Functional ceramic materials refer to materials that mainly use their non-mechanical properties in application. Such materials usually have one or more functions. What are the applications of functional ceramic materials? Next, Pintejin ceramics will introduce to you. Functional ceramic materials refer to materials that mainly use their non-mechanical properties in application. Such materials usually have one or more functions, such as electricity, magnetism, light, heat, chemistry, biology, etc., and some have coupling functions. , such as piezoelectric, piezoelectric, pyroelectric, electro-optic, acousto-optic, magneto-optic, etc. Due to the high development of science and technology, the performance, quality and requirements of ceramic materials are getting higher and higher, which has prompted Read more

Blog

ceramics The shaft is sintered with self-lubricated industrial ceramics, and its advantages are very significant. It is not only wear-resistant but also high-temperature resistant ceramics, so it is often used in motor ceramic shafts. The following Pintejin Ceramic Factory will show you the application of ceramic shafts in ceramic bushings. . Material classification of ceramic shaft and ceramic bushing: alumina ceramic shafts are divided into 2 types: 99% alumina ceramics and 95% alumina ceramics. 99 ceramics are mainly aimed at some small diameter shafts, mainly serving mid-end customers. 95 ceramics are generally aimed at some large diameter shafts. The main service and low-end customers. Zirconia ceramic shaft, mainly for some Read more

Zirconia ceramics is a new type of high-tech ceramics. Zirconia ceramics not only have high strength, high hardness, high temperature resistance, acid and alkali corrosion resistance and high chemical stability, so what are the advantages of zirconia ceramics in all aspects? Next, Pintejin Ceramics will introduce to you. Advantages of zirconia ceramic parts 1. Zirconia ceramic parts have excellent insulation, low high frequency loss and good high frequency insulation. 2. The heat resistance of zirconia ceramic parts has the characteristics of small thermal expansion coefficient, high mechanical strength and good thermal conductivity. 3. Zirconia ceramic parts have the characteristics of chemical corrosion resistance and molten metal properties. 4. Zirconia ceramic Read more

The application of several electronic ceramics has been introduced above, including insulating device ceramics and capacitor ceramics. They are all manufactured with insulating industrial ceramics with low dielectric constant. The following will continue to introduce ferroelectric ceramics and their characteristics. Versatile and versatile. Using its piezoelectric properties, piezoelectric devices can be made, which is the main application of ferroelectric ceramics, so ferroelectric ceramics are often called piezoelectric ceramics. Using the pyroelectric properties of ferroelectric ceramics (the effect of releasing charges on the surface of ferroelectrics due to changes in polarization intensity when temperature changes), infrared detection devices can be made, which can be used in temperature measurement, temperature control, telemetry, Read more

There are many sintering methods for zirconia ceramic rods, such as isostatic pressing sintering, hot pressing sintering, etc. The following Pintejin Ceramics Factory will mainly give a brief introduction to the hot pressing sintering of ceramic rods, and mainly introduce its sintering methods and characteristics. Hot pressing sintering of ceramic rods is a pressure sintering method with unidirectional pressure, and its principle is very simple. Definition of hot pressing sintering: a sintering method in which dry powder is filled into a mold, and then heated while pressing in a uniaxial direction, so that molding and sintering are completed at the same time. The hot-pressing sintering process is simply dry pressing Read more

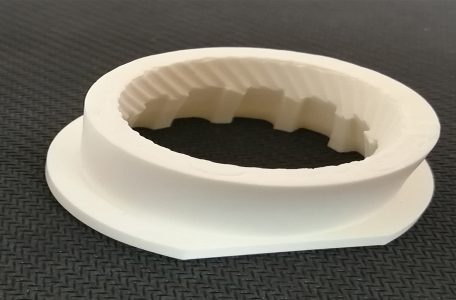

Ceramic HIP sintering technology can produce materials with uniform microstructure, finer and denser grains at lower sintering temperature, and can produce products with complex shapes. So what are the characteristics of HIP sintering for zirconia ceramics? What? Next, Pintejin Ceramics will introduce to you. The hot pressing sintering process for zirconia ceramics can obtain dense ceramic sintered bodies at a lower temperature than pressureless sintering, and the sintering time is much shorter. However, hot pressing sintering adopts unidirectional pressure, so the shape and size of the product are limited by the mold, which is generally cylindrical or annular. In addition, unidirectional pressure also makes the pressure distribution in the green Read more

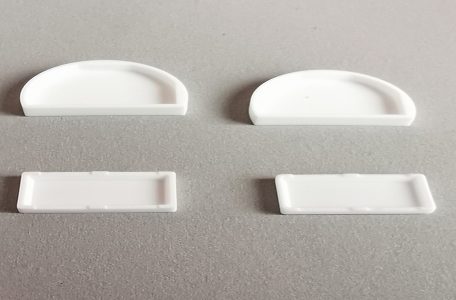

The common thermal conductive ceramic gasket is alumina ceramic material. Because the thermal conductivity of alumina material is very high, it can be used as a thermal conductive and heat dissipation gasket. The following Pintejin ceramic zirconia machining factory will tell you about the thermal conductivity of alumina thermal conductive ceramic gasket. Where is the advantage. Alumina thermal conductive ceramic gasket: high alumina content, relatively dense structure and special properties, so it is called special ceramics. The alumina thermal conductive ceramic gasket material is a close-packed hexagonal structure composed of oxygen ions, and aluminum ions are filled in two-thirds of the octahedral gap, which is the same stable α-Al2O3 structure Read more

Nowadays, the development of new industrial ceramics is very rapid, and their wear resistance is also an important property. Below, Pintejin Ceramics Factory will introduce to you which of the two industrial ceramics, zirconia ceramics and alumina ceramics, has better wear resistance.Zirconia fine ceramic rods Comparison of wear resistance between alumina ceramics and zirconia ceramics: 1. Natural alumina is corundum with a Mohs hardness of 9 and cubic zirconia with a Mohs hardness of 8.5. Therefore, in terms of pure alumina and zirconia, alumina is harder and more wear-resistant. 2. But alumina ceramic is a mixture, it is artificially made by batching and then sintered, not pure brittle corundum. Therefore, Read more

The strength and toughness of single crystal zirconia ceramics are based on its crystal structure. Because of its special crystal structure, it can be made into ceramic parts suitable for various harsh environments. Crystal structure. There are three stable allotropes of zirconia: the monoclinic phase (m), the cubic phase (c), and the tetragonal phase (f)9. The monoclinic phase of pure zirconia is stable from room temperature to 1170 °C, above this temperature it transforms into tetragonal phase, and then transforms into cubic phase at 2370 °C until melting occurs at 2680 °C. There is a hysteresis phenomenon when the ceramic bearing column changes from monoclinic phase to tetragonal phase. Upon Read more

As mentioned earlier, one of the necessary conditions for achieving ceramic sintering is that there should be mass transfer during the sintering process. Under the action of the sintering driving force, only through the material transfer process can the pores be gradually filled, so that the green body becomes dense from loose. At present, the research on the sintering mechanism, that is, the research on the mode and mechanism of material transfer in the sintering process, has four main theories, namely evaporation and condensation, diffusion, viscous flow and plastic flow, dissolution and precipitation. It should be pointed out that the material transfer phenomenon in the actual sintering process is quite Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump