Ceramic nozzle is a very common type of sprinkler in agricultural sprinkler facilities. This nozzle has good wear resistance and good chemical resistance, and is very popular. So what factors will affect the use of ceramic nozzles? Next, Pintejin Ceramics will introduce to you. Ceramic nozzles require maintenance, regular inspection, cleaning and even replacement in order to maintain the quality of the final product and maintain the economics of the production process. The manner and frequency of maintenance procedures depends on the application, and the maintenance schedule can be arranged according to the application, liquid and nozzle material. Reasons affecting the use of ceramic nozzles 1. Corrosion and wear: The Read more

Alumina special ceramics have excellent comprehensive performance, thermal conductivity, insulation, heat dissipation, high temperature resistance, and high pressure resistance. Next, Pintejin Ceramics will introduce the uses and application fields of alumina special ceramics. Application of alumina special ceramics Sapphire is a single crystal of alumina special ceramics, also known as corundum. As an important technical crystallization, sapphire has been widely used in many fields of science and technology, national defense and civil industries, and the use of alumina special ceramics (accessories in the electronics industry). Application fields of alumina special ceramics 1. Application of multi-chip encapsulated alumina special ceramics: The manufacturing methods of nano-alumina special ceramic multilayer substrates for encapsulation Read more

The tetragonal zirconia ceramic polycrystal has high strength and fracture toughness, but a certain stabilizer must be added in the preparation process to maintain the high performance of TZP. Below, Pintejin Ceramics Factory will introduce the tetragonal zirconia polycrystal and the How to keep its high performance. The grains of this ceramic material are very small. In order to keep the metastable tetragonal phase, ultra-fine and high-purity zirconia powder must be used, and the Y2O3 content must be accurately controlled. °C). alumina ceramic tube Tetragonal zirconia ceramics (TZP) have high strength and fracture toughness through transformation toughening, but at medium and high temperature due to the gradual disappearance of transformation Read more

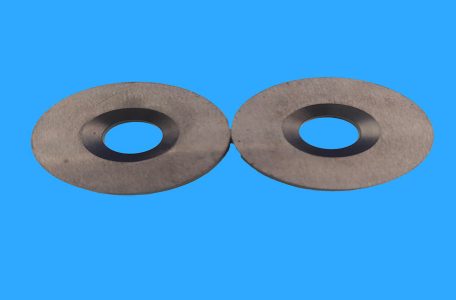

Ceramic blades have different names according to different shapes, such as round ones, also known as round ceramic blades. Usually zirconia ceramics or alumina ceramics, the following is a round ceramic blade introduced by Pintejin Ceramics Factory. Circular ceramic blades, also known as ceramic cutters, are widely used in industry, so what are their advantages? First, hard milling with round ceramic inserts can help mold shops reduce production costs in a number of ways. First, you can replace multiple processes with one process. When using round ceramic inserts for hard milling, the steel can be quenched first, and then the workpiece can be milled in the hardened state, thereby replacing Read more

Many industrial ceramics have corresponding toughened ceramic composite materials due to their brittleness, such as zirconia ceramic toughened alumina (ZTA) ceramics, and various silicon carbide composite materials, whose brittleness has been effectively improved, so what is What about silicon carbide composites? The following Pintejin Ceramics Factory will take you to understand. Due to the inherent brittleness of ceramic materials, their application in high-tech fields such as aerospace has been limited, so more attention has been paid to the toughening research of silicon carbide materials; the use of continuous and its fabric and braid toughening can not only improve the toughness of ceramic materials, but also The strength and modulus of Read more

The application of alumina ceramics in the current society has exceeded our imagination. It not only meets our daily use, but also meets various special requirements. So what are the factors that cause the cracking of alumina ceramics? Come down and introduce Pintejin Ceramics to you. 99 alumina ceramic material has high hardness, high strength, low expansion coefficient, insulation, wear resistance and corrosion resistance, and has a wide range of applications in machinery manufacturing, aerospace, precision instruments, petrochemical and other fields. However, alumina ceramic materials generally have a large elastic modulus, high hardness, high brittleness, and strong crack sensitivity. Therefore, the difficulty of machining is mainly manifested in Read more

Zirconia ceramic plunger has been widely used now, because its high temperature resistance and high wear resistance and stable chemical properties occupy a great advantage in the CNC industry, so what are the characteristics and applications of zirconia ceramic plunger? Next, Pintejin Ceramics will introduce it to you.The development and application of high-performance zirconia ceramic plungers have extended the service time of important components in oil extraction equipment, effectively reduced the number of shutdowns and pump inspections, and will generate greater economic benefits. Ceramic plunger has broad prospects and application value in heavy oil recovery. Zirconia ceramic parts Features of zirconia ceramic plunger: 1. The structure of the pump body Read more

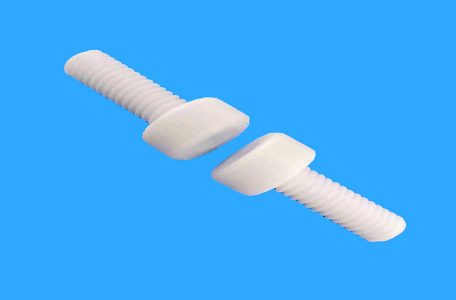

The selection of zirconia ceramic additives is one of the most important issues in zirconia Ceramic Injection Molding technology. Different zirconia ceramic molding methods require different additive properties. For example, injection molding requires degreasing, fluidity, peptization, strength, and shrinkage; extrusion requires plasticity, peptization, strength, and lubrication; cold isostatic pressing (rubber molding) requires lubrication, granulation, and strength; mechanical pressing requires lubrication. Granularity, strength, mold release, etc. At the same time, different adhesives should be used for different zirconia ceramic products. The requirements for additives in zirconia ceramic injection molding technology are as follows: Zirconia ceramic peptization It is advisable to use as few additives as possible for various molding methods of Read more

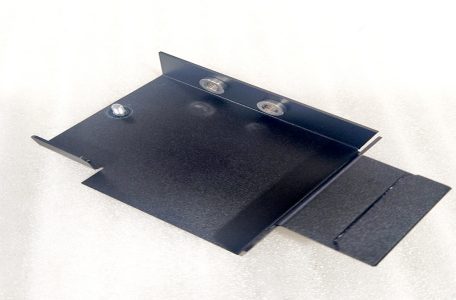

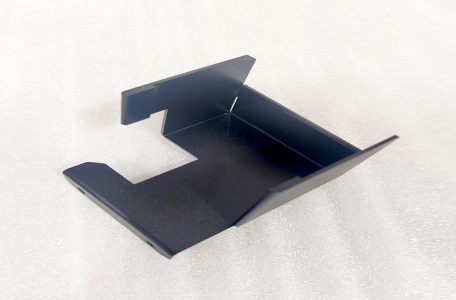

Zirconia ceramics have self-lubricating effects, so they can be used as dispensing valves and ceramic injection pumps. Below, Pintejin Ceramics Factory will show you what are the characteristics of lithium battery ceramic pumps? Lithium battery ceramic pump overview: A high-precision quantitative liquid injection pump, which can quantitatively perfuse or meter various liquids with different chemical and physical properties. It is widely used in liquid injection systems in electronics, food, chemical, pharmaceutical and other industries, especially high-performance batteries. Electrolyte injection in production. Lithium battery ceramic pump Lithium battery ceramic pump structure composition: The metering pump consists of three parts, named the pump drive, the middle part, and the pump head. The Read more

Many product materials must have a service life, so compared with other materials, zirconia ceramics have a long service life, what changes will there be? Let me introduce to you. Zirconia ceramic custom can generally be used for one year. Due to the death of the water stabilizer, although some of the remains will be swept away with the running water, some remain in the gap of the water stabilizer, and gradually deposit to the back to block the gap. The actual effect of parasitics in the ceramic ring will gradually decrease, so it is replaced on time. When it comes to ceramic raw materials, everyone is usually very easy Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump