Pintejin Ceramics Factory is a professional manufacturer of precision ceramics machining, which can provide customized precision ceramics machining and production according to drawings. Below, Pintejin Ceramics Factory will introduce the sintering technology of precision ceramics to us. Precision ceramic nozzle The sintering technology of precision ceramics mainly includes the following methods: Atmospheric pressure sintering of precision ceramics, also known as pressureless sintering. It belongs to the process of free sintering of the green body under atmospheric pressure. In the absence of external power, the sintering temperature of the material generally reaches the melting point of the material at 0.5-0.8. Solid-phase sintering at this temperature can induce sufficient atomic diffusion in Read more

Blog

Injection molding is to mix ceramic powder and organic binder, and inject ceramic powder into the metal mold cavity through an injection molding machine in the temperature range of 130-300 °C. blank. The advantages of the ceramic injection molding process are mainly reflected in the following aspects: It has superior molding ability and can produce precision parts with complex shapes. Since the raw material is finer powder particles, the sintering density is high, the relative theoretical density of solid phase sintering can reach more than 95%, and the liquid phase sintering can reach more than 99%, and its microstructure is fine and uniform, with Excellent mechanical properties. Injection molding is Read more

Although the zirconia ceramics we are familiar with have excellent performance and high hardness, it will inevitably require very precise machining during machining. Next, the Pintejin ceramics manufacturer will introduce to you the finishing methods and attention of zirconia ceramics. point. Finished zirconia ceramic tube Processing method of precision zirconia ceramic machining: Zirconia ceramic machining methods are commonly divided into two categories: mechanical machining, mold injection machining, etc. Among them, the mechanical machining method is highly efficient, so it is widely used in industry. Applications, especially diamond wheel grinding, lapping and polishing are common. Precautions for machining precision zirconia ceramic parts: Although there are many methods for machining precision zirconia Read more

Pintejin Ceramic Factory has recently purchased a 1050 centerless grinding machine, which is an indispensable ceramic machining machine in the machining of zirconia ceramics. Its main function is to finely grind and polish the outer diameter, which greatly improves the production efficiency of our factory. 1. The centerless grinder MT1050/M1050A adopts the grinding wheel frame to be fixed and the guide wheel frame to move. 2. The main shaft of the grinding wheel adopts multi-piece long bearing bush dynamic pressure oil film bearings, and the main shaft of the guide rail adopts an integral 1:30 cone sliding bearing; the grinding wheel and the guide wheel are of cantilever type structure. Read more

Alumina ceramics are made by using alumina as the main raw material, adding 6-30% of clay, magnesium oxide, calcium oxide, titanium oxide and other sintering accelerators, and sintering at 1450-1800 ℃ after mixing. The more alumina content, the better the inherent properties of alumina can be exerted, and the better the performance, but it becomes difficult to manufacture as the alumina content increases. The characteristics of alumina porcelain are that it still has good insulating properties at high temperature. Pure alumina porcelain can be used at a temperature of 800 ° C. Its mechanical strength is the highest among all oxide ceramics, and its thermal conductivity is large and thermal Read more

Zirconia ceramics and alumina ceramics are relatively common in the market, and their advantages are particularly prominent. Similar industrial ceramics, silicon nitride ceramics, also have some unique advantages. Next, let’s take a look at silicon nitride ceramics and its application in Use in aerospace and more! Silicon nitride ceramics are used in aerospace and military industry, mechanical engineering, communications, electronics, automobiles, energy, chemical biology and other fields because of their high temperature resistance, corrosion resistance, wear resistance and unique electrical properties. Especially in the field of high temperature structural ceramics, silicon nitride ceramics are new materials with the best comprehensive properties, the most application potential and the hope to replace Read more

Basic performance of zirconia ceramics , is gradually being adopted by decorative ceramics, such as colored zirconia ceramics, ceramic jewelry, etc. Zirconia ceramics is an inorganic non-metallic material with high temperature resistance, corrosion resistance, wear resistance and excellent electrical conductivity. It was used in the field of refractory materials in the early 1920s until the mid-1970s. Japan’s advanced countries have invested in the research and development of zirconia ceramic production technology and the production of zirconia ceramic series products, and further expanded the application field of zirconia ceramics to structural materials and functional materials. At the same time, zirconia ceramics are also encouraged by the national industrial policy. One of Read more

The development of the fine ceramics industry in China is on the rise, but it is technically different from foreign countries. However, with the support of the state for fine ceramics and the development of science and technology, my country’s fine ceramics industry will develop better and better. Below is an analysis of this industry by Pintejin Ceramics. Due to its excellent properties, fine ceramics are widely used in the fields of national defense, chemical industry, metallurgy, electronics, machinery, aviation, aerospace and biomedicine, and have become an important key material for the development of these fields. attention, its development also affects the development and progress of other industries to a Read more

Due to its unique semiconductor characteristics, semiconductor ceramics are suitable for equipment with special requirements for materials, etc. The following Pintejin ceramic zirconia machining factory will introduce you to semiconductor ceramics. Semiconductor ceramics refer to ceramic parts with semiconductor properties and electrical conductivity of about 10-6 to 105/m. The conductivity of semiconductor ceramics changes significantly due to changes in external conditions (temperature, light, electric field, atmosphere and temperature, etc.), so the physical quantity changes in the external environment can be converted into electrical signals to make sensitive components for various purposes. Thermal ceramics: also known as thermistor ceramics, refers to ceramics whose conductivity changes significantly with temperature. Thermal semiconductor ceramic Read more

In modern industry, there are many different kinds of ceramics, and their properties are very different. In the classification of ceramics, alumina ceramics is one of the ceramic materials with low cost. This material has good high temperature resistance and compression performance, and is very popular and purchased by customers. Zirconia ceramics make up for the insufficient tensile strength of alumina ceramics. Among the several types of raw materials, it is a structural ceramic with good physical properties at room temperature. Many gate valves, such as valve balls, high-pressure gate valves, and butterfly valve plates, are all made of zirconia ceramics. Let’s talk about silicon nitride ceramics, which should be Read more

Ceramic Machining Industry

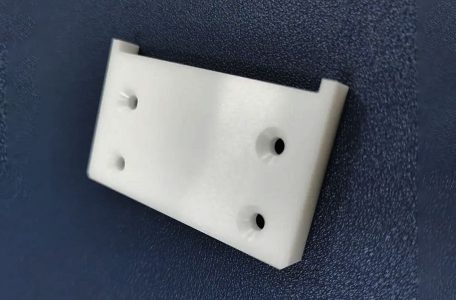

- Ceramic Flange

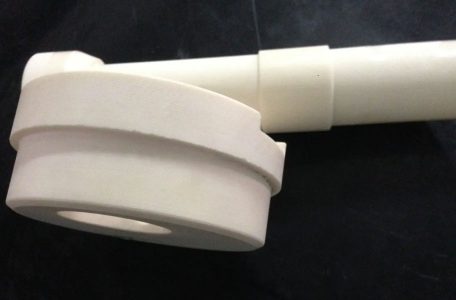

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

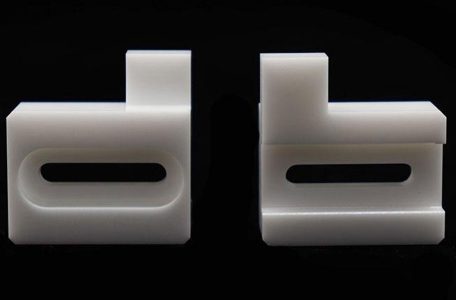

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump