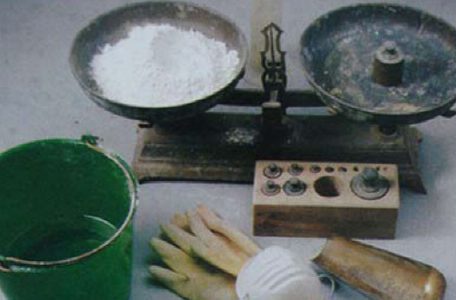

Prepare to weigh a good proportion of water and gypsum, slowly sprinkle the gypsum into the bucket with the relative proportion of water, and pay attention to rubbing your hands during the pouring process to further screen the impurities in the gypsum. It is not advisable to stir the gypsum in the process of spreading it. Slowly sink it into the water until no powdery gypsum can be seen. At this time, stir it by hand or with a mixer to make it blend with the water. While stirring, pay attention to the particles and other particles when mixing. To remove impurities, stir evenly at a frequency so as not Read more

All posts in Injection Molding Guide

Mixing the ceramic powder and the binder is the first step in the injection molding process, which relies on the wetting ability between the ceramic powder and the binder and the action of external mechanical force. Since the defects generated during the mixing process cannot be eliminated by subsequent processes, the mixing stage is also the key to determining the quality of injection molding. The main defect of the mixing process is the non-uniformity of the mixture, including the separation of powder and binder and the segregation of powder in the binder caused by particle size, which will affect the density reduction and structural deformation of the final ceramic part. Read more

According to the composition and properties of the binder, the binder can be divided into: thermosetting system, thermoplastic system and water-soluble system. Thermoset systems refer to a class of ceramic binders in which the matrix component is a thermoset resin, and has properties similar to thermoset resins. This feature makes the structure highly solidified after heating, which reduces the deformation of the green body during the debinding process and provides the required carbon element for reactive sintering; But its disadvantages are poor fluidity and formability, difficulty in mixing with powder, and long degreasing time [17]. Thermoplastic resin is a binder with thermoplastic organic compounds as the main body, and its Read more

The binder used in ceramic injection molding is usually an organic polymer compound, the purpose is to mix with the ceramic powder, increase the fluidity, help the injection molding stage to proceed smoothly, and keep the shape of the green body stable after molding and during degreasing. . When preparing and selecting a binder, the following points need to be considered: The binder itself should have good fluidity. In general, the fluidity of the binder is negatively correlated with the number of molecular weights, and also has a certain relationship with the distribution of molecular weights. The binder has good wettability with the ceramic powder. The addition of the binder Read more

The shape, size and particle size distribution of ceramic powder are an important factor affecting the quality of injection molding. The addition of organic binders will cause the dimensional shrinkage of ceramic injection molded products after sintering to be much greater than that of molded products. In order to prevent the deformation and dimensional accuracy decline caused by a large amount of shrinkage, the content of solid powder in the material system must be increased to reduce shrinkage [6]. In theory, spherical powder can maximize the loading capacity, but there is another problem that the meshing force between the spheres is very small, and it is difficult to maintain the Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump