Zirconia ceramic parts are a new type of material in the machinery manufacturing industry. Zirconia ceramic parts have many good characteristics such as high hardness and strong stability. So what are the inspection methods for zirconia ceramic parts? Next, Pintejin ceramics will introduce to you a bit. Zirconia ceramic parts are aliased as structural ceramics, engineering project porcelain, and ceramics. Compared with traditional parts, they have excellent wear and corrosion resistance properties. The production of zirconia ceramic parts requires the production of powder equipment with high purity, good dispersion characteristics, fine particles and narrow particle size analysis. There are many ways to prepare zirconia ultrafine powder. The purification of zirconia Read more

Blog

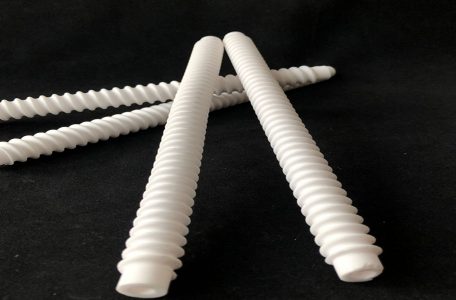

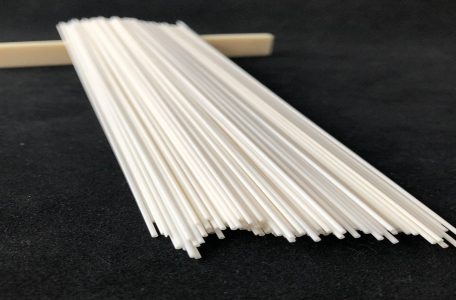

Ceramic rods are generally made of highly wear-resistant zirconia ceramics and alumina ceramics. So what are the specific characteristics of these wear-resistant ceramic rods? The following Pintejin Ceramics Factory will tell you about it. The performance characteristics of wear-resistant ceramic rods are: High hardness: Its Rockwell hardness is HRA80-90, which is only slightly lower than that of diamond, but compared with wear-resistant steel and stainless steel, the hardness is far beyond the two. Good wear resistance: it can prolong the life of the equipment, up to ten times more. Wear-resistant ceramic rods Light weight: The weight is only the average of steel, which can greatly reduce the load on the Read more

Alumina ceramics is the most common ceramic material in many industrial ceramics. It has many characteristics and properties and can be used in all walks of life. The following Pintejin Ceramics Factory will introduce the most significant characteristics of alumina ceramics. 1. Alumina ceramics have good high temperature resistance characteristics, and are a kind of high temperature resistant ceramics with very high mechanical strength and very good conductivity. However, it should be noted that when washing the ceramic, it should be washed with ultrasonic waves, and other items should not be used for cleaning, because it is a very special material. Alumina wear-resistant ceramic plate 2. Very light weight. The Read more

With the continuous development and progress of science and technology, alumina ceramic sheets with superior performance have been widely used in various fields. So what are the advantages and disadvantages of alumina ceramic sheets and how to identify them? Next, Pintejin ceramics will introduce to you. First of all, we will introduce alumina ceramic sheets. Alumina ceramic sheets are also called wear-resistant alumina ceramic linings, high-alumina linings, wear-resistant ceramic linings, alumina ceramic patches. Alumina ceramic sheets are mainly made of AL2O3 as raw materials. It is calcined at a high temperature of 1700 ℃ with rare metal oxides as a solvent. Because of its relatively dense structure and special properties, Read more

Alumina ceramics are the most widely used in the entire ceramic industry, so their performance is also very superior. The use of alumina ceramics in modern society is gradually increasing. Alumina ceramics that can meet various special performance requirements mainly have the following three advantages. 1. High hardness of alumina ceramics The Rockwell hardness of alumina ceramics tested by a third-party professional organization can reach HRA80-90 hardness, second only to diamond. 2. Alumina ceramics have good wear resistance The wear resistance of alumina ceramics exceeds that of manganese steel by more than 266 times and that of high-chromium cast iron by more than 171.5 times. According to the follow-up survey Read more

The preparation of alumina ceramics by casting method was studied, and the effects of powder characteristics and casting parameters on the structure and performance of ceramics were discussed. The impurity content of alumina ceramic raw materials, crystallization tracing, α·phase conversion rate, particle size distribution, etc. have influence on the casting process and the quality of ceramic plates, and the performance index of alumina raw materials for ceramic plates by combined casting method is proposed. It can be seen from the comparison of the heavy ceramic heat dissipation substrate that although the thermal conductivity of the al2o3 material is about 20~51 (w/mk), ltcc adds 30%~50% glass to reduce the sintering temperature. Read more

There are many methods for forming alumina ceramics, such as dry pressing, grouting, extrusion, cold isostatic pressing, injection, casting, hot pressing and hot isostatic pressing. So what are the treatments that need to be done after forming alumina ceramics What? Next, Pintejin Ceramics will introduce to you. 1. Dry grinding In the process of preparing alumina ceramics, it is necessary to use sandpaper to polish the alumina ceramics. Usually, this bile film is more suitable for the hard and brittle paint.A certain amount of dust will be generated during the grinding process, so the preparation staff of Dongguan alumina ceramics should pay attention to avoid inhalation. 2. Wet Read more

What is the basic principle of the way to semiconductorize functional ceramics? What are the factors that affect semiconductorization? The way to semiconductor: 1. Donor doping semiconducting, generally high-valent doping La3+, Y3+, Sb3+, Nb5+, Ta5+Fundamental: 2. Forced reduction semiconductorization. Basic principle: Factors affecting semiconductorization: (1) Influence of additives and impurities. If the concentration is too large or too small, the resistivity will increase and an insulator will be formed. (2) The influence of deviation of stoichiometric ratio. 3. The influence of firing conditions. The influence of firing temperature and holding time is greater.

There are many ways to process structural ceramics. According to different machining requirements, the following are the common methods of structural ceramics machining by Pintejin zirconia ceramic machining manufacturers. Structural ceramic machining surface grinding There are many methods for structural ceramic machining surface machining, basically all machining methods can process plane, turning, milling, planing, grinding, drawing, wire cutting. Among them, it is most used in surface grinders. Grinding is generally used for finishing. Planing and wire cutting are generally used when batches are very small. The surface roughness of structural ceramics is that after the ceramic parts are formed and sintered, there will be many uneven peaks and valleys on Read more

Ceramic rods usually use wear-resistant zirconia ceramics or alumina ceramics as raw materials, which have excellent performance, but some factors will affect the use of ceramic rods. Pintejin Ceramics Factory will tell you what factors will affect ceramic rods? Influence of raw material powder: The main raw material of ceramic rod is high-purity zirconia powder, and its performance and content have a great influence on zirconia ceramics. In the preparation process of ceramic powder, it is inevitable to introduce impurities. The organic impurities are burned off during the firing process, and irregular pores are formed in the process of early densification. Inorganic impurities may react with the ceramic powder at Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump