With the continuous development and progress of science and technology, Dongguan industrial ceramic products with superior performance have been widely recognized by the society. Do you have any precautions when using functional ceramic rods? The following is a professional manufacturer of zirconia ceramics, alumina ceramics and other functional ceramics to introduce the three points of attention for the use of industrial ceramic rods. Precautions for the use of industrial zirconia ceramic rods Dongguan functional wear-resistant ceramic rods: 1. The surface temperature should not be too high. Even very durable wear-resistant ceramic rods need to pay attention to the temperature of the use environment, because its life will be affected by Read more

Blog

Silicon carbide ceramics outperform other ceramic spare parts in certain industrial applications. There are many ceramic spare parts in the market, such as alumina ceramic parts, zirconia ceramic parts, silicon carbide ceramic parts. The following is a detailed introduction to the use and characteristics of silicon carbide ceramics by Pintejin ceramic manufacturers. Silicon carbide ceramic ring In air, silicon carbide begins to oxidize at 800°C, but very slowly. The oxidation rate increases rapidly with increasing temperature. Silicon carbide oxidizes 1.6 times faster in oxygen than in air and slows down with time. A typical parabolic profile can be obtained if quantitative oxidation traces occur over time, which reflects the effect Read more

Special ceramics include zirconia ceramics and alumina ceramics. Their mechanical properties are particularly superior, so they can be processed into auto parts. Below, Pintejin Ceramics Factory will introduce the application of special ceramics in auto parts. . 1.The application of ceramics in automobile engines The new ceramics are sintered from inorganic non-metals such as silicon carbide and silicon nitride. Compared with the alumina ceramics used in the past, the strength is more than three times that of it, and it can withstand high temperatures above 1000 degrees Celsius. The new material promotes the development of new applications in automobiles. For example, to reduce the fuel consumption of diesel engines by Read more

The sol-gel method is a method of converting a sol with a concentrated metal oxide or hydroxide into a gel, and then drying the gel and then calcining it to obtain an oxide. The sol of ceramic powder will be further elaborated by Pintejin ceramic manufacturer below. The sol of ceramic powder first causes fine particles to be suspended in an aqueous solution (sol), and then drops the sol into a dehydrating solvent to make the particles agglomerate into a colloid (ie gel), and then remove the solvent or allow the solute to precipitate. turns into a gel. The pH value of the solution, the ionic or molecular concentration of Read more

In recent years, many scholars have applied the diamond grinding method to systematically study the theory and process of plastic grinding of brittle materials of zirconia ceramics, brittle-plastic transition, material properties, cutting force and other parameters. Plastic way surface formation mechanism and geometric accuracy of zirconium ceramic parts, including research and development of related machine tool and grinding wheel technology. 1. Machining of zirconia ceramics: The machining of zirconia ceramic materials is not only suitable for semi-sintered body ceramics, but also for fully sintered body zirconia ceramics. The cutting process of semi-sintered zirconia ceramics is to reduce the machining allowance of fully sintered body ceramics as much as possible, thereby Read more

Grinding usually refers to the use of micron-scale abrasive particles with a hardness that is farther away from the material to be processed, and the micro-cutting and rolling action generated by the hard grinding disc to achieve the removal of trace materials on the machined surface, so that the shape and size of the workpiece are accurate. Reach the required value, reduce the surface roughness, and reduce the machining method of machining the metamorphic layer. 1. Grinding Mechanism Advanced ceramic materials are hard and brittle materials that are difficult to machine. In the grinding process of such materials, the material to be processed is removed by the rolling action or Read more

Compared with metal plungers, the ceramic plunger for pump has many advantages and is an ideal substitute. The ceramic plunger for pump has the properties of corrosion resistance, high temperature resistance and wear resistance. The following Pintejin zirconia ceramic machining manufacturer will tell you about the pump Advantages of using ceramic plungers over metal plungers. Advantages of ceramic plunger for pump Ceramic plunger for pump: 1. More reliable performance Because the production process of ceramic plunger for pump is advanced and the ceramic material itself has very good corrosion resistance, it can be produced by advanced technology.Through the safety performance test of corrosion resistance, acid and alkali resistance, etc. Therefore, Read more

Pintejin Ceramics Factory took you to understand what Aluminum Nitride Ceramic sheets are. I don’t know if you are clear about it. Next, let us understand what are the advantages of aluminum nitride ceramic sheets? Advantages of aluminum nitride ceramic sheets: 1. Aluminum nitride powder has high purity, small particle size and high activity. It is the main raw material for manufacturing high thermal conductivity aluminum nitride ceramic substrates. 2. Aluminum nitride ceramic substrate, high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity, low dielectric loss, is an ideal large-scale integrated circuit heat dissipation substrate and packaging material. 3. The aluminum nitride ceramic Read more

The compressive strength and flexural strength of zirconia ceramics are relatively strong, and their mechanical properties are also strong. Many scientific research laboratories use zirconia ceramics as experimental materials, so what aspects of its mechanical properties are reflected? The following Pintejin Ceramics Factory will give you a brief analysis. Now it can be seen that ceramics are very popular in the international market. It can be clearly seen that industrial ceramics manufacturers have modern management beliefs, advanced ceramic machining technology, and have very strong advantages. 1. Wear resistance: The Al2O3 content in the lining ceramic layer of the ceramic composite steel pipe is more than 90%, and the microhardness is Read more

High-efficiency and high-precision machining method for zirconia ceramic materials 1. ELID superfinishing ELID is the abbreviation of Electrolytic Online Dressing Grinding Method. It applies a grinding wheel composed of metal bond and super-hard micro-diamond (or CBN) abrasive, and at the same time electrolytically sharpens the grinding wheel during the grinding process, so that the grinding wheel is always kept sharp, thus ensuring ultra-precision grinding under high efficiency conditions Therefore, it is an advanced method for mirror grinding of brittle materials (such as ceramics, glass, silicon and iron oxide, etc.). The high material removal rate grinding of zirconia ceramic materials by ELID method can greatly reduce the grinding cost. When reasonable Read more

Ceramic Machining Industry

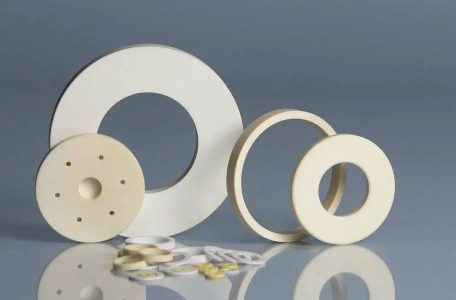

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump