Ceramic rods are very particular in the process of production and material selection. The produced ceramic rods are both good and bad, so how to identify the pros and cons of ceramic rods? Below Pintejin Ceramics Factory will give you an analysis. Due to the lack of a certain understanding of ceramic rods, I do not know how to choose when purchasing, resulting in the quality of the final ceramic rods that do not meet the requirements. The following small series will introduce you to several methods of selecting ceramic rods, hoping to help you. Fine zirconia ceramic rod The first is to verify the quality of the ceramic rod Read more

The ceramic sealing ring is mainly used as a sealing device, and acts as a matching object in some harsh environments to achieve a sealing effect between the two parts. It is mainly made of high temperature resistant zirconia ceramics and alumina ceramics. Then the following Pintejin Ceramics Factory Its application range and performance characteristics will be analyzed in detail. Ceramic sealing ring for mechanical structure is superior to other materials in chemical corrosion resistance, wear resistance, high temperature resistance and other properties. It is processed from ceramic powder through vacuum hot pressing sintering, grinding, polishing and other processes. Widely used in machinery, chemical, petroleum, food, pharmaceutical, automotive and other Read more

High temperature resistant industrial ceramics refers to ceramics with high temperature resistance for industrial production and industrial products. Now Pintejin Zirconia Ceramics Factory will tell you the common high temperature resistant industrial ceramics. High temperature-resistant industrial ceramics are a type of fine ceramics, which can play mechanical, thermal, chemical and other functions in applications. Because industrial ceramics have a series of advantages such as high temperature resistance, corrosion resistance, wear resistance and erosion resistance, they can replace metal materials and organic polymer materials in harsh working environments. 99 alumina high temperature industrial ceramic flange Alumina Ceramics: The ceramic is a ceramic with AL2O3 as the main component (the mass fraction Read more

Alumina ceramics is a kind of ceramic products using alumina as the main material. Next, Pintejin Ceramics will introduce the molding method of alumina ceramic materials. Forming method of alumina ceramic material 1. Dry-pressing molding: The thousand-pressing molding technology of alumina ceramic materials is limited to objects with a simple shape, an inner wall thickness of more than 1mm, and a length-to-diameter ratio of not more than 4:1. The molding method is uniaxial or bidirectional, and the press has two types: hydraulic and mechanical, which can be semi-automatic or fully automatic. The maximum pressure of the press is 200Mpa. Due to the uniform stroke pressure of the Read more

When the zirconia ceramic is polished to a mirror effect, its appearance will be as bright as jade, and the finish is generally below Ra0.1, so what methods can be used to obtain bright and clean zirconia ceramics? The following Pintejin Ceramics Factory will introduce 5 methods to you. However, after the zirconia ceramics are sintered and cooled, it does not mean the end of product machining. Some products still do not meet the application requirements, so they need to be processed, such as size correction, polishing, etc. Black zirconia ceramic plunger rod 1. Grinding and polishing by laser machining and ultrasonic machining. 2. Use zirconia powder or diamond paste Read more

For different kinds of machinable ceramics, there are different machinability mechanisms, mainly including the following: machinable ceramics with lower elastic modulus; weak interphase interfacial peeling caused by thermal mismatch in multiphase ceramics; Mn+lAXn , the processability of such compounds, etc. The needle-like or flake-like mica crystals with large aspect ratio are uniformly precipitated from the glass phase to form a staggered layered structure. During machining, multiple micro-cracks are generated around the grains in contact with the cutting edge of the tool, and the cracks are bifurcated and bridged, resulting in the spalling of the matrix grains. Through research, Padture et al. pointed out that the weak interface, long grains and Read more

Zirconia ceramic performance: Pure ZrO2 is white, yellow or gray when it contains impurities, and generally contains HfO2. It is not easy to separate. Next, Pintejin Ceramics will introduce the grinding method of zirconia ceramics. The flatness of zirconia ceramics that can be directly fired is very good, so many post-film integrated circuits, refrigerators and ozone generators are processed by zirconia ceramics, which can be said to be made of this ceramic material. The product has advantages over other materials. The most common knives in daily life are the knives made of zirconia ceramics. They are not only stronger, they will not rust after a period of use, Read more

With the continuous development and progress of science and technology, alumina ceramic parts with superior performance have been widely used in various fields, then Pintejin Ceramics will introduce the sintering method of alumina ceramic parts to you. Sintering method of alumina ceramic parts 1. Activated hot pressing sintering Activation sintering is a relatively traditional sintering method, and activation hot pressing sintering is a new process developed on this basis.If alumina ceramic manufacturers use this method to sinter alumina ceramic parts, the reactants will have a relatively high energy activation state when a decomposition reaction or phase transition occurs.At this time, hot pressing can be used to obtain high-density alumina ceramic Read more

In recent years, industrial ceramic rods have been widely used, because they are high temperature resistant ceramics and have many advantages, they have been used in electronic appliances, aerospace, medical equipment and other industries, but different materials have different specifications and different technical requirements. The prices of different ceramic rods are different. Below, Pintejin Ceramics Factory will analyze which factors will affect the price? The first is the cost of raw materials. The concept of environmental protection has gradually taken root in the hearts of the people, and equipment with high efficiency and low pollution is increasingly welcomed by consumers. However, the raw materials used in this environmentally friendly ceramic Read more

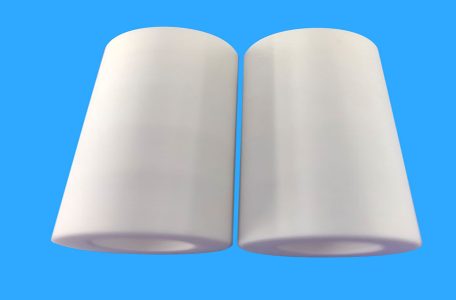

Industrial ceramic rods have been widely used now, and are involved in military, aerospace, industry, etc., mainly zirconia ceramic rods and alumina ceramic rods, so what are the advantages of each of them? Pintejin Ceramics Factory will explain it to you. The high temperature resistance of alumina ceramic rods can reach more than 1700 degrees, and it has good conductivity, mechanical strength and surface high temperature. Alumina ceramic rods are widely used in various fields such as electronic, electrical and mechanical accessories. Zirconia ceramic rods have better grinding performance and high hardness, high compressive strength and high density of more than 6.0. The biggest advantage of zirconia ceramics is that Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump