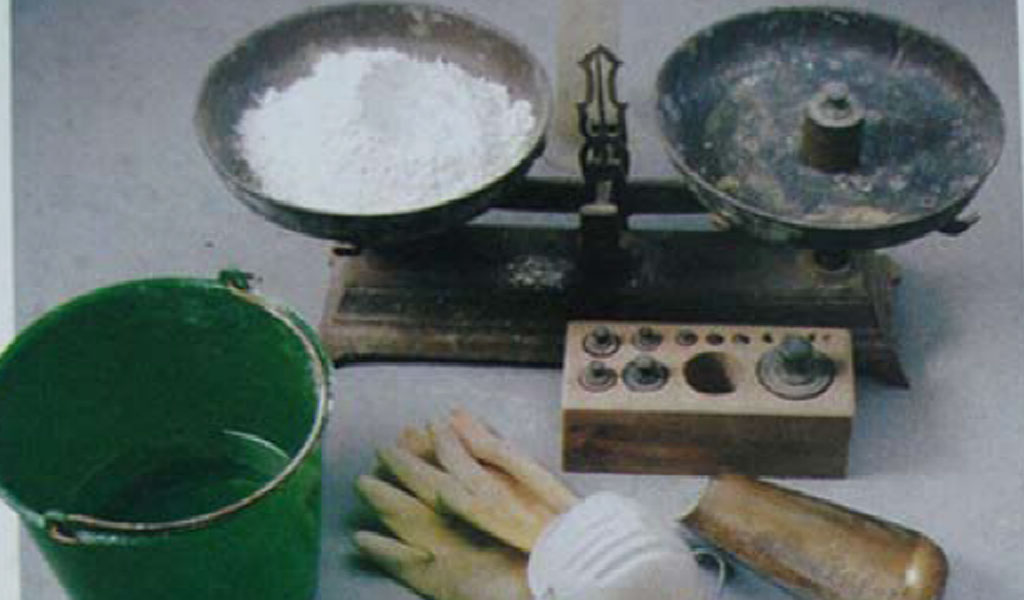

Mix according to the relative proportions of gypsum and water. Usually the grouting mold water and gypsum are mixed in a ratio of 1:1.2, and the blank mold is mixed in a ratio of 1:1.5. The gypsum should be screened before mixing to screen out the hard lumps and other impurities, which will affect the quality of the gypsum mold.

Prepare to weigh a good proportion of water and gypsum, slowly sprinkle the gypsum into the bucket with the relative proportion of water, and pay attention to rubbing your hands during the pouring process to further screen the impurities in the gypsum. It is not advisable to stir the gypsum in the process of spreading it. Slowly sink it into the water until no powdery gypsum can be seen. At this time, stir it by hand or with a mixer to make it blend with the water. While stirring, pay attention to the particles and other particles when mixing. To remove impurities, stir evenly at a frequency so as not to have air mixed in. At the same time, beat the vessel containing the gypsum mixture to release the foam generated during mixing. During the process, you will find that air bubbles or some light impurities float to the surface from time to time. Use a container or hand to scoop them out and throw them into the trash can.

Feel the consistency of the gypsum mixture during the mixing process. If it is too thin, it will affect the drying time of the gypsum mold, or it will flow out from the gap; if it is too thick, the details of the mud draft may not be covered by the gypsum mixture, causing holes to appear. ; It will also cause the phenomenon that the gypsum mixture dries too quickly, which will gradually produce an intuitive judgment of the consistency in the process of practice. When the plaster mixture is of the right consistency, it is ready to be poured into the model. In the process of pouring into the model, the flow of the gypsum mixture should be slow and uniform. Too fast pouring will produce a large number of air bubbles and affect the quality of the gypsum mold. First pour the gypsum mixture into a corner or the high point of the mud manuscript to make it flow slowly, and then cover the entire mud manuscript. Pay attention to the uniform thickness of the gypsum in each part, and replenish the thinner parts in time to achieve the ideal After the thickness of the plaster mold is slowly cooled, the plaster mold is trimmed. The surface of the plaster mold is polished with tools to make it flat, and the edge of the plaster mold is chamfered to a certain extent, so as to avoid bumping and falling off or cracking during daily use.

In the process of mixing and using gypsum, we should pay attention to the following issues:

- Select the appropriate plaster and mixing ratio according to the requirements of the work

- Gypsum is easily contaminated with mud, and it is inevitable that you will mix gypsum during the operation. If this happens, if the mud mixed with gypsum is not removed, an explosion will occur during the kiln firing process. Therefore, in the process of operation, we should try our best to separate the mud and gypsum. If the gypsum is accidentally mixed into the mud, it should be removed in time and the operating environment should be cleaned up.

- When the gypsum is mixed and poured, air bubbles will be generated, which will affect the water absorption capacity of the gypsum mold and shorten the service life of the gypsum mold. When the gypsum is mixed, we reduce the generation of air bubbles by controlling the stirring speed and frequency, and tapping the bottom and surrounding of the container. And promote the removal of air bubbles; when pouring the gypsum mixture, reduce the appearance of air bubbles by controlling the pouring speed and pouring method.

- Treatment of waste gypsum: The gypsum undergoes a chemical reaction and will solidify rapidly after heating. After the gypsum mixture is poured, it should be placed in a container for cleaning. If the gypsum has solidified, use a shovel and other tools for treatment. The removed waste gypsum should not be flushed into the sink, as the gypsum is not easy to decompose and may cause blockage of the sewer pipe. Clean it and put it in the trash can for disposal.

- Storage of gypsum and gypsum molds: Store gypsum in a cool and dry place, so that it is not easy to be affected by moisture and aging and cannot be used. Gypsum molds can only be used after drying. The drying time depends on factors such as indoor and outdoor temperature, thickness and volume of the mold. In the case of relative conditions, the electric drying box can be used for accelerated drying, and the mold itself will not be damaged. Through the investigation of Jingdezhen workshops, people generally use natural drying and drying by utilizing conditions. By observing that many ceramic workers disassemble the mold composed of two or more molds and dry them separately during the drying process, it is easy to deform the mold, and the larger the mold, the easier it is to deform.

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies