New ceramic materials have their unique advantages in performance and are widely used in the field of modern science. The following Pintejin zirconia ceramic machining manufacturers will introduce the classification and performance of new ceramic materials to you. In terms of thermal and mechanical properties, the new ceramic materials have high temperature resistance, heat insulation, high hardness, wear resistance, etc.; in terms of electrical properties, they have insulation, piezoelectricity, semiconductor properties, magnetic properties, etc.; in terms of chemical properties It has the functions of catalysis, corrosion resistance and adsorption; in terms of biology, it has certain biocompatible properties and can be used as biological structural materials. But it also has Read more

Blog

Ceramic materials are typical hard and brittle materials. Before the mid-to-late 20th century, people thought that zirconia ceramic materials could not be processed or could not be processed, so they could only be processed into the desired shape when making green bodies, and then used directly after firing. The reason for removing the hard and brittle characteristics of the ceramic material itself is mainly due to the lack of machining tools and machining methods at that time. Although people have discovered superhard materials such as diamond and vertical boron nitride that are much harder than ceramic materials, the machining of ceramic materials has only been developed in recent decades. The Read more

At present, the main raw material for the production of special alumina products is industrial alumina, which is an intermediate product of the aluminum smelting industry. Its true density is 3.60g·cm-3, and its mineral composition is γ-Al2O3. Industrial alumina is white powdery material. The chemical composition of general products is shown in the table. When manufacturing special pure products, raw materials with Al2O3 content greater than 99.8% or raw materials prepared from aluminum sulfate and ammonium sulfate should be used. Industrial alumina is difficult to sinter. In order to improve the sintering temperature, the raw materials need to be finely pulverized and pre-sintered, and additives that promote sintering are added. Read more

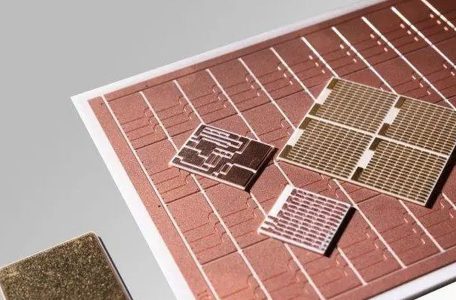

In the realm of modern electronics, where precision and efficiency reign supreme, the quest for superior materials and manufacturing techniques is unending. Among the myriad of components that constitute the backbone of electronic devices, printed circuit boards (PCBs) stand as fundamental pillars. These intricate platforms serve as the very foundation upon which electronic circuits are built, enabling the seamless flow of electrical signals. In this pursuit of excellence, one innovation has emerged as a cornerstone in the domain of PCB fabrication: the Alumina Multi-Layered Board by Etching. The Alumina Multi-Layered Board (AMLB) represents a pinnacle of engineering ingenuity, combining the remarkable properties of alumina with the intricacy of multi-layered design. Read more

Performance of zirconia ceramics: pure ZrO2 is white, yellow or gray when it contains impurities, and generally contains HfO2. Zirconia ceramics are a new type of ceramics. Because of their excellent physical and chemical properties, zirconia ceramics have not only become a research hotspot in the field of scientific research, but also have been widely used in industrial production. Zirconia ceramics have the best high-temperature thermal stability and thermal insulation performance, and are suitable for ceramic coatings and high-temperature parts. The thermal conductivity of zirconia ceramics is the lowest among common ceramic materials, and the thermal expansion coefficient is relatively close to metal materials. It is an important structural ceramic Read more

What industries are ceramic parts generally used in? Our ceramic parts can be divided into ordinary ceramic parts and precision ceramic parts. In which industries are these ceramic parts generally used? Next, Pintejin Ceramics, a manufacturer specializing in the production of zirconia ceramics and alumina ceramics, will tell you which industries the key ceramic parts are generally used in. Alumina ceramic parts Which industries are ceramic parts generally used in: Ceramic parts mainly refer to those mainly used in chemical plants for filtration and purification, as well as for grinding materials. Building-sanitary ceramics: such as bricks and tiles, drainage pipes, face bricks, exterior wall tiles, sanitary ware, etc.; Chemical (chemical) Read more

In recent years, my country’s industrial ceramics have developed rapidly, and it has become a large cross-industry and interdisciplinary industry. The output value of the national industrial ceramics has accounted for more than half of the ceramic industry, and it has a very important strategic position in the entire national economy. Experts predict that the market demand for industrial ceramic products in China will grow at an average annual rate of about 8.5%. Industrial ceramic technology is an important part of the application field of science and technology. Most high-tech development is inseparable from high-tech industrial ceramics, and the development of high-tech industrial ceramics also requires high-tech support. Facing the Read more

With the development of science and technology, the quality requirements of zirconia toughened alumina products are higher and better, so the products have certain friction during preparation, which is what we call friction theory. The following will introduce the friction theory in detail: 1. Zirconia toughened alumina adhesion theory: The adhesion theory of zirconia toughened alumina believes that under a certain pressure, when zirconia toughened alumina is dry rubbed, it will generate instantaneous high temperature, sometimes even more than 1000e, which will cause zirconia toughened alumina to produce a certain degree of damage. Plastic deformation, the two objects will stick together. Its friction is a pulsating process in which sticking Read more

The production of ceramic products has a long history in China. After a long period of development, the manufacturing process has been continuously developed. Especially in the past two decades, the reasonable adjustment of the structure of zirconia ceramic products has catered to the consumer demand of consumers at home and abroad, and with the development of society and the improvement of living standards, the application range in life has become wider and wider. At the same time, my country’s total export trade of ceramic products is making every effort to increase. The export of daily-use ceramics, architectural ceramics, sanitary ceramics and zirconia ceramics has shown a gratifying scene of Read more

Special ceramics, also known as fine ceramics, are classified according to their application functions and can be roughly divided into two categories: high-strength, high-temperature-resistant and composite structural ceramics and electrical and electronic functional ceramics. Inorganic materials with special formula are added to the ceramic blanks, which are sintered at a high temperature of about 1360 degrees to obtain stable and reliable anti-static properties and become a new type of special ceramics, which usually have one or more functions, such as: electricity, magnetism, Optical, thermal, acoustic, chemical, biological and other functions; and coupling functions, such as piezoelectric, pyroelectric, electro-optical, acousto-optical, magneto-optical and other functions. At present, special ceramics have been widely Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump