There are many methods for forming alumina ceramics, such as dry pressing, grouting, extrusion, cold isostatic pressing, injection, casting, hot pressing and hot isostatic pressing. So what are the treatments that need to be done after forming alumina ceramics What? Next, Pintejin Ceramics will introduce to you. 1. Dry grinding In the process of preparing alumina ceramics, it is necessary to use sandpaper to polish the alumina ceramics. Usually, this bile film is more suitable for the hard and brittle paint.A certain amount of dust will be generated during the grinding process, so the preparation staff of Dongguan alumina ceramics should pay attention to avoid inhalation. 2. Wet Read more

What is the basic principle of the way to semiconductorize functional ceramics? What are the factors that affect semiconductorization? The way to semiconductor: 1. Donor doping semiconducting, generally high-valent doping La3+, Y3+, Sb3+, Nb5+, Ta5+Fundamental: 2. Forced reduction semiconductorization. Basic principle: Factors affecting semiconductorization: (1) Influence of additives and impurities. If the concentration is too large or too small, the resistivity will increase and an insulator will be formed. (2) The influence of deviation of stoichiometric ratio. 3. The influence of firing conditions. The influence of firing temperature and holding time is greater.

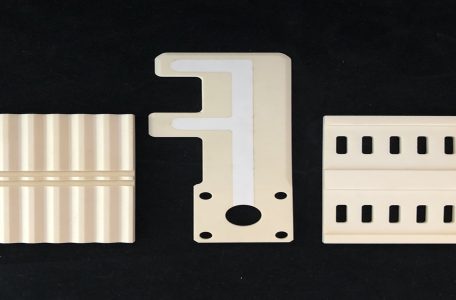

There are many ways to process structural ceramics. According to different machining requirements, the following are the common methods of structural ceramics machining by Pintejin zirconia ceramic machining manufacturers. Structural ceramic machining surface grinding There are many methods for structural ceramic machining surface machining, basically all machining methods can process plane, turning, milling, planing, grinding, drawing, wire cutting. Among them, it is most used in surface grinders. Grinding is generally used for finishing. Planing and wire cutting are generally used when batches are very small. The surface roughness of structural ceramics is that after the ceramic parts are formed and sintered, there will be many uneven peaks and valleys on Read more

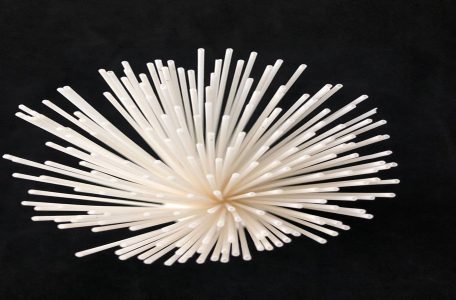

Ceramic rods usually use wear-resistant zirconia ceramics or alumina ceramics as raw materials, which have excellent performance, but some factors will affect the use of ceramic rods. Pintejin Ceramics Factory will tell you what factors will affect ceramic rods? Influence of raw material powder: The main raw material of ceramic rod is high-purity zirconia powder, and its performance and content have a great influence on zirconia ceramics. In the preparation process of ceramic powder, it is inevitable to introduce impurities. The organic impurities are burned off during the firing process, and irregular pores are formed in the process of early densification. Inorganic impurities may react with the ceramic powder at Read more

The basic requirements for insulating ceramics are small dielectric constant, low dielectric loss, high insulation resistivity, high electrical strength, high mechanical strength, good thermal shock resistance, stability of humidity and frequency, etc., then the role of insulating ceramics And what are the characteristics? Next, Pintejin Ceramics will introduce to you. Insulating ceramics can be used to manufacture insulating parts of ultra-high frequency and high-power electric vacuum devices, as well as ceramic shells of vacuum condensers, ceramic components of microwave tube transport windows and various ceramic substrates. Soap porcelain uses natural mineral talc as the main raw material, and then stubbornly becomes the most important crystal phase of ceramics, Read more

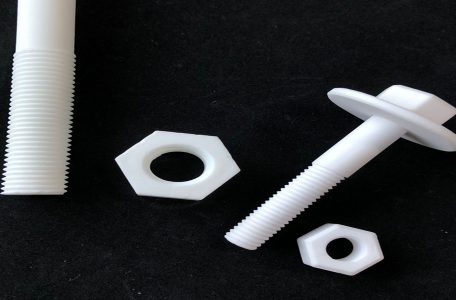

Alumina ceramics have high hardness, high strength, insulation, wear resistance and corrosion resistance. They are widely used in machinery manufacturing, aerospace, petrochemical and other fields. Next, Pintejin Ceramics will introduce the characteristics of alumina ceramic injection molding. . Features of Alumina Ceramic Injection Molding 1. The alumina ceramic molding body has high strength and can be machined into parts with complex shapes. Due to the action of organic polymers, the strength of the body is 20-40MPan. The parts with this strength can be processed in various ways.As a result, parts with more complex shapes, more accurate dimensions and smoother surfaces can be processed, so the process reduces the production Read more

The molding process of zirconia ceramics has always been a very important step, so the requirements for the slurry are also very strict, which will determine the performance of the ceramic after machining. The following are the main requirements of Pintejin Ceramics for the slurry. Zirconia ceramic forming refers to adding an appropriate amount of water or organic liquid and a small amount of electrolyte to the powder to form a relatively stable suspension, and injecting the suspension into a plaster mold to absorb water to achieve the purpose of forming. The key to forming zirconia ceramic slurry is to obtain a good slurry, and its main requirements are: ①Good Read more

Grouting is actually the earliest molding method used for alumina ceramics. Because it mainly uses gypsum molds, it will be cheaper in cost and easier to shape. Even if the size and shape are more complex, it is easier to shape, but The most critical thing for grouting is the production equipment of alumina slurry. Normally, water is used as the main medium of the solvent, and then the binder and debonding agent will be added. After sufficient grinding, the air is exhausted. Pour it into a plaster mold. The capillary of the gypsum mold will absorb the water, and the slurry will be solidified in the gypsum mold relatively Read more

In the production process of zirconia ceramics, energy is mainly consumed in the links of spray drying and pulverizing, semi-finished product drying and roller kiln firing. Therefore, improving the energy utilization efficiency of these three links is the main way to save energy in industrial ceramics manufacturers. Among them, the energy saving in the firing process of the roller kiln is the most critical. Pintejin Ceramic Factory will give a brief introduction to its energy-saving technology. (1) Select raw materials Raw materials are an important basis for industrial ceramic production. For large-scale industrial production, the performance of raw materials is required to meet production needs, with stable quality and Read more

Zirconia ceramics is a special ceramic material emerging in recent years. It has phase transformation toughening and micro-crack toughening, so it has high strength and toughness, and is known as “ceramic steel”. Zirconia has the highest fracture toughness of all industrial ceramics. Using the excellent room temperature mechanical properties of zirconia ceramics to optimize the zirconia formulation and process, a fine-grained zirconia ceramic with high hardness, high strength and high toughness is obtained. High hardness, high strength and high toughness ensure that zirconia ceramics have incomparable wear resistance compared with other traditional structural ceramics. Fine-grained zirconia ceramics can be processed to obtain very low surface roughness (<0.1um). Therefore, the friction Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

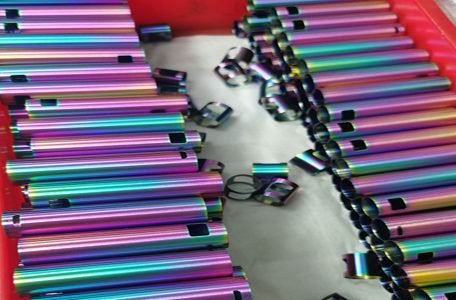

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump