Cermets are composite materials composed of one or more ceramic phases and metal phases or alloys. Ceramic phase generally refers to high melting point oxides (alumina, beryllium oxide, magnesium oxide, zirconium oxide, etc.) and refractory compounds (titanium carbide, tungsten carbide, tantalum carbide, boron carbide, zirconium diboride, titanium diboride and Tantalum diboride, etc.). The metallic phases are mainly transition elements (iron, cobalt, nickel, chromium, molybdenum, tungsten, vanadium, niobium, tantalum, etc.) or their alloys. The ceramic phase accounts for about 15% to 85% of the volume. Cermet not only has the advantages of metal toughness, high thermal conductivity and good thermal stability, but also has the characteristics of high temperature resistance, corrosion Read more

Blog

After the alumina ceramic is sintered and cooled, it does not mean the end of product machining. Some products still do not meet the application requirements, so they need to be processed, such as size correction, polishing, etc. In order to give everyone a clearer understanding, the technical staff of alumina ceramics manufacturers, today will introduce in detail, what are the polishing treatment methods of alumina ceramics? 1. Grinding and polishing by laser machining and ultrasonic machining. 2. Use Al2O3 powder or diamond paste for grinding and polishing. 3. Glazing method is required (suitable for products that require high surface smoothness). 4. Grind from coarse to fine with diamond, silicon Read more

Ceramic wear-resistant pipes, as the name suggests, are pipes made of ceramics. In life, pipes are very common in buildings and construction sites. Tubular objects are everywhere. As shown in the figure: Zirconia ceramic tube But ceramic wear-resistant tube is different from other tubes. Let’s take you into the world of ceramic wear-resistant tube by Pintejin! The full name of ceramic wear-resistant pipe is corundum ceramic lined wear-resistant composite pipe, which is a kind of ceramic composite steel pipe. It is manufactured by high-tech production process – self-propagating high-temperature clutch synthesis method. The ceramic wear-resistant pipe is composed of three layers of corundum ceramic, transition layer and steel. Because the Read more

The zirconia ceramic plunger is made of ceramic as a whole, but only part of the surface of the sprayed ceramic plunger is made of zirconia ceramics, so the performance characteristics of the two are still different. Pintejin Ceramics Factory will analyze it for you below. The high-pressure plunger pump is the core component of the high-pressure cleaner, and the plunger is the most easily worn core component in the movement, and its quality will directly affect the performance of the whole machine. According to the different materials of the plunger, the plunger can be summarized into three types: metal plunger, ceramic plunger, and porcelain-sprayed plunger. At present, the plungers Read more

my country’s national standard GB3500-83 is basically the same as the first definition, which is defined as “a sintered material consisting of at least one metallic phase and at least one non-metallic phase usually of ceramic properties”. According to this definition, dispersion-strengthened materials, sintered friction materials, and electrical contact materials containing graphite or oxides and carbides all belong to cermets. For cermets, the main issue to consider is how to combine two or more different phases to obtain a good microstructure. For this purpose the metal (alloy) phase and the ceramic phase must take into account the following conditions:There should be a certain solubility between the metal phase and the Read more

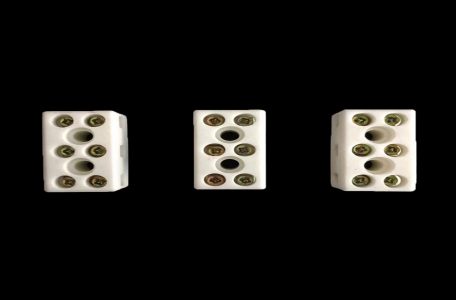

Electronic ceramics are usually made of alumina ceramics with low dielectric constant. Below, Pintejin Ceramics Factory will introduce capacitor ceramics to you. Different ceramic components have different dielectric constants, so the obtained capacitor ceramics are not nearly the same. Low frequency ceramics with semiconductor capacitors. Electronic ceramics used as capacitor dielectrics. This type of ceramics is used in a large amount and has many specifications and varieties. The main ones are high frequency, low frequency capacitor porcelain and semiconductor capacitor porcelain. High-frequency capacitor porcelain, belonging to class I capacitor porcelain, is mainly used to manufacture high-stability ceramic capacitors and temperature compensation capacitors in high-frequency circuits. The main components of such Read more

Although zirconia ceramics have many excellent characteristics, there are still many problems in the use of dispensing ceramics made of them. To sum up, there are 8 points. The following Pintejin Ceramics Factory will analyze it for you. 1. Ceramic dispensing valve dripping This situation often occurs after the dispense valve is closed. 95% of these cases are due to the use of needles that are too small in diameter. A needle that is too small can interfere with the flow of fluid and cause back pressure, which can result in dripping shortly after the valve is closed. A needle that is too small can also interfere with the valve’s Read more

Alumina ceramics is a material with alumina (AL2O3) as the main body, which has high strength, high hardness, corrosion resistance and good insulation. And it is a kind of high temperature resistant ceramics. Below Pintejin Ceramics Factory will introduce the process temperature in the production process of alumina ceramics. The operating ambient temperature of alumina ceramics mainly refers to the maximum process temperature used in the production process of alumina ceramics. In a production process, the higher the temperature used, the higher the relative manufacturing cost and the higher the yield. Not easy to control. The process temperature of the ceramic HTCC process itself is about 1300~1600℃ due to the Read more

Compared with metal materials, the machining performance of zirconia ceramics is obviously reduced a lot, because of its brittleness, but it is a high temperature resistant ceramics and has super wear resistance and corrosion resistance, high hardness and high strength, the following Pintejin Ceramics Factory How to solve the toughening method of ceramic matrix composites will be introduced. Since ceramics are polycrystalline sintered materials composed of ionic bonds or covalent bond grains, there is almost no slip or dislocation movement at room temperature. Once the material is in a stressed state, it is difficult to cause slip or dislocation. Plastic deformation is used to relax stress, and the energy required Read more

With the development of science and technology, more and more daily necessities have become intelligent, among which electronic ceramic parts play a great role. What will be the research direction of electronic ceramics in the future? The following Pintejin Ceramics Factory will conduct a brief analysis of its research and development. Electronic ceramics refer to ceramics that can utilize electrical and magnetic properties in the electronics industry. Electronic ceramics are ceramics with new functions that are finally obtained through precise control of the surface, grain boundaries and dimensional structure. It can be widely used in energy, household appliances, automobiles, etc. The research directions of electronic ceramics are: ① Study the Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

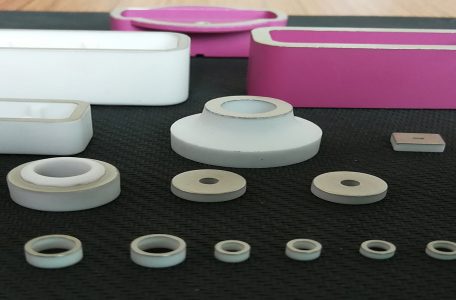

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

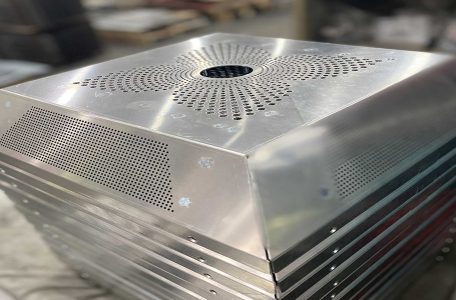

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump