Nowadays, the development of new industrial ceramics is very rapid, and their wear resistance is also an important property. Below, Pintejin Ceramics Factory will introduce to you which of the two industrial ceramics, zirconia ceramics and alumina ceramics, has better wear resistance.

Zirconia fine ceramic rods Comparison of wear resistance between alumina ceramics and zirconia ceramics: 1. Natural alumina is corundum with a Mohs hardness of 9 and cubic zirconia with a Mohs hardness of 8.5. Therefore, in terms of pure alumina and zirconia, alumina is harder and more wear-resistant. 2. But alumina ceramic is a mixture, it is artificially made by batching and then sintered, not pure brittle corundum. Therefore, depending on the alumina content of ceramics, some manufacturers have 95% alumina ceramics, 97% alumina ceramics, 99% alumina, 99.7% alumina ceramics and other ceramics. The hardness of zirconia ceramics is also very high. 3. If the grinding medium material working under centrifugal force is preferably zirconia, its monoclinic crystal density is 5.85. The density of alumina is only 3.9-4.0. Therefore, choosing zirconia as the grinding medium will generate greater shear force and improve the grinding efficiency. 4. If it is used as the material of grinding jars, bearings and other components, it will be better to choose high-purity alumina ceramics with higher hardness.

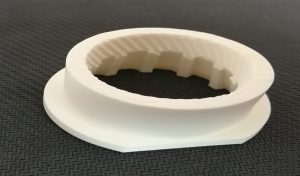

According to the above comparison, you must have a certain understanding of the two industrial ceramics. Pintejin Ceramics Factory mainly processes zirconia ceramics. The main products are: wear-resistant zirconia ceramic rods, wear-resistant zirconia ceramic plates, wear-resistant zirconia ceramics alumina ceramic sheets, wear-resistant alumina ceramic tubes, alumina ceramic sheets, alumina ceramic substrates and other zirconia ceramic manufacturers.

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies