPE

We are a group of technical practitioners who. share common ideals, like-minded, and determined to specialize in precision manufacturing. Our goal is: Strive to be a first-class precision machinery manufactur- ing enterprise!

PROVIDE MATURE CERAMIC MACHINING SOLUTIONS

High Precision CNC Machine

- The Number Of Machining Center: 70 Ceramic CNC Machines;

- Machining Accuracy: ±0.01mm;

- Cnc Machining Objects: silicon nitride ceramics, aluminum nitride ceramics, zirconia ceramics, machinable ceramics, bioceramics, silicon carbide ceramics, etc. ;

- Machining Form: contract labor

Precision Grinder Workshop

- Equipment Name: High Precision Surface Grinder

- The Number Of Devices: 16

- Grinder Brand: China DALIAN

- Machinable Materials: zirconia ceramics, alumina ceramics, silicon carbide ceramics, silicon nitride ceramics, aluminum nitride ceramics, etc.

- Grinder Machining Accuracy: ±0.001mm

Ceramic Sintering Furnace

- Our company is equipped with sintering furnaces of well-known brands, which can sinter shaped ceramic bodies such as zirconia and alumina, and can provide more complete full-process ceramic cnc machining services.

- Number of Machine Tools: 3

- Production capacity: silicon nitride ceramics, aluminum nitride ceramics, oxide

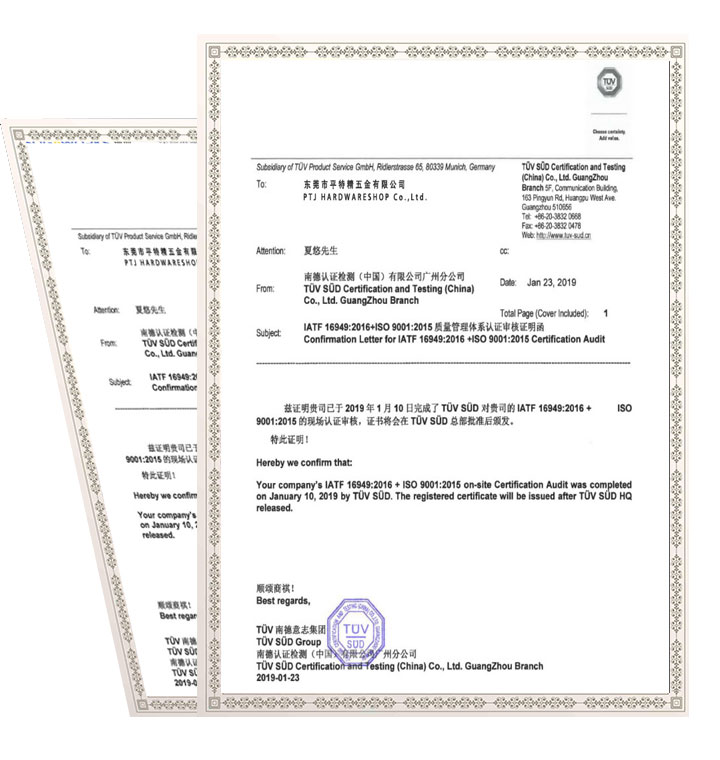

INDUSTRIAL EQUIPMENT TESTING AND CERTIFICATION

- Comprehensive written procedures and policies

- Extensive electronic records of orders, customer communications and inspection results

- Detailed records of incoming raw materials

- Analysis of root cause of non-conformances

- Corrective actions to prevent recurrence of non-conformances

- Multi-level incoming order review

- Comprehensive software expert system advising customers of manufacturability issues

- Periodic calibration and labeling of inspection tools

- Designated areas for non-conforming parts

- Daily backup of electronic records stored in multiple locations

As a full-service ceramic machining company, we support you from the pattern design to finished ceramic product and parts through cnc machining, mold making, punching, engineering design and ceramic sintering as well as surface treatment for the Zirconia Ceramics,Silicon Nitride Ceramic, Alumina Ceramic , Silicon Nitride, Machinable Ceramics, Bioceramics, Aluminum Based Silicon Carbide,Silicon Carbide Ceramics,Boron Carbide Ceramics

and More Ceramics.

Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your ceramic machining project.