The shape, size and particle size distribution of ceramic powder are an important factor affecting the quality of injection molding. The addition of organic binders will cause the dimensional shrinkage of ceramic injection molded products after sintering to be much greater than that of molded products. In order to prevent the deformation and dimensional accuracy decline caused by a large amount of shrinkage, the content of solid powder in the material system must be increased to reduce shrinkage [6].

In theory, spherical powder can maximize the loading capacity, but there is another problem that the meshing force between the spheres is very small, and it is difficult to maintain the shape of the green body in the subsequent degreasing stage. At the same time, the green body performance in the subsequent degreasing and sintering process is guaranteed to be intact.

Found that when the specific surface area of the powder was controlled to a certain value in Al2O3 injection molding, the loading amount increased, and the feed viscosity also increased. When the load was increased to 65%, the feed could not flow. Wang Bo et al.

Used injection molding technology to prepare ZTA ceramics. The study found that the initial bulk density of the solid phase in the green body is positively correlated with the solid content of the powder. Increasing the solid content will ultimately help improve the sintered density and mechanical properties of the ceramic.

However, when the solid content is too high, due to the excessive viscosity, pore defects that cannot be discharged during the sintering process will be formed in the green body, which will deteriorate the performance of the ceramic. Powder particle size is another important factor affecting injection molding. The fine powder can increase the ultimate packing density and increase the driving force of sintering, and reduce the sintering temperature. However, because the specific surface area of the powder is too large, it is easy to agglomerate between the particles, which increases the viscosity of the mixture, and it is difficult to fully and evenly disperse . It has been found that irregularities, large particle size differences or doping of powder particles of different shapes during the injection molding stage have a greater impact on the final product properties.

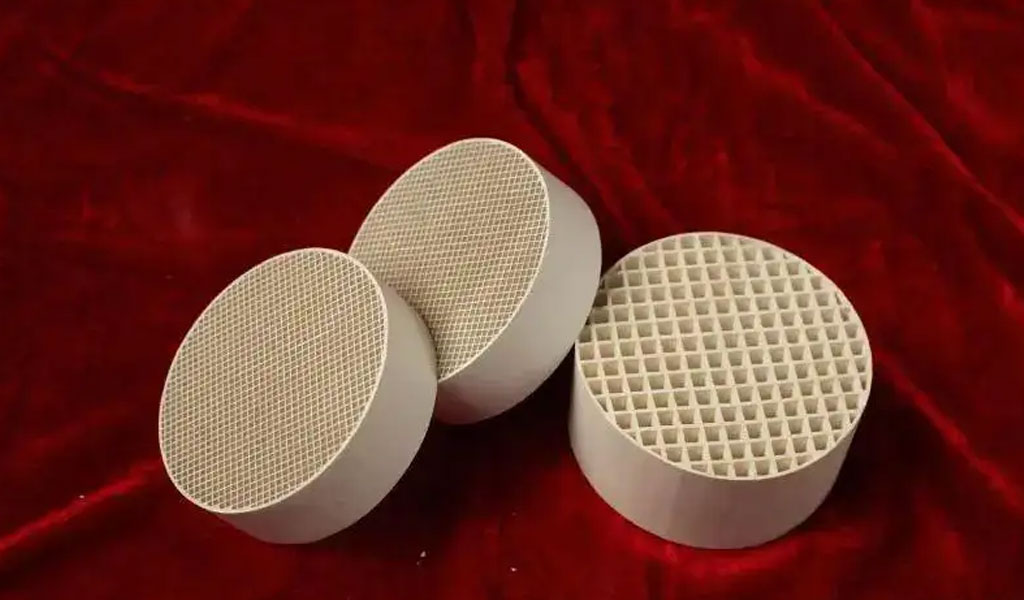

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies