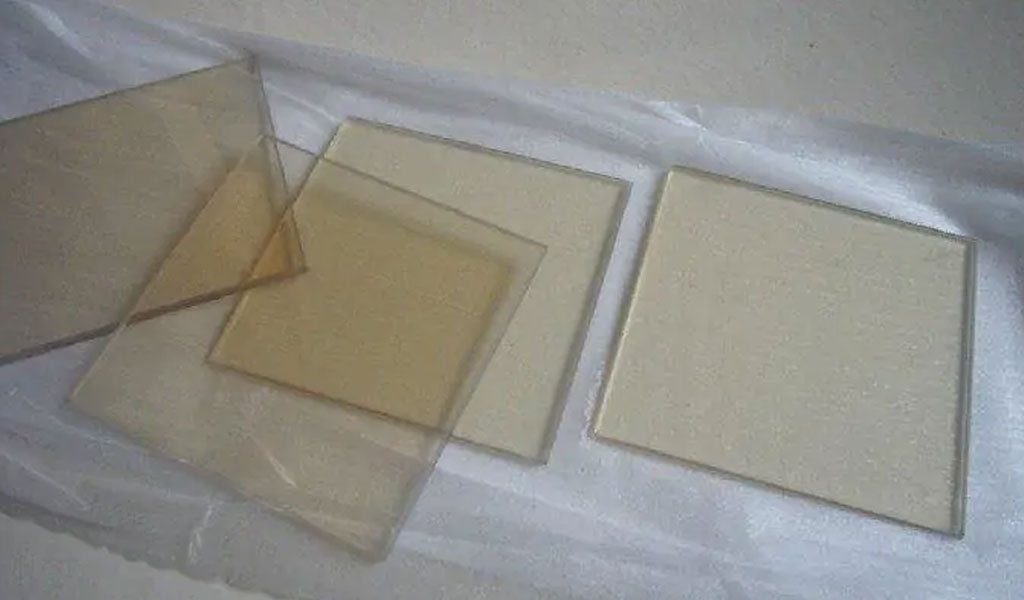

Glass Ceramic

What Is Glass-Ceramic

Glass-ceramics, also known as machinable ceramic, are mica glass-ceramic with synthetic mica as the main crystal phase, and are machinable ceramic materials.

The most prominent feature of machinable glass-ceramics is that standard metal processing tools and equipment can be used for turning, milling, planing, grinding, sawing, cutting and tapping, which is incomparable to general 95 porcelain, silicon nitride porcelain and other insulating materials. of. The processing performance of glass-ceramic ceramics is similar to that of cast iron, and it can be processed into various products with complex shapes and high precision requirements.

Although glass-ceramic is a brittle and hard material, as long as the processing route and clamping method are reasonably determined, the processing method is paid attention to, and the cutting amount is selected accurately. In general equipment, the tolerance level can be controlled at IT7 level, and the smoothness can reach 0.5 microns. The machining accuracy is controlled at 0.005 mm. If the machining equipment is excellent and the operator is skilled, the precision can reach μ level.

The Feature Of Glass-Ceramic

Glass-ceramic has good processing performance, vacuum performance, electrical insulation properties, high temperature resistance, chemical corrosion resistance and other excellent properties. Glass-ceramics glass-ceramics with high mechanical strength, machinable glass-ceramics and bioactive glass-ceramics

- High strength and light weight: glass-ceramic is harder than natural stone and is not easy to be damaged. The thickness of the material can be matched with the construction method, which is in line with the mainstream of light and strong modern buildings.

- Rich and changeable colors: The glass-ceramic is manufactured by the accumulation method, without the natural stone texture (breaks from here), the accumulation method is a method that can produce rich tones, with white as the basic color. Rich color system, and the three color systems of white, rice and gray are the most frequently used.

- Excellent weather resistance and durability:The acid resistance and alkali resistance of glass-ceramic is better than that of granite and marble, and it is an inorganic material. Even if it is exposed to wind, rain and polluted air, it will not produce deterioration, fading, and poor strength.

- Electrical properties Glass-ceramic is an excellent high-temperature electrical insulating material, which can be used in many electrical equipment, and has high electrical insulating strength.

- Since it is completely composed of inorganic materials, it also has no aging and no deformation, very stable to various organic solvents and good acid and alkali corrosion resistance.

The Application Of Glass-Ceramic

Glass-ceramics are especially suitable for automobiles, military industry, aerospace, precision instruments, medical equipment, electric vacuum devices, electron beam exposure machines, textile machinery, sensors, mass spectrometers and energy spectrometers. For some thin-walled coil bobbins, insulating brackets for precision instruments, and devices with complex shapes and high precision requirements, glass-ceramics are more suitable, and they can be processed into any shape.

Glass-ceramic is a new type of building material just developed in my country. It has the good characteristics of glass-ceramics, so it will be more and more widely used.

The Technical Data Of Glass-Ceramic

- Density ρ: 2.6g/cm3

- Thermal linear expansion coefficient a (20-800℃) (0±0.5)*10-6K-1

- Heat capacity: cp (20-100℃)0.8KJ*(KQ*K)-1

- Thermal conductivity: A (90℃) 1.6W*(m*k)-1