Since zirconia ceramics have relatively unique properties, and they have been valued in the market, the most important thing is to attract the development and research of researchers, so how can zirconia ceramics be polished into a mirror surface? Next, Pintejin ceramics will introduce to you a bit. The basic method of ceramic material machining: ceramic materials usually need to go through blank cutting, grinding, grinding and polishing and other processes to make the required parts. Product categories: ceramic plungers, ceramic pump cores, ceramic valve cores, ceramic pistons, ceramic bushings, ceramic suction cups, microporous ceramics, etc.; materials: alumina, zirconia, silicon nitride, silicon carbide. Grinding and polishing is a super-finishing method Read more

Blog

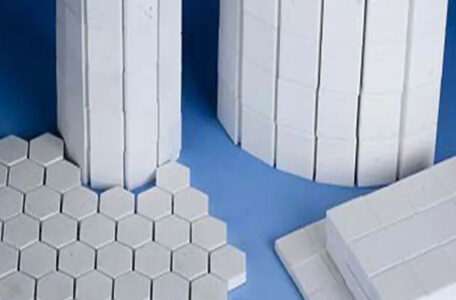

95 alumina ceramic is a widely used ceramic in structural ceramics, because it has excellent electrical properties at high frequencies, low dielectric loss, high volume resistivity, high strength, high hardness, and low linear expansion coefficient. So what is the process of hot pressing of 95 alumina ceramics? Next, Pintejin Ceramics will introduce to you. The molding methods of 95 alumina ceramics include dry pressing, hot die casting, pouring, extrusion, etc. In recent years, pressure filtration molding, direct solidification injection molding, gel injection molding, centrifugal grouting and solid free molding have been developed at home and abroad in recent years. Products with different product shapes, sizes, complex shapes and precision require Read more

Zirconia ceramics and materials containing zirconia ceramics are widely used. Due to the excellent physical and chemical properties of zirconia, it has a prominent position in engineering ceramics and advanced ceramics, such as industrial ceramic rods, ceramic plungers, and ceramic shafts. Wait. Due to its high melting point and chemical inertness, pure zirconia can be used as a refractory material, however, the transformation from tetragonal to monoclinic during thermal cycling can cause severe bulk cracking of the material. Many applications of zirconia therefore require it to be alloyed with alkaline earth oxides or rare earth oxides to give it a fully or partially stable structure. At present, the alloying elements Read more

The zirconia ceramic material has its own lubrication effect, so there is a great breakthrough in the fittings of the dispensing valve. The zirconia ceramic dispensing valve has a built-in cushioning and compensating elastic washer to ensure stable and good sealing performance, then the zirconia ceramic dispensing valve How should it be maintained? Nuoyi Precision Ceramics will share with you: The thickness of the ceramic dispensing valve shell exceeds the standard data requirements of GB, JB and American Standard ANSI, and the chemical elements and mechanical properties of the main material meet the specified standard requirements. First, use a wrench to unscrew the joint of the glue inlet, clean the Read more

Alumina ceramics are widely used due to their excellent properties such as high temperature resistance, strong hardness and light weight. The dielectric constant of alumina ceramics refers to a value of the degree of dielectric polarization of insulating materials under an AC electric field. The ratio of the capacitance of capacitors with the same electrode size when vacuum is used as the medium. It represents an inherent property of the material. The national standard stipulates that when the test frequency is 1MHz, the dielectric constant of the alumina ceramic structure is between 9-10. Alumina Ceramic Density The density of alumina is very small in special ceramics, only about half of Read more

Precision ceramic needle gauges are widely used because of their excellent properties such as flame retardant surface, good fire resistance, and no melting. They are the nemesis of most acid-base items and other chemicals. So what are the characteristics and uses of precision ceramic needle gauges? Woolen cloth? Precision Ceramics machining shop will share with you: Features of precision ceramic needle gauge 1. Ceramic material has good wear resistance, which is 5-10 times that of steel; good corrosion resistance, no special treatment is required for use and storage; good dimensional stability, due to the use of ultra-fine grained materials for ultra-precision finishing , so the surface is smooth and the Read more

Precision ceramic needle gauges are widely used because of their excellent surface properties such as flame retardant, good fire resistance, and no melting. They are the nemesis of most acid-base items and other chemicals. When using and maintaining and machining precision ceramic needle gauges What problems should we pay attention to? Nuoyi Precision Ceramics will share with you: The use of precision ceramic needle gauge: 1. Hold the measured part in the left hand and the ceramic needle gauge in the right hand, and at the same time align the circular hole of the part with the vertical, gently and slowly insert it. Measurement data; 2. Before use, you need Read more

The shaft body and sleeve of the zirconia ceramic shaft are made of zirconia ceramic material, and the retainer is made of polytetrafluoroethylene (PTFE), nylon 66, polyetherimide, zirconia, alumina, stainless steel or aviation-specific aluminum to make. What are the performance characteristics of zirconia ceramic shafts? Nuoyi Precision Ceramics will share with you: Zirconia ceramic shaft features: 1. High speed: It has the advantages of cold resistance, small force elasticity, high pressure resistance, poor thermal conductivity, light weight, and small friction coefficient. It can be used for high-precision equipment such as high-speed spindles ranging from 12,000 rpm to 75,000 rpm; 2. High temperature resistance: The use temperature between 1000℃-1200℃ will not Read more

Silicon carbide ceramics outperform other precision ceramic spare parts in some industrial applications. What are the uses of silicon carbide ceramics? Nuoyi Precision Ceramics will share with you: In air, silicon carbide begins to oxidize at 800°C, but at a very slow rate. The oxidation rate increases rapidly with increasing temperature. Silicon carbide oxidizes 1.6 times faster in oxygen than in air and slows down with time. The Use Of Silicon Carbide Ceramics 1. Abrasive: Due to its strong rigidity, it can be made into various abrasives such as grinding wheels and gauze, and is widely used in the machining industry. Refractory: Refractory black silicon carbide is generally divided into Read more

Zirconia is the raw material of zirconia ceramics, so it determines the performance structure of zirconia ceramics. There are many advantages of zirconia, and its usage and advantages are also different in different fields. Zirconia is the raw material of zirconia ceramics, so it determines the performance structure of zirconia ceramics. There are many advantages of zirconia, and its usage and advantages are also different in different fields. What are the advantages of zirconium dioxide? Advantages of zirconia In terms of structural ceramics, zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength, high wear resistance, excellent thermal insulation properties, and Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

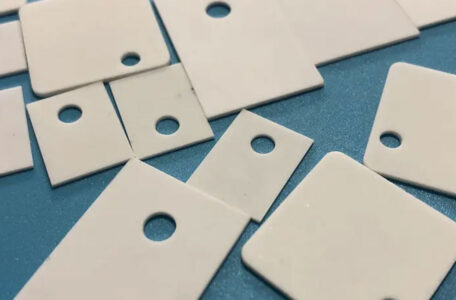

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

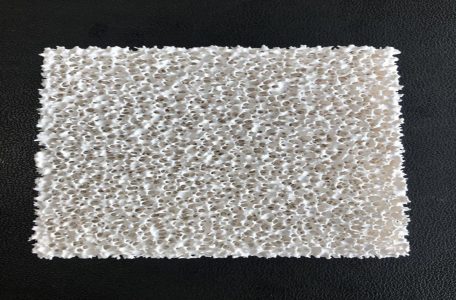

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump