The characteristic of rotary ultrasonic machining is that its ultrasonic head rotates with the spindle during operation. A large number of test results show that in the process of machining, the removal effect of simple tool rotation or ultrasonic vibration is relatively poor, but after the combination of the two, the situation has been greatly improved. Compared with traditional ultrasonic machining, rotary ultrasonic machining has the following advantages: The machining speed is fast. Ultrasonic rotary machining retains the advantages of traditional ultrasonics, that is, both conductive and non-conductive materials can be processed, and the machining speed can reach more than 100mm/min. The machining speed of ultrasonic rotary machining is 10 Read more

Blog

Zirconia ceramic shaft standard parts refer to the commonly used zirconia ceramic shafts that have been completely standardized in structure, size, drawing method, marking and other aspects, and are produced by professional factories. They have light structure, good electrical insulation performance and small thermal expansion coefficient. , Non-magnetic, non-conductive, high speed, low noise, high temperature resistance, wear resistance, acid, alkali, salt corrosion, non-toxic, dimensional stability under high temperature and other characteristics. It works under harsh lubrication conditions and has excellent dry running performance. It can be widely used in aviation, aerospace, navigation, automobile, machine tool, petroleum, chemical, electric power, metallurgy, textile, medicine, scientific research and military technology. International advanced level Read more

Many people will ask is ceramics a conductor? Is ceramic insulating? Let Pintejin Zirconia Ceramic Factory answer everyone: Ceramics are not conductors. The insulation properties of ceramics are introduced below. Insulating ceramics, also known as device ceramics, are ceramic materials used in electronic equipment to install, fix, support, protect, insulate, isolate and connect various radio components and devices. Insulated zirconia ceramic tube To be an excellent insulating ceramic, it must have the following properties: 1. High volume resistivity ≥1012Ω·m; 2. Small relative permittivity εr≤30; 3. Loss factor tgδ ≤0.001; 4. High dielectric strength ≥500kV/cm, good thermal conductivity: thermal conductivity is 24~28W/m·K; corrosion resistance, no deformation, can be used in the Read more

The fluid zirconia ceramic dispensing valve mainly solves the automatic fluid control scheme, and is also a major breakthrough in industrial automation equipment. It matches different fluid dispensing valves for different viscous fluid materials, glue output requirements, and accuracy. The automatic integration of zirconia is very important, which solves many problems for many enterprise users, such as shortage of personnel and labor, low efficiency of manual dispensing operation, low qualified rate of products, large waste of fluid raw materials, etc., which improves the product quality and production capacity of enterprises, reduces the In view of the production cost and manufacturing cost, only continuous research and development innovation and intensive cultivation Read more

Zirconia ceramic performance: pure ZrO2 is white, yellow or gray when it contains impurities, and generally contains HfO2. It is not easy to separate, so what are the advantages of zirconia ceramic high temperature insulating parts? Advantages of zirconia ceramic high temperature insulating parts 1. Due to the high hardness of zirconia ceramics, it can be made into cold forming tools, shaping dies, wire drawing dies, cutting tools, grinding media, golf club heads, etc. 2 Zirconia ceramics have high strength and good toughness, so they can be used to manufacture engine components, such as push rods, connecting rods, bearing cylinder liners, piston caps, etc. 3. Zirconia ceramics also have semiconducting Read more

With the wide application of difficult-to-machine materials such as titanium alloys and superalloys, how to correctly select and reasonably use tools for efficient and high-quality machining has become a very important industry topic. The workpiece material and tool structure, materials, etc. promote each other, the development of the manufacturing industry is very rapid, and the continuous development of tools is the driving force for the continuous development of the manufacturing industry. At present, the tool materials widely used in the manufacturing industry mainly include tool steel (carbon tool steel, alloy tool steel and high-speed steel), cemented carbide, ceramics and superhard tool materials. Among them, cemented carbide tools account for the Read more

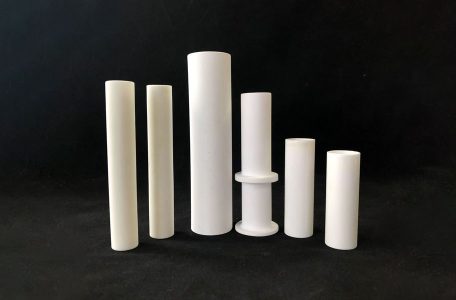

Pintejin Ceramics specializes in the production of ceramic rods and ceramic center rods, and has large quantities of ceramic rods in stock. High temperature sintered ceramic rods are widely used in aerospace, medical equipment, military machinery and other fields. Pintejin has a large inventory of ceramic rods, the diameter can be 0.4mm, and the length can be formed over 400mm! Pintejin Ceramics has advanced ceramic forming, sintering, and ceramic machining equipment; our machining experience is rich, and can be turned, milled, planed, and ground , drilling, cutting, tapping and other machining and achieve high precision; dimensional accuracy: up to 0.001; smoothness: up to atomized mirror surface! Pintejin Ceramics has advanced Read more

Pintejin Ceramics Factory is a manufacturer of ceramic parts. In the process of production and machining, the production equipment used is also very important. Today, I will explain the equipment problems and advantages of producing zirconia ceramic parts. The sand mill can use glass marbles, zirconia balls, and bearing steel balls as grinding materials. It is better to use a uniform particle size for each material. Before loading the material into the head, the material should be cleaned and selected in advance. The selection of a certain type of material during grinding depends on the permeability particle size and viscosity of the raw material to be milled. The standard is: Read more

Toughening principle of alumina ceramic junction Alumina ceramics is a kind of ceramics with a wide range of uses. Because of its superior properties, it has been widely used in modern society to meet the needs of special properties. With the use and technology of alumina ceramics becoming more and more mature, some indicators still need to be improved, which requires joint research. At the same time, about some performance parameters of alumina ceramics, I also hope that everyone can clearly put forward, so that researchers and manufacturers can study and design according to the requirements of users, so as not to have no purpose. By adding or generating particles, Read more

The products of alumina ceramic manufacturers include 95-99 alumina ceramics. I believe that everyone does not know the price of alumina ceramic manufacturers’ products very well. If you want to know what their prices are, the following is a professional manufacturer of zirconia. The manufacturer of ceramics and alumina ceramics, Pintejin Ceramics Factory, will introduce the price of alumina ceramics manufacturers. Alumina ceramic tube 1. If the price of 95 alumina ceramics from alumina ceramic manufacturers is 95 alumina ceramics from alumina ceramic manufacturers, then its price is relatively cheap, generally more than a dozen pieces, but It depends on what the market is like in each place. This will Read more

Ceramic Machining Industry

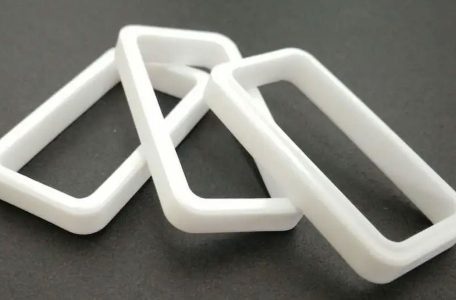

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

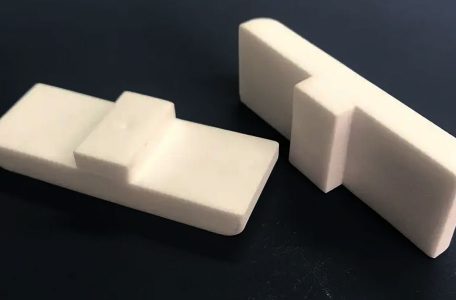

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump