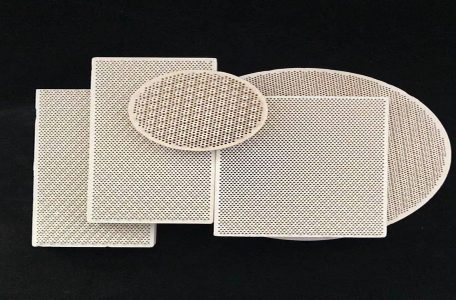

Ceramics are widely used in scientific research, industrial equipment and life due to their excellent characteristics such as high hardness and high wear resistance. The following Pintejin Zirconia Ceramics Factory will analyze what materials and properties of ceramics are. Zirconia material ceramic ring Ceramic materials refer to a class of inorganic non-metallic materials made of natural or synthetic compounds through shaping and high-temperature sintering. It has the advantages of high melting point, high hardness, high wear resistance and oxidation resistance. It can be used as structural material and tool material. Because ceramic also has some special properties, it can also be used as functional material. mechanical Ceramic materials are engineering Read more

Blog

When zirconia ceramics are sintered and formed, tensile specimens can be tested for their toughness. What conditions should be met in order to meet the needs of tensile specimens? Below Pintejin Ceramics Factory will give you an analysis. The shape of the zirconia ceramic tensile test piece and the shape of the blank are shown in Figure 3-18. In order to meet the needs of the tensile test, the tensile test piece should meet the following requirements: ①The surface of the tensile test piece should have a sufficiently low surface roughness ②The arc part should have an accurate profile ③ Tensile specimens should ensure axisymmetric accuracy. The metal bond diamond Read more

In the forming process of zirconia ceramic structural parts, both the sintering method and the cooling process will be used to obtain high-quality finished products. Next, Pintejin Ceramics will introduce the cooling and forming of zirconia ceramic structural parts. Zirconia ceramic structural parts, also known as engineering ceramics, fine ceramics, etc., are inorganic non-metallic materials with high temperature resistance, wear resistance, corrosion resistance and relatively stable chemical properties. 1. Vacuum cooling molding of zirconia ceramic structural parts The vacuum method of cooling and forming of zirconia ceramic structural parts adopts the method of vacuumizing the outside of the tube, so that the outer surface of the tube Read more

Sony’s flagship Xperia Z2 uses a low-key high-end ceramic heat pipe for heat dissipation. Similarly, the MediaX06E previously released by Japan’s NEC already used a zirconia ceramic heat pipe, known as the world’s first water-cooled mobile phone. Many radiator manufacturers have begun to predict that smartphones will use zirconia ceramic heat pipes to dissipate heat in the future. It’s just that the manufacturing technology of zirconia ceramic heat pipes was not advanced enough at that time, the diameter of heat pipes was more than 1.2mm, and there were too few manufacturers installed on mobile phones. Later, ceramic heat pipes with a diameter of 1.2mm were developed, but mobile phone manufacturers Read more

Generally, ceramic materials are specially customized. The process technology, strict production line and process of machining according to the drawings provided by customers are also an esoteric knowledge in ceramic production. How strong is the ceramic bulletproof board? Ceramic custom Personal protective equipment on the battlefield is especially important for soldiers. At critical moments, they may bring life to the wearer. Therefore, troops engaged in front-line operations will basically be equipped with complete protective equipment, including bulletproof helmets, bulletproof vests, etc.In one operation, the special forces of the Afghan government forces had already deployed combat units under the 19th Special Forces Squadron of the US Army to fight against the Read more

Zirconia ceramics can theoretically withstand high temperatures of up to 1350 degrees, so is its heat resistance in use really that strong? The following Pintejin Ceramics Factory will give you an analysis. The thermal stress in the zirconia ceramic material depends on the mechanical and thermal properties of the material, and is affected by the geometry of the structural parts and the environmental medium. The thermal shock resistance, which is the ability of ceramic materials to resist temperature changes, is a comprehensive performance of the mechanical properties and thermal properties of ceramic materials. The thermal vibration damage of zirconia ceramic materials is divided into two categories: instantaneous fracture under thermal Read more

Zirconia ceramic materials can be processed into many structural ceramics, which replace traditional metal materials in many aspects. Below, Pintejin Ceramics Factory will tell you the difference between zirconia ceramic injection pumps and metal pumps. The difference between ceramic injection pump and metal pump: Ceramic injection pumps have developed by leaps and bounds in recent years, and most of the plunger pump industry uses metal plunger pumps. Although the metal plunger pump has been improved in structure and material, it is limited by the properties of metal materials and cannot meet the needs of increasingly high wear, strong corrosion and other harsh working conditions. It is mainly reflected in the Read more

Ceramic jars are made of new ceramics for industrial ceramics. Pintejin Ceramics is a manufacturer specializing in the production and machining of zirconia ceramics. Below, Pintejin Ceramics will introduce you to industrial ceramic jars. Ceramic grinding jars Our common ceramic jars are made of pottery clay, made into a round belly, coated with black or yellow glaze, and fired in a kiln to hold or cook food. Ceramic jar is a modern new type of jar, which is made of industrial ceramic materials. There are covered and uncovered, with various forms and uses. Pintejin Ceramics can produce ceramic parts and structural parts of various shapes and sizes according to customer Read more

With the rapid development of my country’s industrial field, traditional metal materials cannot meet our performance requirements, while ceramic materials have a variety of excellent properties and are widely used in industrial fields. Now Pintejin Ceramic Zirconia Processing Factory will tell you about industrial ceramic parts. Industrial ceramic parts positioning pins Because industrial ceramic parts have a series of advantages such as high temperature resistance, corrosion resistance, wear resistance, erosion resistance, etc., they can replace metal materials and organic polymer materials in harsh working environments, and have become traditional industrial transformation, emerging industries and high-tech. It is an indispensable and important material in energy, aerospace, machinery, automobile, electronics, chemical industry Read more

Industrial ceramics will have many characteristics and advantages after being used to make ceramic plungers, including its use and performance. Pintejin Ceramics Factory will give a brief introduction to industrial ceramic plungers. The ceramic plunger adopts modern engineering ceramic material with super hard wear resistance, and can be assembled and formed by ceramic metallization bonding, welding, inlay and socket technology. It is an ideal substitute for similar metal pumps, and has been widely used in medical equipment, environmental engineering, petroleum, chemical and other industries. Ceramic plunger Industrial ceramic plunger has the following characteristics: (1) The ceramic plunger adopts high-performance technical ceramic material, which has the properties of high hardness, wear Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump