Ceramic Injection Molding

What Is Ceramic Injection Molding

Ceramic injection molding (CIM for short) is a branch of modern powder injection molding (PIM) technology. Ceramic injection molding (CIM) is a technology of net size molding.

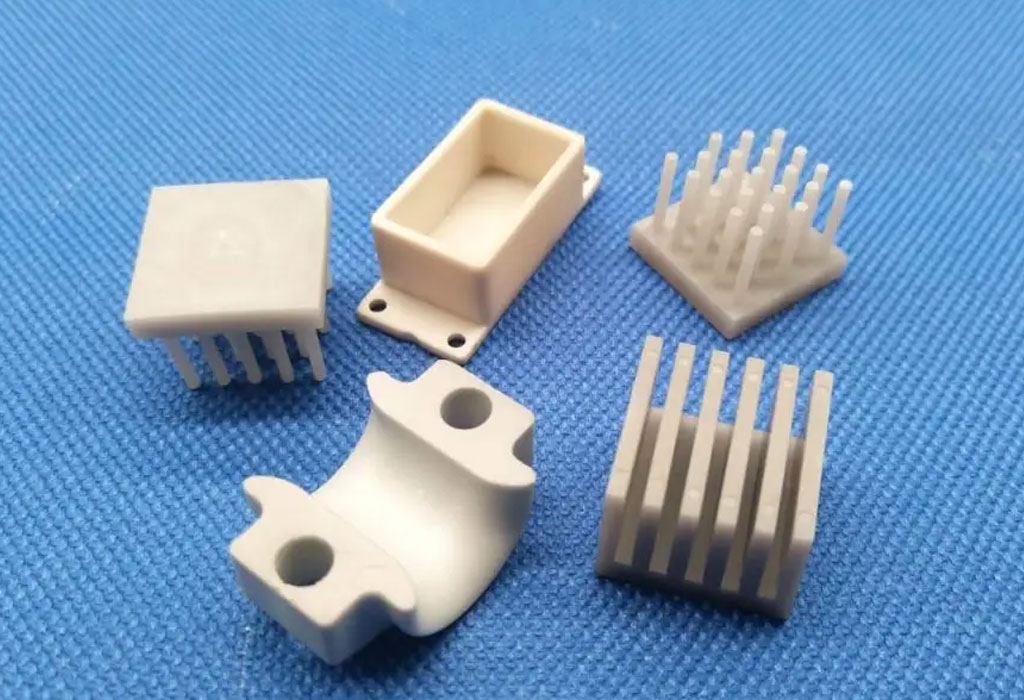

It is especially suitable for ceramic structures with small volume, complex shape and high precision. It has many special technical and process advantages:

- It can be mass-produced quickly and automatically, and its process can be accurately carried out. control; due to flow filling, the density of the green body is uniform;

- Due to high pressure injection, the powder content in the mixture is greatly increased, the shrinkage of the sintered product is reduced, and the product size is precisely and controllable, with a tolerance of ±0.1%~0.2%, performance Superior;

- Ceramic special-shaped parts with transverse holes, oblique holes, concave and convex surfaces, threads, thin walls and difficult to be machined can be formed without machining or only micro-machining, reducing the preparation cost and reducing the preparation cost, and have a wide range of application prospects.

Because it can produce complex shape products, high dimensional accuracy, less machining, smooth surface, suitable for mass production and low cost, it has become the fastest growing and most widely used precision manufacturing technology for ceramic parts in the world. Ceramic preparation technology is especially widely used in the production of alumina ceramics.

Ceramic injection molding (CIM) is a new type of ceramic molding technology, and its basic process can be divided into 4 stages: feed preparation, injection molding, degreasing and sintering”.

Compared with traditional dry pressing molding technology, CIM has the following advantages:

- The molding process has a high degree of automation, and can mass-produce ceramic parts with complex shapes, high dimensional accuracy and small volume;

- The formed ceramic green body has a compact structure, uniform mass distribution, and the final sintered performance is also better than that of traditional molding;

- CIM is a near-size molding process. The products produced have extremely high dimensional accuracy and surface finish. No (or only a small amount of) subsequent processing is required, which greatly reduces the production cost. In the traditional molding process, the later size Precision machining accounts for about 30% of the entire ceramic preparation cost.

Therefore, the CIM molding process is currently the most popular precision ceramic molding process, which has been widely used in the fields of vehicle machinery, aerospace, energy communication and medical equipment.

Ceramic Injection Molding – Ceramic Mold Making Services

Need ceramic injection molding manufacturer for mass production parts? Pintejin is known as the best mold maker in China. With mold making facilities in house and resources from our partners, we are able to provide injection molds for zirconia, alumina, silicon ni- tride, silicon carbide, aluminum nitride, microporous ceramics for all type of precision industry ceramic parts, and powder metallurgy molds for ceramic. We offer low-cost local production injection molding ceramic parts and high-quality exported molds for all your project needs.

Whatever you need prototype molds for the short-run production, or mass production ceramic injection molding molds for millions shots,Pintejin can handle them for you smoothly.

Our Advantages of Ceramic Injection Mold Making Services

Pintejin is an experienced provider of ceramic injection mold making services with lots to offer beyond our competitors:

1. Fast DFM reports

Although we check your design feasibility when providing a quote, we can provide a fast and thorough DFM (design for manufacturability) report before production begins. In the DFM report, we’ll identify any errors or issues that might cause a manufacturing problem down the line.

2. Wide range of molds

We offer several different types of molds, which means you can avoid splitting your projects; just send everything to us to ensure your project runs smoothly.

3. Fast Turnaround

Our large facility and machining capabilities allow us to build molds quickly, whatever the application or material, which means you can get your moldings completed faster.

4. Injection Molding Capabilities

Pintejin can ship your molds to you directly, but we can also handle injection molding and other production services to deliver you prototypes and final parts using those molds.

Ceramic Injection Molding Molds Making FAQ

The Related Guide Of Ceramic Injection Molding

Ceramic injection molding (CIM), as an emerging precision ceramic molding technology, has incomparable advantages compared with traditional ceramic molding processes. In the past few decades, it has developed rapidly and has become the most popular molding technology in the industrial production of precision ceramics. However, CIM also has certain problems: higher requirements for powder, more complicated molding process, and difficulty in removing organic binders. In the future, the focus of CIM technology research should be on powder preparation technology, new binder development and new degreasing technology, so CIM technology will play a more important role in aerospace, industry, national defense, civil, medical and other fields.

Currently, our CIM Ceramic parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom ceramic injection molding and molds fabrication service provides durable and affordable ceramic parts that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your ceramic injection molding and ceramic molds project.

The Define And Process Of Ceramic Injection Molding

Injection molding refers to a model with a certain shape, which is formed by injecting the melted colloid into the mold cavity by pressure. The pressure is about 120 tons. The process principle is: first mix the powder with polyethylene, paraffin and stearic acid through a kneader. Together, they are melted according to a certain melting point, injected into the mold at a certain speed through the pressure of the injection machine, and the mold is cooled by the water channel to solidify the powder to obtain the same product as the designed cavity.

1. Process Flow

The complete injection process includes:

- The powder is mixed with polyethylene, paraffin and stearic acid by a kneader

- Injection process

- Bubble oil

- Glue removal

- Sintering

2.The Specific Process Of Molding

- Preparation before molding: In order to make injection molding go smoothly and ensure product quality, a series of preparations such as raw material pretreatment, barrel cleaning, preheating of inserts and selection of release agent are required before production.

- Injection process: The injection process generally includes: feeding – molding – demoulding – oil foaming – degumming.

- Injection molding feeding: Since injection molding is an intermittent process, quantitative (constant volume) feeding is required to ensure stable operation, uniform force on the powder, and high-quality ceramic parts.

- Injection molding plasticization: The molding material is heated, compacted and mixed in the barrel of the injection machine, and is transformed from a loose powder or granular solid into a continuous homogenized melt.

- Injection molding injection: The plunger or screw starts from the metering position in the barrel, and high pressure is applied through the injection cylinder and piston to quickly feed the plasticized plastic melt through the nozzle at the front of the barrel and the gating system in the mold The process of closing the mold cavity. Injection can be subdivided into three stages: flow filling, pressure-holding feeding, and backflow.

- Injection molding demoulding: The ceramic part can be opened after cooling to a certain temperature, and the ceramic part can be pushed out of the mold under the action of the push-out mechanism.

3. Post-Processing Of Molding

- Bubble oil: remove wax to ensure material purity.

- Glue removal: The function is to discharge the organic binders and glues as admixtures, so as to ensure the shape, size and quality of the product.

- Both degumming and foaming have a great influence on the quality of ceramic products.

4.The Advantages And Disadvantages Of Injection Molding

- Advantages: It can be made of special ceramic materials with small size and special shape, which can be mass-produced and the cost is low;

- Disadvantages: It cannot be used for products with large size specifications, and the dimensional accuracy is limited.