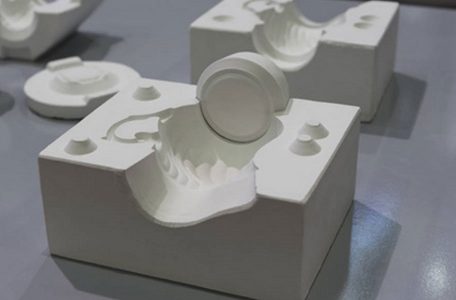

Ceramic molding process, including specific methods and molding equipment for ceramic molding. The ceramic molding process is one of the ceramic manufacturing processes. Let Pintejin Ceramics introduce the specific process and method of the ceramic molding process. The process of zirconia ceramic machining ceramic molding process is roughly as follows: raw materials are formed by gypsum or resin master mold by means of low pressure quick discharge or high pressure grouting – drying – glazing – firing – assembly – packaging, each All procedures are subject to full inspection or experimentation. The methods used in the ceramic forming process mainly include grouting, pressing, plastic forming and isostatic pressing. Below we Read more

The emergence and development of engineering ceramic cutting tools have raised the cutting technology to a new level. Ceramic tools were developed in the 1950s. The hardness of the tool material is 93HRA-94HRA, the bending strength is 800-1000MPa, and it can be cut normally at a high temperature of 1200-1300 °C. Alumina-based ceramic cutting tools were successfully developed in the 1960s and put into use in the 1970s. They are also one of the most widely used ceramic cutting tools at home and abroad. Since Shandong University began to develop alumina-carbide series composite ceramic tools in the 1980s, it has achieved remarkable results, and its mechanical properties have reached the Read more

An overview of the ceramic spray process The use of ceramic thermal spraying technology can not only improve the wear resistance, corrosion resistance, erosion resistance, thermal stability and chemical stability of machinery and equipment, but also endow common materials with special functions, such as high temperature superconducting coatings, biological coatings Therefore, thermal spraying technology will inevitably attract more and more attention and be more and more widely used in various industrial fields. However, the actual parts vary greatly due to their material, shape, size, application environment, service conditions, etc. In order to successfully use thermal spray coating to solve the technical problems faced, a specific process must be followed. Among Read more

Silicon nitride ceramic is an important structural ceramic material. It is a super-hard substance, which has lubricity and wear resistance. It is atomic crystal and is resistant to oxidation at high temperature. What are the characteristics of silicon nitride ceramics? ? Next, Pintejin Ceramics will introduce to you. Properties of Silicon Nitride Ceramics 1. Silicon nitride ceramic is a very high temperature resistant ceramic material. This material has no melting point under normal pressure, and will decompose directly when the temperature reaches 1870 °C. In actual use, once the temperature under normal pressure reaches 1200 degrees Celsius, the C mechanical hardness of silicon nitride ceramics will decrease. 2. As one Read more

The zirconia ceramic ring is made of high-purity alumina, which has the advantages of wear resistance, acid and alkali resistance, and long-term insulation. So how to choose a zirconia ceramic ring manufacturer? Next, Pintejin Ceramics will introduce to you. 1. Do you have precise machining equipment? Since modern household appliances are produced on the process line, there are certain requirements for the use specifications and appearance shapes of the supporting products, so when choosing a ceramic ring manufacturer with a reasonable price. It is necessary to know whether the manufacturer has sufficient precision instruments to produce product specifications that can be accepted by the mainstream market, so as to avoid Read more

Zirconia ceramics toughened alumina ZAT ceramics can be made into various ceramic parts after a series of ceramic machining, and can also be made into simple ceramic rods, ceramic plates, etc. In the process of making finished products, the molding method is also very important Step one, the following Pintejin Ceramics Factory will introduce to you the molding method of ZAT ceramics. ZTA ceramic powder molding method: Powder molding refers to transforming the powder into a green body with a certain shape, size and strength before sintering. Forming will affect the density of ZTA ceramic green body and the uniformity of its internal microstructure, which has a great impact on Read more

I introduced some applications of zirconia ceramic coating to you before, so do you know what is the process of making it? Below Pintejin Ceramics Factory will give you the answer. ZrO2 has low thermal conductivity and is a high-temperature resistant ceramic, so coating a layer of (<4mm) ZrO2 coating on the metal surface can improve the temperature resistance of the metal (prevent oxidation), prevent heat loss, and improve thermal efficiency. have a certain effect. Zirconia ceramic parts The ZrO2 coating process generally has the following ways: ①Using high temperature plasma spray fishing method. Taking advantage of the high temperature of the plasma, ZrO2 is melted and sprayed directly onto Read more

The mechanical properties of 995 alumina can be said to be the highest among alumina ceramics of different purities. It is often used in some high-tech industries. Let’s take a look at Pintejin Ceramics Factory to introduce its mechanical properties to you. 99.5 alumina ceramics are white powder or fine sand, with good fluidity and stable performance. It is used as a raw material in high-aluminum refractory materials, electromagnetic devices and polishing and grinding products. 995 alumina ceramic plunger has high density and high impact energy, which can greatly improve the grinding efficiency. The bottom wear can ensure the purity of the crushed material, and its wear resistance is 2030 Read more

Hot-pressing sintering has many advantages, but because it is unidirectionally pressurized, the shape of the prepared sample is simple, generally sheet or ring. In addition, for the samples of non-equiaxed crystal system, the flaky or columnar grains are seriously oriented after hot pressing. The hot isostatic pressing sintering method combines the advantages of both the hot pressing method and the pressureless sintering method. It can not only improve the density, inhibit the grain growth, and improve the performance of the product like the hot pressing sintering method, but also can like the pressureless sintering method. It produces products with very complex shapes and avoids the grain orientation of non-equiaxed samples, Read more

The ceramic spool has strong aging resistance and wear resistance, which determines that the use time of the ceramic spool is far longer than that of other spools. So what are the functions and advantages of the ceramic spool? Next, Pintejin Ceramics gives Let me introduce to you. The role of ceramic valve core Ceramic spools are widely used. Some old-fashioned single-cooling faucets and commonly used valve spools still use copper spools. Copper spools are not as durable as ceramic spools. Ceramic spools are more wear-resistant than copper spools, and will not destroy healthy water quality due to rust. At the same time, in actual use, the quality of ceramic Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump