The application of several electronic ceramics has been introduced above, including insulating device ceramics and capacitor ceramics. They are all manufactured with insulating industrial ceramics with low dielectric constant. The following will continue to introduce ferroelectric ceramics and their characteristics.

Versatile and versatile. Using its piezoelectric properties, piezoelectric devices can be made, which is the main application of ferroelectric ceramics, so ferroelectric ceramics are often called piezoelectric ceramics. Using the pyroelectric properties of ferroelectric ceramics (the effect of releasing charges on the surface of ferroelectrics due to changes in polarization intensity when temperature changes), infrared detection devices can be made, which can be used in temperature measurement, temperature control, telemetry, remote sensing and even It has important application value in biology, medicine and other fields. Typical pyroelectric ceramics are lead titanate (PbTiO3).

temperature sensor housing

Using the strong electro-optic effect of transparent ferroelectric ceramic PLZT (lanthanum-doped lead zirconate titanate) (through the control of the electrical domain state of the transparent ferroelectric ceramic by an external electric field to change its optical properties, it exhibits electronically controlled birefringence and electronically controlled light. Scattering effect), can be made into new devices such as laser modulators, optoelectronic displays, optical information memory, optical switches, photoelectric sensors, image storage and displays, and laser or nuclear radiation protection glasses.

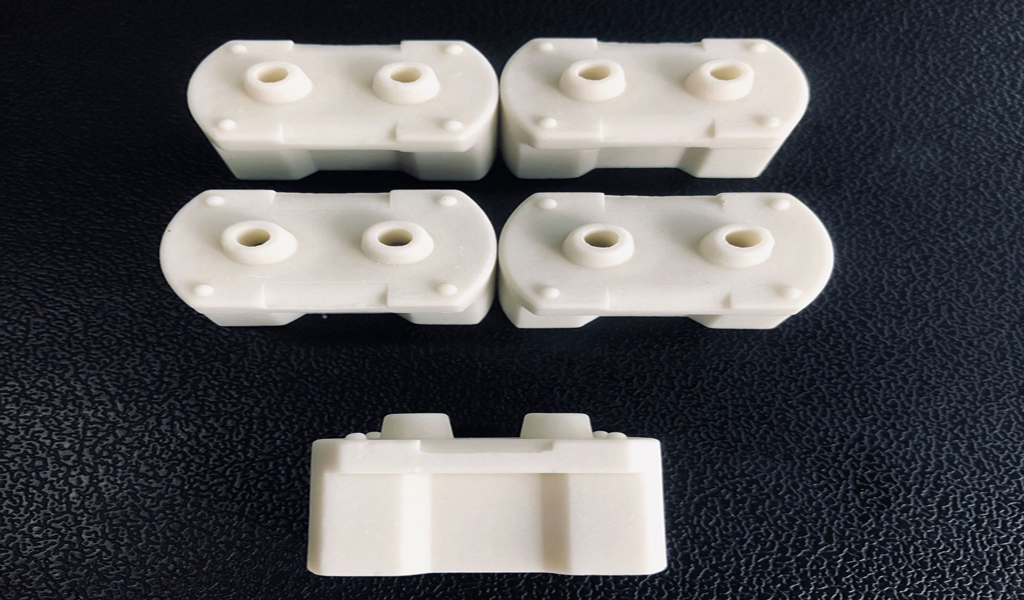

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies