Recently, some people have raised the issue that zirconia ceramics will crack after sintering, so what is the truth? Below is the answer from Pintejin Ceramics. The pure zirconia ceramics were sintered and cracked. The zirconia made by the grouting method was naturally air-dried for 3 days and then placed in a high-temperature furnace. The temperature was raised to 1450°C at 3°C/min and 5°C/min respectively, held for 4 hours, and cooled out of the furnace. Cracking occurs. Due to the high hardness of stabilized zirconia, it is generally used in a steel ball mill for ductile ink, pickling after the ductile ink, and then neutralized with water and dried. Using Read more

Blog

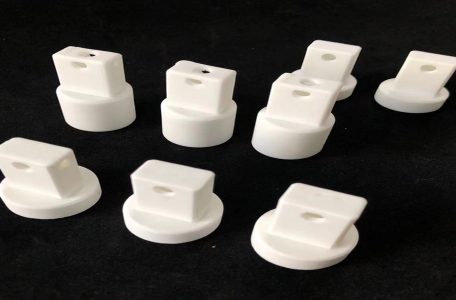

Industrial ceramics are widely used due to their high wear resistance, high hardness, and especially excellent insulating properties. Insulating porcelain, also known as device porcelain, is widely used in electrical equipment. Commonly used products are: high-frequency insulators, sockets, porcelain shafts, porcelain tubes, substrates, band switches, etc. Zirconia Industrial Ceramic Parts The basic requirements for insulating porcelain are low dielectric constant ε, small dielectric loss tanδ, high insulation resistivity ρ, high breakdown strength E, and good dielectric temperature characteristics and frequency characteristics. In addition, high mechanical strength and chemical stability are also required. Insulation porcelain mainly refers to porcelain products used for installation, fixation, support, protection, insulation, isolation and connection of Read more

Fine ceramics is a kind of industrial ceramics that uses highly selected high-purity chemical products as raw materials, and is used in industry. Fine ceramics include zirconia ceramics, silicon nitride ceramics, etc., which are very different from traditional ceramics. Let Pintejin ceramics introduce you to the main differences between the two.Fine ceramic parts The main differences between fine ceramics and traditional ceramics: 1. In terms of raw materials, it breaks through the boundaries of traditional ceramics with clay as the main raw material. Special ceramics generally use oxides, nitrides, silicides, borides, carbides, etc. as the main raw materials. The main difference is that the various chemical composition, morphology, particle size Read more

Zirconia Reaction Sintering Mode Zirconia ceramics can be used in various fields due to their unique properties, but there are problems such as high preparation cost and difficulty in preparing large-sized special-shaped components. Drawing on the experience of preparing reactive sintered alumina ceramics, the Al and AIN powders were fully mixed, then formed by cold isostatic pressing and reacted in a zirconium gas atmosphere. The newly generated Al particles after zirconization of the Al powder are nanoparticles, and the “old” Al particles are combined during the sintering process to obtain reaction-bonded aluminum anchor (RBA) ceramics. Since Al zirconium is accompanied by a quantitative volume expansion, it can partially offset the Read more

The crystal structure of zirconia ceramics is the basis of its wear resistance and high temperature resistance. When zirconia ceramics have a special crystal structure, it has a series of excellent characteristics. Then what is its crystal structure? Introduce everyone. The materials of zirconia ceramics and zirconia toughened alumina ceramics are widely used. Due to the excellent physical and chemical properties of zirconia, it has a prominent position in engineering ceramics and advanced ceramics, such as ceramic rods, piston crowns of ceramic engines. and many more. There are three stable allotropes of zirconia: monoclinic, cubic and tetragonal. The monoclinic phase of pure zirconia is stable from room temperature to 1170°C, Read more

There are many places where alumina ceramics are used, and alumina ceramics are also damaged during use. What are the reasons for the damage to alumina ceramics? Next, Pintejin ceramics will introduce to you. 1. External force A major factor for the wear of alumina ceramics is the strong external force, which is generally caused by impact force and pressure during operation.Due to the strong external force, it is worn or broken, which is unfavorable for alumina ceramics. We should try our best to avoid collision with objects during operation to minimize damage. 2.The influence of the external environment General environmental factors include the influence of the medium in Read more

Ceramic rods are very particular in the process of production and material selection. The produced ceramic rods are both good and bad, so how to identify the pros and cons of ceramic rods? Below Pintejin Ceramics Factory will give you an analysis. Due to the lack of a certain understanding of ceramic rods, I do not know how to choose when purchasing, resulting in the quality of the final ceramic rods that do not meet the requirements. The following small series will introduce you to several methods of selecting ceramic rods, hoping to help you. Fine zirconia ceramic rod The first is to verify the quality of the ceramic rod Read more

The ceramic sealing ring is mainly used as a sealing device, and acts as a matching object in some harsh environments to achieve a sealing effect between the two parts. It is mainly made of high temperature resistant zirconia ceramics and alumina ceramics. Then the following Pintejin Ceramics Factory Its application range and performance characteristics will be analyzed in detail. Ceramic sealing ring for mechanical structure is superior to other materials in chemical corrosion resistance, wear resistance, high temperature resistance and other properties. It is processed from ceramic powder through vacuum hot pressing sintering, grinding, polishing and other processes. Widely used in machinery, chemical, petroleum, food, pharmaceutical, automotive and other Read more

High temperature resistant industrial ceramics refers to ceramics with high temperature resistance for industrial production and industrial products. Now Pintejin Zirconia Ceramics Factory will tell you the common high temperature resistant industrial ceramics. High temperature-resistant industrial ceramics are a type of fine ceramics, which can play mechanical, thermal, chemical and other functions in applications. Because industrial ceramics have a series of advantages such as high temperature resistance, corrosion resistance, wear resistance and erosion resistance, they can replace metal materials and organic polymer materials in harsh working environments. 99 alumina high temperature industrial ceramic flange Alumina Ceramics: The ceramic is a ceramic with AL2O3 as the main component (the mass fraction Read more

Alumina ceramics is a kind of ceramic products using alumina as the main material. Next, Pintejin Ceramics will introduce the molding method of alumina ceramic materials. Forming method of alumina ceramic material 1. Dry-pressing molding: The thousand-pressing molding technology of alumina ceramic materials is limited to objects with a simple shape, an inner wall thickness of more than 1mm, and a length-to-diameter ratio of not more than 4:1. The molding method is uniaxial or bidirectional, and the press has two types: hydraulic and mechanical, which can be semi-automatic or fully automatic. The maximum pressure of the press is 200Mpa. Due to the uniform stroke pressure of the Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump