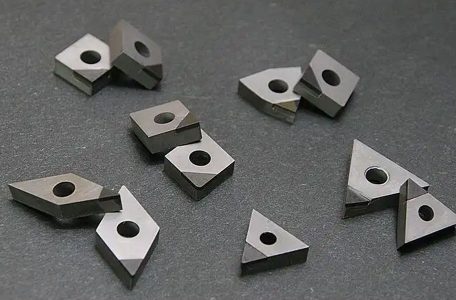

Cemented Carbide Alloy is a multi-phase composite material produced by powder metallurgy with refractory metal carbide as matrix and hard phase, cobalt (nickel) as binder phase (often sintered in vacuum furnace or hydrogen reduction furnace and produced by powder metallurgy). powder metallurgy products). Carbide is widely used as tool material, such as turning, milling, planing, boring and other tools and drills, for cutting ordinary steel, cast iron, non-ferrous metals and plastics and other materials, and even for cutting tool steel, stainless and heat-resistant steel Difficult-to-machine materials (materials up to 50 HRC can be cut). The cutting speed of carbide tools is 4-7 times higher than that of high-speed steel, and Read more

Blog

Ceramic micro-injection molding (μCIM) is a new technology developed on the basis of conventional CIM. After the information revolution, more and more micro-components (10-1000 μm) in the microelectronics industry use structural ceramic materials. Compared with ceramic parts prepared by traditional micromachining technology, there are high cost, low efficiency and difficult to unify size. shortcoming. The ceramic micro-injection molding technology developed in recent years can obtain blanks of various shapes (including complex shapes) at one time, with high dimensional accuracy and uniform microstructure, and can realize automatic and large-scale production. A very promising advanced molding manufacturing technology [35-36]. The biggest difference between low pressure injection molding (LPM) and traditional injection molding Read more

Injection Process The injection process includes three stages of injection, pressure holding and cooling and setting, that is, the powder is heated and softened first, then injected into the mold, held in the mold for a period of time, and finally cooled to prepare a blank with the desired shape. Every stage of the injection process is critical, and improper control can lead to cracks, delamination, separation of powders and organic binders, and many other defects in ceramic parts. Wang Hekun et al. [22] found through a large number of experiments that compared with the injection speed and the holding pressure, the injection temperature and injection pressure are the keys Read more

Mixing the ceramic powder and the binder is the first step in the injection molding process, which relies on the wetting ability between the ceramic powder and the binder and the action of external mechanical force. Since the defects generated during the mixing process cannot be eliminated by subsequent processes, the mixing stage is also the key to determining the quality of injection molding. The main defect of the mixing process is the non-uniformity of the mixture, including the separation of powder and binder and the segregation of powder in the binder caused by particle size, which will affect the density reduction and structural deformation of the final ceramic part. Read more

According to the composition and properties of the binder, the binder can be divided into: thermosetting system, thermoplastic system and water-soluble system. Thermoset systems refer to a class of ceramic binders in which the matrix component is a thermoset resin, and has properties similar to thermoset resins. This feature makes the structure highly solidified after heating, which reduces the deformation of the green body during the debinding process and provides the required carbon element for reactive sintering; But its disadvantages are poor fluidity and formability, difficulty in mixing with powder, and long degreasing time [17]. Thermoplastic resin is a binder with thermoplastic organic compounds as the main body, and its Read more

The binder used in ceramic injection molding is usually an organic polymer compound, the purpose is to mix with the ceramic powder, increase the fluidity, help the injection molding stage to proceed smoothly, and keep the shape of the green body stable after molding and during degreasing. . When preparing and selecting a binder, the following points need to be considered: The binder itself should have good fluidity. In general, the fluidity of the binder is negatively correlated with the number of molecular weights, and also has a certain relationship with the distribution of molecular weights. The binder has good wettability with the ceramic powder. The addition of the binder Read more

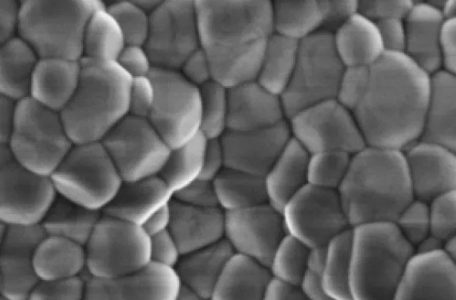

The shape, size and particle size distribution of ceramic powder are an important factor affecting the quality of injection molding. The addition of organic binders will cause the dimensional shrinkage of ceramic injection molded products after sintering to be much greater than that of molded products. In order to prevent the deformation and dimensional accuracy decline caused by a large amount of shrinkage, the content of solid powder in the material system must be increased to reduce shrinkage [6]. In theory, spherical powder can maximize the loading capacity, but there is another problem that the meshing force between the spheres is very small, and it is difficult to maintain the Read more

ISO9001 certification is one of the core standards of a group of quality management systems included in the ISO9000 family of standards. The ISO9000 family of standards is a concept proposed by the International Organization for Standardization (ISO) in 1994, which refers to “international standards formulated by ISO/Tc176 (International Organization for Standardization Quality Management and Quality Assurance Technical Committee). It is not difficult for enterprises to obtain ISO9001 certification. , but it is not as easy as imagined, and many corporate customers have reported that they encountered many difficulties when applying for ISO9000 certification. Pintejin has passed the ISO9001 certification in November 2009, and every step is the result of Read more

Silicon Nitride (Si3N4) has the most versatile combination of mechanical, thermal and electrical properties of any technical ceramic material. It is a high-performance technical ceramic, very hard, with excellent thermal shock and impact resistance. It exceeds the high temperature capabilities of most metals and has excellent creep and oxidation resistance. Additionally, its low thermal conductivity and high wear resistance make it an excellent material to withstand the harshest conditions in the harshest industrial applications. Silicon nitride is an excellent choice when high temperature and high load capacity are required. Silicon Nitride is one of the hardest technologies available for ceramics and has been used successfully for many years in a Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump