The raw materials of ceramic plunger rods are generally wear-resistant and high-temperature resistant industrial ceramics, but its use still has certain limitations, so how to ensure its normal use in harsh environments? Below Pintejin Ceramics Factory will give you an analysis. A ceramic plunger includes a plunger body with a connecting end, the inside of the plunger body is a core body made of metal material, and the outer part of the core body is covered with a shell made of ceramic material; A sealant layer is arranged on the contact surface between the core body and the outer shell; a plugging head is arranged at the end of the Read more

Blog

The industrial ceramic shaft core and bushing are first made of wear-resistant ceramics, so the wear coefficient is very small. It is mainly divided into two types of ceramic shafts. The following Pintejin Ceramics Factory will analyze its application and advantages. Material classification of ceramic shaft and ceramic bushing: alumina ceramic shafts are divided into 2 types: 99% alumina ceramics and 95% alumina ceramics. 99 ceramics are mainly aimed at some small diameter shafts, mainly serving mid-end customers. 95 ceramics are generally aimed at some large diameter shafts. The main service and low-end customers. Zirconia ceramic shafts are mainly aimed at some ultra-high-speed rotating pumps, mainly serving high-end customers. Zirconia Read more

In the current situation of the prevalence of new industrial ceramic materials, more and more people are looking at business opportunities, and zirconia ceramic machining plants are also increasing. Faced with so many choices, how do we choose the machining that suits us? , the following Pintejin Ceramics Factory will take you to understand. 1. High-precision equipment is required. Because the machining of zirconia ceramics is extremely difficult, the requirements for equipment are also extremely high, and very high-precision imported equipment is required, and such equipment is also relatively expensive in terms of input cost, so Not every manufacturer will have it. Therefore, when choosing a manufacturer of zirconia ceramics, Read more

Diamond is the hardest substance in the world. It can be used as an abrasive tool for grinding zirconia ceramics, alumina ceramics, etc. So what types of diamond abrasive tools can be used as abrasive tools for zirconia ceramics? Pintejin Ceramics Factory gives three answers. Diamond Abrasives for Grinding of Zirconia Ceramics Zirconia ceramics Zirconia ceramics are high-hard, brittle, and difficult-to-machine ceramic materials, and diamond abrasive tools are commonly used grinding tools. According to the different bonding agents, diamond grinding wheels can generally be divided into resin-bonded diamond sand, ceramic-bonded diamond grinding wheels and metal-bonded diamond grinding wheels. 1. Resin-bonded diamond grinding wheels mostly use thermosetting resins, which have the Read more

machinable ceramics refers to ceramic materials that can be machined with traditional machining methods and maintain a certain precision. Are machinable ceramics resistant to high temperature? Next, Pintejin Ceramics will introduce to you. Machinable ceramics are high temperature resistant insulating materials and corrosion resistant electrical insulating materials that can be widely used in ultra-low temperature fields. Its use range is between -270°C and 800°C. Since the mica crystal in the machinable ceramic has a certain elasticity, it can prevent the extension of micro-cracks, so it has good thermal shock resistance. . Machinable ceramics can meet high-precision technical requirements due to various excellent comprehensive properties, without the need for mold design Read more

Bearings are one of the indispensable parts of modern industry, and the requirements for their materials are getting higher and higher. High-precision ceramic bearings have excellent performance and can replace metal materials. The following Pintejin zirconia ceramic machining factory will introduce the advantages of high-precision ceramic bearings. with the main use. Comparison of the performance of four bearing materials: ordinary bearing steel, stainless steel, silicon nitride and zirconia, ceramic bearings are an important mechanical foundation. Because high-precision ceramic bearings have excellent performance unmatched by metal bearings, high temperature resistance and high strength are leading the world in new materials. In the past ten years, it has been widely used in Read more

Generally ceramics are opaque, but optical ceramics are as transparent as glass, so they are called transparent ceramics. Generally, the reason why ceramics are opaque is that there are impurities and pores inside. The former can absorb light, and the latter can scatter light, so it is not transparent. Therefore, it is possible to obtain transparent ceramics if high-purity raw materials are selected and pores are eliminated by technological means. Transparent zirconia ceramics have the advantages of high transmittance in the visible-mid-infrared band, excellent mechanical strength, good thermal shock resistance, etc., and are the preferred materials for high temperature windows and infrared fairings. The production cost of zirconia ceramics is Read more

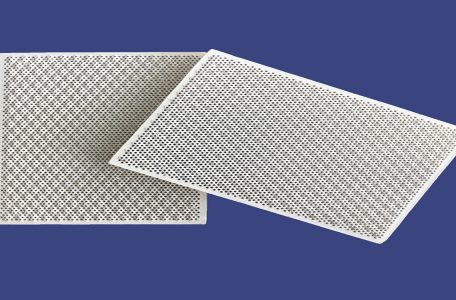

With the continuous development and progress of science and technology, ceramic sheets have been widely used in various fields, so what are the two types of ceramic sheets? Next, Pintejin Ceramics will introduce to you. 1. Optical functional ceramic sheet In terms of optical functional ceramics: due to the small size effect, nanoparticles have optical properties that conventional bulk materials do not have, such as optical nonlinearity, light absorption, light reflection, light transmission characteristics, etc. Academician Hong Maochun from the Fujian Institute of Physics and Architecture of the Chinese Academy of Sciences has developed optical functional ceramic materials with excellent performance by using nanotechnology, focusing on three interrelated sintered Read more

Structural ceramics refer to ceramics used in various industrial sectors to manufacture mechanical equipment and machining tools. Structural ceramics are a kind of spiritual material. What are the characteristics and types of structural ceramics? Next, Pintejin ceramics will introduce to you. . Features of Structural Ceramics 1. Structural ceramics mainly refer to a large class of new ceramic materials that exert their mechanical, thermal, chemical and other properties. They can serve in many harsh working environments, and thus become the key to the realization of many emerging science and technology. 2. Structural ceramics have the characteristics of superior strength, hardness, insulation, heat conduction, high temperature resistance, oxidation resistance, Read more

There are many places where alumina ceramic structural parts are used. During use, alumina ceramic structural parts will also be damaged, which will cause irreparable losses to users. So what are the reasons for the damage to alumina ceramic structural parts? ? Next, Pintejin Ceramics will introduce to you. 1. External force A major factor for the wear of alumina ceramic structural parts is the strong external force, which is generally caused by impact force and pressure during operation. Due to the strong external force, it is worn or broken, which is unfavorable for the alumina ceramic structure. We should try our best to avoid the collision with the object Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

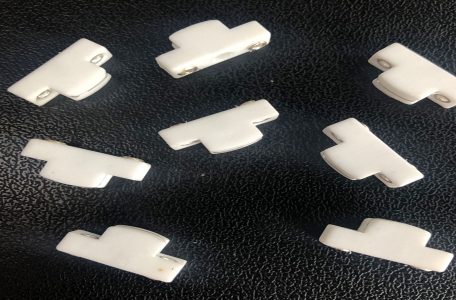

- Ceramic Structure Parts

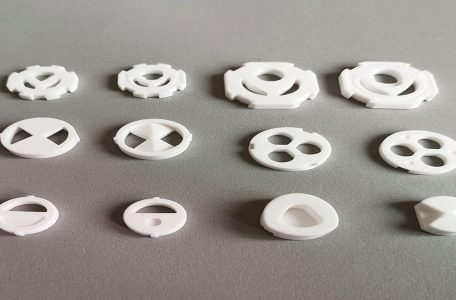

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump