Zirconia ceramic materials can be processed into many structural ceramics, which replace traditional metal materials in many aspects. Below, Pintejin Ceramics Factory will tell you the difference between zirconia ceramic injection pumps and metal pumps. The difference between ceramic injection pump and metal pump: Ceramic injection pumps have developed by leaps and bounds in recent years, and most of the plunger pump industry uses metal plunger pumps. Although the metal plunger pump has been improved in structure and material, it is limited by the properties of metal materials and cannot meet the needs of increasingly high wear, strong corrosion and other harsh working conditions. It is mainly reflected in the Read more

Ceramic jars are made of new ceramics for industrial ceramics. Pintejin Ceramics is a manufacturer specializing in the production and machining of zirconia ceramics. Below, Pintejin Ceramics will introduce you to industrial ceramic jars. Ceramic grinding jars Our common ceramic jars are made of pottery clay, made into a round belly, coated with black or yellow glaze, and fired in a kiln to hold or cook food. Ceramic jar is a modern new type of jar, which is made of industrial ceramic materials. There are covered and uncovered, with various forms and uses. Pintejin Ceramics can produce ceramic parts and structural parts of various shapes and sizes according to customer Read more

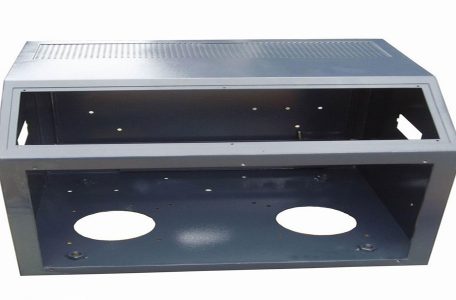

With the rapid development of my country’s industrial field, traditional metal materials cannot meet our performance requirements, while ceramic materials have a variety of excellent properties and are widely used in industrial fields. Now Pintejin Ceramic Zirconia Processing Factory will tell you about industrial ceramic parts. Industrial ceramic parts positioning pins Because industrial ceramic parts have a series of advantages such as high temperature resistance, corrosion resistance, wear resistance, erosion resistance, etc., they can replace metal materials and organic polymer materials in harsh working environments, and have become traditional industrial transformation, emerging industries and high-tech. It is an indispensable and important material in energy, aerospace, machinery, automobile, electronics, chemical industry Read more

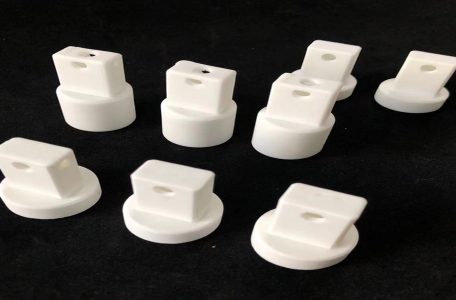

Industrial ceramics will have many characteristics and advantages after being used to make ceramic plungers, including its use and performance. Pintejin Ceramics Factory will give a brief introduction to industrial ceramic plungers. The ceramic plunger adopts modern engineering ceramic material with super hard wear resistance, and can be assembled and formed by ceramic metallization bonding, welding, inlay and socket technology. It is an ideal substitute for similar metal pumps, and has been widely used in medical equipment, environmental engineering, petroleum, chemical and other industries. Ceramic plunger Industrial ceramic plunger has the following characteristics: (1) The ceramic plunger adopts high-performance technical ceramic material, which has the properties of high hardness, wear Read more

Recently, some people have raised the issue that zirconia ceramics will crack after sintering, so what is the truth? Below is the answer from Pintejin Ceramics. The pure zirconia ceramics were sintered and cracked. The zirconia made by the grouting method was naturally air-dried for 3 days and then placed in a high-temperature furnace. The temperature was raised to 1450°C at 3°C/min and 5°C/min respectively, held for 4 hours, and cooled out of the furnace. Cracking occurs. Due to the high hardness of stabilized zirconia, it is generally used in a steel ball mill for ductile ink, pickling after the ductile ink, and then neutralized with water and dried. Using Read more

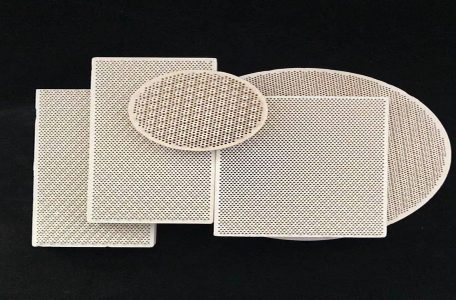

Industrial ceramics are widely used due to their high wear resistance, high hardness, and especially excellent insulating properties. Insulating porcelain, also known as device porcelain, is widely used in electrical equipment. Commonly used products are: high-frequency insulators, sockets, porcelain shafts, porcelain tubes, substrates, band switches, etc. Zirconia Industrial Ceramic Parts The basic requirements for insulating porcelain are low dielectric constant ε, small dielectric loss tanδ, high insulation resistivity ρ, high breakdown strength E, and good dielectric temperature characteristics and frequency characteristics. In addition, high mechanical strength and chemical stability are also required. Insulation porcelain mainly refers to porcelain products used for installation, fixation, support, protection, insulation, isolation and connection of Read more

Fine ceramics is a kind of industrial ceramics that uses highly selected high-purity chemical products as raw materials, and is used in industry. Fine ceramics include zirconia ceramics, silicon nitride ceramics, etc., which are very different from traditional ceramics. Let Pintejin ceramics introduce you to the main differences between the two.Fine ceramic parts The main differences between fine ceramics and traditional ceramics: 1. In terms of raw materials, it breaks through the boundaries of traditional ceramics with clay as the main raw material. Special ceramics generally use oxides, nitrides, silicides, borides, carbides, etc. as the main raw materials. The main difference is that the various chemical composition, morphology, particle size Read more

Zirconia Reaction Sintering Mode Zirconia ceramics can be used in various fields due to their unique properties, but there are problems such as high preparation cost and difficulty in preparing large-sized special-shaped components. Drawing on the experience of preparing reactive sintered alumina ceramics, the Al and AIN powders were fully mixed, then formed by cold isostatic pressing and reacted in a zirconium gas atmosphere. The newly generated Al particles after zirconization of the Al powder are nanoparticles, and the “old” Al particles are combined during the sintering process to obtain reaction-bonded aluminum anchor (RBA) ceramics. Since Al zirconium is accompanied by a quantitative volume expansion, it can partially offset the Read more

The crystal structure of zirconia ceramics is the basis of its wear resistance and high temperature resistance. When zirconia ceramics have a special crystal structure, it has a series of excellent characteristics. Then what is its crystal structure? Introduce everyone. The materials of zirconia ceramics and zirconia toughened alumina ceramics are widely used. Due to the excellent physical and chemical properties of zirconia, it has a prominent position in engineering ceramics and advanced ceramics, such as ceramic rods, piston crowns of ceramic engines. and many more. There are three stable allotropes of zirconia: monoclinic, cubic and tetragonal. The monoclinic phase of pure zirconia is stable from room temperature to 1170°C, Read more

There are many places where alumina ceramics are used, and alumina ceramics are also damaged during use. What are the reasons for the damage to alumina ceramics? Next, Pintejin ceramics will introduce to you. 1. External force A major factor for the wear of alumina ceramics is the strong external force, which is generally caused by impact force and pressure during operation.Due to the strong external force, it is worn or broken, which is unfavorable for alumina ceramics. We should try our best to avoid collision with objects during operation to minimize damage. 2.The influence of the external environment General environmental factors include the influence of the medium in Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump