- Machine press production: male and female molds

- Grouting production: solid grouting and hollow grouting

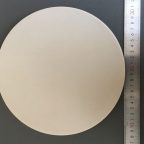

- Printing blank molds

Insufficiency of research on the value of ceramic mold forming process

We should clearly find that there are some deficiencies in the research of ceramic forming process, especially for the mold forming process to be discussed in this paper. Looking through many reference materials, although there are many reference books on ceramic molding technology, most of them only introduce the production process, and there is no theoretical description of the reflection of the value of the production process. Mould forming is not just a technique, starting from itself, we make a systematic discussion and discussion to study how the creation of thinking diffusion as a ceramic artist can be completed through the ceramic mould forming process, and how industrialized ceramic products can be produced through the ceramic mould forming process. Mass production. To link its development with the features and artistry it embodies, to discuss and systematically conduct in-depth research on the mold forming process as a subject, is the purpose of our manufacturer’s writing.

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies

Wear-resistant zirconia ceramic cutters manufacturers claim that zirconia ceramic cutters are ceramic inserts for high-tech Read more

Sheet forming also belongs to plastic forming. The prepared billet is mixed with a certain Read more

For ceramic knives, how much do you know about ceramic knives in addition to their Read more

With the advancement of modern technology, ceramic nozzles are more and more widely used, and Read more

Classification of advanced functional ceramics: (l) Piezoelectric ceramics Piezoelectric ceramics refers to a functional ceramics Read more

The properties of zirconia ceramic powder are very important to the quality of the advanced Read more

Zirconia ceramic materials can be processed to produce industrial ceramic parts, such as zirconia ceramic Read more

Structural ceramics refer to ceramics used in various industrial sectors to manufacture mechanical equipment and Read more