Although zirconia ceramics have many excellent characteristics, there are still many problems in the use of dispensing ceramics made of them. To sum up, there are 8 points. The following Pintejin Ceramics Factory will analyze it for you. 1. Ceramic dispensing valve dripping This situation often occurs after the dispense valve is closed. 95% of these cases are due to the use of needles that are too small in diameter. A needle that is too small can interfere with the flow of fluid and cause back pressure, which can result in dripping shortly after the valve is closed. A needle that is too small can also interfere with the valve’s Read more

Alumina ceramics is a material with alumina (AL2O3) as the main body, which has high strength, high hardness, corrosion resistance and good insulation. And it is a kind of high temperature resistant ceramics. Below Pintejin Ceramics Factory will introduce the process temperature in the production process of alumina ceramics. The operating ambient temperature of alumina ceramics mainly refers to the maximum process temperature used in the production process of alumina ceramics. In a production process, the higher the temperature used, the higher the relative manufacturing cost and the higher the yield. Not easy to control. The process temperature of the ceramic HTCC process itself is about 1300~1600℃ due to the Read more

Compared with metal materials, the machining performance of zirconia ceramics is obviously reduced a lot, because of its brittleness, but it is a high temperature resistant ceramics and has super wear resistance and corrosion resistance, high hardness and high strength, the following Pintejin Ceramics Factory How to solve the toughening method of ceramic matrix composites will be introduced. Since ceramics are polycrystalline sintered materials composed of ionic bonds or covalent bond grains, there is almost no slip or dislocation movement at room temperature. Once the material is in a stressed state, it is difficult to cause slip or dislocation. Plastic deformation is used to relax stress, and the energy required Read more

With the development of science and technology, more and more daily necessities have become intelligent, among which electronic ceramic parts play a great role. What will be the research direction of electronic ceramics in the future? The following Pintejin Ceramics Factory will conduct a brief analysis of its research and development. Electronic ceramics refer to ceramics that can utilize electrical and magnetic properties in the electronics industry. Electronic ceramics are ceramics with new functions that are finally obtained through precise control of the surface, grain boundaries and dimensional structure. It can be widely used in energy, household appliances, automobiles, etc. The research directions of electronic ceramics are: ① Study the Read more

The raw materials of ceramic plunger rods are generally wear-resistant and high-temperature resistant industrial ceramics, but its use still has certain limitations, so how to ensure its normal use in harsh environments? Below Pintejin Ceramics Factory will give you an analysis. A ceramic plunger includes a plunger body with a connecting end, the inside of the plunger body is a core body made of metal material, and the outer part of the core body is covered with a shell made of ceramic material; A sealant layer is arranged on the contact surface between the core body and the outer shell; a plugging head is arranged at the end of the Read more

The industrial ceramic shaft core and bushing are first made of wear-resistant ceramics, so the wear coefficient is very small. It is mainly divided into two types of ceramic shafts. The following Pintejin Ceramics Factory will analyze its application and advantages. Material classification of ceramic shaft and ceramic bushing: alumina ceramic shafts are divided into 2 types: 99% alumina ceramics and 95% alumina ceramics. 99 ceramics are mainly aimed at some small diameter shafts, mainly serving mid-end customers. 95 ceramics are generally aimed at some large diameter shafts. The main service and low-end customers. Zirconia ceramic shafts are mainly aimed at some ultra-high-speed rotating pumps, mainly serving high-end customers. Zirconia Read more

In the current situation of the prevalence of new industrial ceramic materials, more and more people are looking at business opportunities, and zirconia ceramic machining plants are also increasing. Faced with so many choices, how do we choose the machining that suits us? , the following Pintejin Ceramics Factory will take you to understand. 1. High-precision equipment is required. Because the machining of zirconia ceramics is extremely difficult, the requirements for equipment are also extremely high, and very high-precision imported equipment is required, and such equipment is also relatively expensive in terms of input cost, so Not every manufacturer will have it. Therefore, when choosing a manufacturer of zirconia ceramics, Read more

Diamond is the hardest substance in the world. It can be used as an abrasive tool for grinding zirconia ceramics, alumina ceramics, etc. So what types of diamond abrasive tools can be used as abrasive tools for zirconia ceramics? Pintejin Ceramics Factory gives three answers. Diamond Abrasives for Grinding of Zirconia Ceramics Zirconia ceramics Zirconia ceramics are high-hard, brittle, and difficult-to-machine ceramic materials, and diamond abrasive tools are commonly used grinding tools. According to the different bonding agents, diamond grinding wheels can generally be divided into resin-bonded diamond sand, ceramic-bonded diamond grinding wheels and metal-bonded diamond grinding wheels. 1. Resin-bonded diamond grinding wheels mostly use thermosetting resins, which have the Read more

machinable ceramics refers to ceramic materials that can be machined with traditional machining methods and maintain a certain precision. Are machinable ceramics resistant to high temperature? Next, Pintejin Ceramics will introduce to you. Machinable ceramics are high temperature resistant insulating materials and corrosion resistant electrical insulating materials that can be widely used in ultra-low temperature fields. Its use range is between -270°C and 800°C. Since the mica crystal in the machinable ceramic has a certain elasticity, it can prevent the extension of micro-cracks, so it has good thermal shock resistance. . Machinable ceramics can meet high-precision technical requirements due to various excellent comprehensive properties, without the need for mold design Read more

Bearings are one of the indispensable parts of modern industry, and the requirements for their materials are getting higher and higher. High-precision ceramic bearings have excellent performance and can replace metal materials. The following Pintejin zirconia ceramic machining factory will introduce the advantages of high-precision ceramic bearings. with the main use. Comparison of the performance of four bearing materials: ordinary bearing steel, stainless steel, silicon nitride and zirconia, ceramic bearings are an important mechanical foundation. Because high-precision ceramic bearings have excellent performance unmatched by metal bearings, high temperature resistance and high strength are leading the world in new materials. In the past ten years, it has been widely used in Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

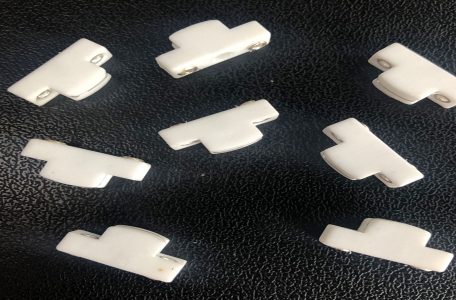

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

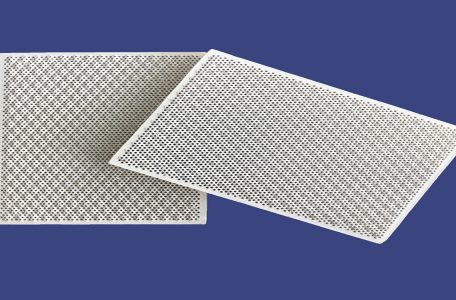

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump