The use of ceramic molds was adopted in the late Longshan culture, but there is no specific discussion. Until the Shang Dynasty, due to the increasing number of decorative patterns and patterns on the surface of ceramic utensils, pottery impressions and pottery paddles for printing various patterns on the surface of ceramic utensils began to appear. The concept of pottery impression mold was accurately proposed in the middle of the Shang Dynasty. It was originally used as a casting tool for bronze ware. In the Xia Dynasty, ceramic utensils were used as crucibles to smelt bronze. In the late Shang Dynasty, ceramic utensils were used as crucibles. Based on this, Read more

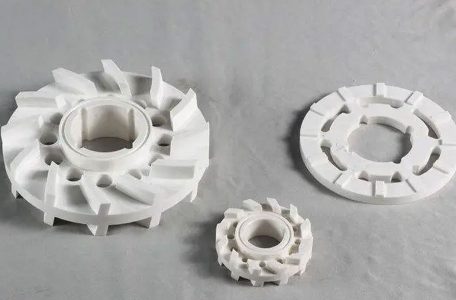

In today’s daily life, the daily utensils and pottery ceramic products we use are formed by hand molding and mold molding. The uniqueness of hand-shaped ceramic products is that mold forming can be used by ceramic workers for repeated use to produce multiple pieces of the same ceramic product. The mold forming process mainly relies on the gypsum solidified in a short time as the mold, and the water absorption of the gypsum is used to absorb the water of the cast or printed mud blank, so that the mud blank is dry and hard to form. Ceramic molds are divided into three categories: Machine press production: male and female Read more

China is a big country with a long history of producing ceramics. From the very beginning, human beings realized in practice that clay mixed with water has a certain plasticity and can shape a certain shape of utensils. Beginning with the ancient and simple molding process, the molding process of ceramics has been With the development of ceramics, it has gradually evolved, from low-level craftsmanship to high-level craftsmanship, such as the early kneading molding or partial molding, and later the development of using clay strips and clay plates to shape and so on. With the continuous updating of modern art forms, creative ideas emerge in an endless stream, but there Read more

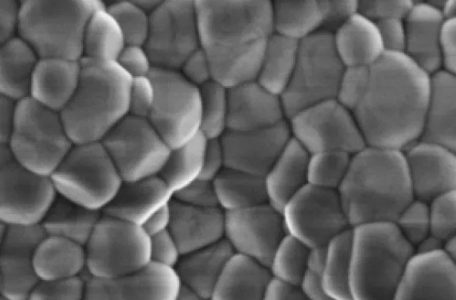

Ceramic micro-injection molding (μCIM) is a new technology developed on the basis of conventional CIM. After the information revolution, more and more micro-components (10-1000 μm) in the microelectronics industry use structural ceramic materials. Compared with ceramic parts prepared by traditional micromachining technology, there are high cost, low efficiency and difficult to unify size. shortcoming. The ceramic micro-injection molding technology developed in recent years can obtain blanks of various shapes (including complex shapes) at one time, with high dimensional accuracy and uniform microstructure, and can realize automatic and large-scale production. A very promising advanced molding manufacturing technology [35-36]. The biggest difference between low pressure injection molding (LPM) and traditional injection molding Read more

Injection Process The injection process includes three stages of injection, pressure holding and cooling and setting, that is, the powder is heated and softened first, then injected into the mold, held in the mold for a period of time, and finally cooled to prepare a blank with the desired shape. Every stage of the injection process is critical, and improper control can lead to cracks, delamination, separation of powders and organic binders, and many other defects in ceramic parts. Wang Hekun et al. [22] found through a large number of experiments that compared with the injection speed and the holding pressure, the injection temperature and injection pressure are the keys Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump