The fluid zirconia ceramic dispensing valve mainly solves the automatic fluid control scheme, and is also a major breakthrough in industrial automation equipment. It matches different fluid dispensing valves for different viscous fluid materials, glue output requirements, and accuracy. The automatic integration of zirconia is very important, which solves many problems for many enterprise users, such as shortage of personnel and labor, low efficiency of manual dispensing operation, low qualified rate of products, large waste of fluid raw materials, etc., which improves the product quality and production capacity of enterprises, reduces the In view of the production cost and manufacturing cost, only continuous research and development innovation and intensive cultivation Read more

With the wide application of difficult-to-machine materials such as titanium alloys and superalloys, how to correctly select and reasonably use tools for efficient and high-quality machining has become a very important industry topic. The workpiece material and tool structure, materials, etc. promote each other, the development of the manufacturing industry is very rapid, and the continuous development of tools is the driving force for the continuous development of the manufacturing industry. At present, the tool materials widely used in the manufacturing industry mainly include tool steel (carbon tool steel, alloy tool steel and high-speed steel), cemented carbide, ceramics and superhard tool materials. Among them, cemented carbide tools account for the Read more

Pintejin Ceramics Factory is a manufacturer of ceramic parts. In the process of production and machining, the production equipment used is also very important. Today, I will explain the equipment problems and advantages of producing zirconia ceramic parts. The sand mill can use glass marbles, zirconia balls, and bearing steel balls as grinding materials. It is better to use a uniform particle size for each material. Before loading the material into the head, the material should be cleaned and selected in advance. The selection of a certain type of material during grinding depends on the permeability particle size and viscosity of the raw material to be milled. The standard is: Read more

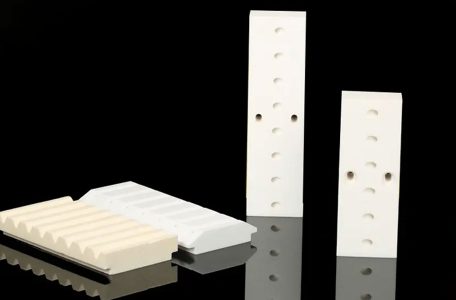

The products of alumina ceramic manufacturers include 95-99 alumina ceramics. I believe that everyone does not know the price of alumina ceramic manufacturers’ products very well. If you want to know what their prices are, the following is a professional manufacturer of zirconia. The manufacturer of ceramics and alumina ceramics, Pintejin Ceramics Factory, will introduce the price of alumina ceramics manufacturers. Alumina ceramic tube 1. If the price of 95 alumina ceramics from alumina ceramic manufacturers is 95 alumina ceramics from alumina ceramic manufacturers, then its price is relatively cheap, generally more than a dozen pieces, but It depends on what the market is like in each place. This will Read more

Pintejin Ceramics is a ceramics manufacturer specializing in the research, production and manufacture of industrial ceramic nozzles. Industrial ceramics are an indispensable development industry in modern technology. Industrial ceramics include many types and uses. For example, industrial ceramic nozzles have also been widely used in various industries in industrial ceramics. Below Pintejin Ceramics will introduce the types and uses of industrial ceramic nozzles. Zirconia Ceramic Nozzle Industrial ceramic nozzles are processed ceramic nozzles produced from ceramic materials, which have the advantages of wear resistance, high temperature resistance, corrosion resistance, etc. Precision ceramic nozzles are used in special industries such as: flamethrower, catalytic cracking nozzle, Texaco nozzle, manufacturing Granular nozzles, etc. Read more

Functional ceramic materials refer to materials that mainly use their non-mechanical properties in application. Such materials usually have one or more functions. Next, Pintejin Ceramics will introduce functional ceramic materials and their applications. Functional ceramic materials refer to materials that mainly use their non-mechanical properties in application. Such materials usually have one or more functions, such as electricity, magnetism, light, heat, chemistry, biology, etc., and some have coupling functions. , such as piezoelectric, piezoelectric, pyroelectric, electro-optic, acousto-optic, magneto-optic, etc. Due to the high development of science and technology, the performance, quality and requirements of ceramic materials are getting higher and higher, which has prompted some ceramics to develop into new Read more

We all know that the zirconia ceramics we are familiar with have the advantages of high temperature resistance, corrosion resistance, wear resistance and thermal shock resistance. In recent years, with the advancement of ceramic toughening and strengthening technology and the development of mechanical machining methods, the application range of zirconia ceramics has expanded rapidly. So do you know what major problems will be encountered in the machining of zirconia ceramics? The following is a brief introduction to the main problems encountered in the machining of zirconia ceramics by Pintejin Ceramics, a manufacturer specializing in the production of zirconia ceramics. Zirconia ceramic cutter 1. Processing methods of zirconia ceramics Processing methods Read more

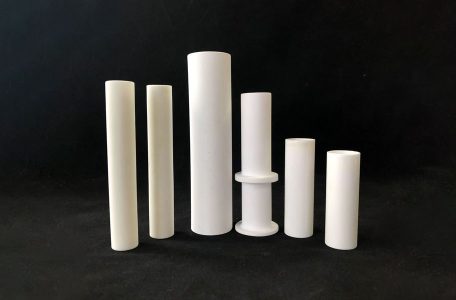

What is Zirconia Ceramics? What are the advantages? Do you know the answers to these two questions? Next, Pintejin Ceramics, a manufacturer specializing in the production of zirconia ceramics, will focus on introducing zirconia ceramics. Zirconia ceramic tube What is zirconia ceramic: Zirconia ceramic is white, yellow or gray when it contains impurities, generally contains HfO2, and is not easy to separate. There are three crystalline states of pure ZrO2 under normal pressure. The production of zirconia ceramics requires the preparation of powders with high purity, good dispersion properties, ultra-fine particles and narrow particle size distribution. There are many preparation methods for zirconia ultra-fine powder. The purification of zirconia mainly Read more

Alumina ceramics have been widely used in recent years, but due to the rise of zirconia ceramics, the two ceramics are now gradually evenly divided, and each has its own advantages. The following Pintejin Ceramics Factory will compare them. Ceramic toughness comparison: The toughness of zirconia ceramics is 4 times that of alumina ceramics. At the same time, when zirconia is dropped freely from a height of one meter, there will be some gaps and the alumina will be broken. Density comparison: The density of zirconia ceramics is twice that of alumina ceramics, and the compressive properties of zirconia are better. Zirconia ceramic parts Friction coefficient comparison: The friction coefficient Read more

General ceramic materials will have burrs on the surface when they are sintered. In order to meet the requirements of use, the surface is often brighter and smoother by polishing. Next, Pintejin Ceramics will introduce the polishing of mirror zirconia ceramics. After the zirconia ceramic parts are formed and sintered, there will be many uneven peaks and valleys on the surface, so it is necessary to grind and polish a super-finishing method that has a significant effect on ceramic roughness. From the perspective of material removal mechanism, grinding is a machining method between brittle failure and elastic removal of zirconia ceramic structural parts, while polishing is basically carried out within Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump