The common thermal conductive ceramic gasket is alumina ceramic material. Because the thermal conductivity of alumina material is very high, it can be used as a thermal conductive and heat dissipation gasket. The following Pintejin ceramic zirconia machining factory will tell you about the thermal conductivity of alumina thermal conductive ceramic gasket. Where is the advantage. Alumina thermal conductive ceramic gasket: high alumina content, relatively dense structure and special properties, so it is called special ceramics. The alumina thermal conductive ceramic gasket material is a close-packed hexagonal structure composed of oxygen ions, and aluminum ions are filled in two-thirds of the octahedral gap, which is the same stable α-Al2O3 structure Read more

Nowadays, the development of new industrial ceramics is very rapid, and their wear resistance is also an important property. Below, Pintejin Ceramics Factory will introduce to you which of the two industrial ceramics, zirconia ceramics and alumina ceramics, has better wear resistance.Zirconia fine ceramic rods Comparison of wear resistance between alumina ceramics and zirconia ceramics: 1. Natural alumina is corundum with a Mohs hardness of 9 and cubic zirconia with a Mohs hardness of 8.5. Therefore, in terms of pure alumina and zirconia, alumina is harder and more wear-resistant. 2. But alumina ceramic is a mixture, it is artificially made by batching and then sintered, not pure brittle corundum. Therefore, Read more

The strength and toughness of single crystal zirconia ceramics are based on its crystal structure. Because of its special crystal structure, it can be made into ceramic parts suitable for various harsh environments. Crystal structure. There are three stable allotropes of zirconia: the monoclinic phase (m), the cubic phase (c), and the tetragonal phase (f)9. The monoclinic phase of pure zirconia is stable from room temperature to 1170 °C, above this temperature it transforms into tetragonal phase, and then transforms into cubic phase at 2370 °C until melting occurs at 2680 °C. There is a hysteresis phenomenon when the ceramic bearing column changes from monoclinic phase to tetragonal phase. Upon Read more

As mentioned earlier, one of the necessary conditions for achieving ceramic sintering is that there should be mass transfer during the sintering process. Under the action of the sintering driving force, only through the material transfer process can the pores be gradually filled, so that the green body becomes dense from loose. At present, the research on the sintering mechanism, that is, the research on the mode and mechanism of material transfer in the sintering process, has four main theories, namely evaporation and condensation, diffusion, viscous flow and plastic flow, dissolution and precipitation. It should be pointed out that the material transfer phenomenon in the actual sintering process is quite Read more

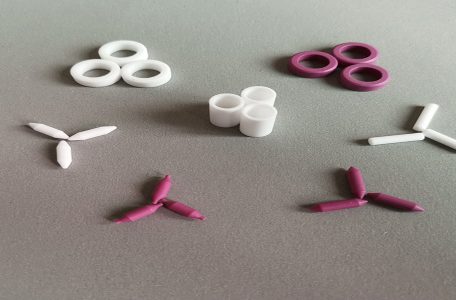

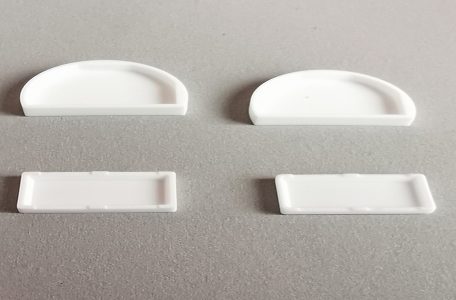

Since zirconia ceramics have relatively unique properties, and they have been valued in the market, the most important thing is to attract the development and research of researchers, so how can zirconia ceramics be polished into a mirror surface? Next, Pintejin ceramics will introduce to you a bit. The basic method of ceramic material machining: ceramic materials usually need to go through blank cutting, grinding, grinding and polishing and other processes to make the required parts. Product categories: ceramic plungers, ceramic pump cores, ceramic valve cores, ceramic pistons, ceramic bushings, ceramic suction cups, microporous ceramics, etc.; materials: alumina, zirconia, silicon nitride, silicon carbide. Grinding and polishing is a super-finishing method Read more

95 alumina ceramic is a widely used ceramic in structural ceramics, because it has excellent electrical properties at high frequencies, low dielectric loss, high volume resistivity, high strength, high hardness, and low linear expansion coefficient. So what is the process of hot pressing of 95 alumina ceramics? Next, Pintejin Ceramics will introduce to you. The molding methods of 95 alumina ceramics include dry pressing, hot die casting, pouring, extrusion, etc. In recent years, pressure filtration molding, direct solidification injection molding, gel injection molding, centrifugal grouting and solid free molding have been developed at home and abroad in recent years. Products with different product shapes, sizes, complex shapes and precision require Read more

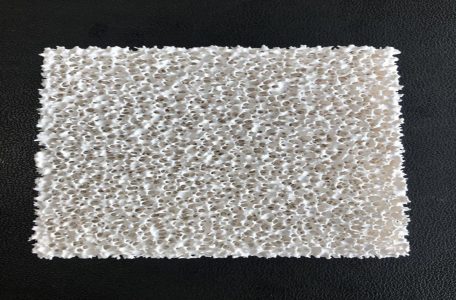

Silicon carbide ceramics outperform other precision ceramic spare parts in some industrial applications. What are the characteristics of silicon carbide porous ceramics? Nuoyi Precision Ceramics will share with you: Silicon carbide porous ceramic material is made from corundum sand, silicon carbide, cordierite and other raw materials through molding and special high temperature sintering process. It has the advantages of high temperature resistance, high pressure resistance, acid, alkali and organic medium corrosion resistance, good biological inertness, controllable pore structure, high porosity, long service life, and good product regeneration performance. Filtration and separation of various media, noise reduction of high-pressure gas exhaust gas, gas distribution and electrolytic membrane, etc. Properties Of Silicon Read more

Silicon Nitride (Si3N4) has the most versatile combination of mechanical, thermal and electrical properties of any technical ceramic material. It is a high-performance technical ceramic, very hard, with excellent thermal shock and impact resistance. It exceeds the high temperature capabilities of most metals and has excellent creep and oxidation resistance. Additionally, its low thermal conductivity and high wear resistance make it an excellent material to withstand the harshest conditions in the harshest industrial applications. Silicon nitride is an excellent choice when high temperature and high load capacity are required. Silicon Nitride is one of the hardest technologies available for ceramics and has been used successfully for many years in a Read more

Ceramic Machining Industry

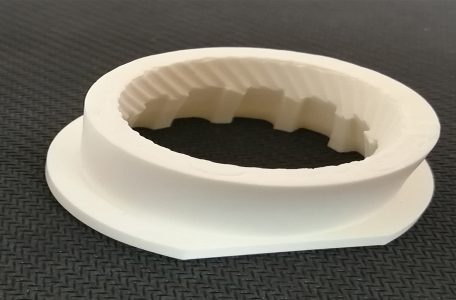

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump