Alumina ceramic round rod is a kind of ceramic rod and also a kind of alumina ceramic product. Then let Pintejin Ceramics, a professional manufacturer of zirconia ceramic machining, take you to know it. Alumina ceramic round rod Features of alumina ceramic round rod: A. The strength is higher than that of clay ceramics, with high hardness and good wear resistance; B. High temperature resistance, can be used for a long time at a high temperature of 1600 degrees; C. Strong corrosion resistance; D. Good electrical insulation properties, especially outstanding electrical insulation properties at high temperatures, with a withstand voltage of more than 8000V per millimeter of thickness. Alumina ceramic Read more

Blog

Pintejin Ceramics is a ceramics manufacturer specializing in the research, production and manufacture of industrial ceramic nozzles. Industrial ceramics are an indispensable development industry in modern technology. Industrial ceramics include many types and uses. For example, industrial ceramic nozzles have also been widely used in various industries in industrial ceramics. Below Pintejin Ceramics will introduce the types and uses of industrial ceramic nozzles. Zirconia Ceramic Nozzle Industrial ceramic nozzles are processed ceramic nozzles produced from ceramic materials, which have the advantages of wear resistance, high temperature resistance, corrosion resistance, etc. Precision ceramic nozzles are used in special industries such as: flamethrower, catalytic cracking nozzle, Texaco nozzle, manufacturing Granular nozzles, etc. Read more

Functional ceramic materials refer to materials that mainly use their non-mechanical properties in application. Such materials usually have one or more functions. Next, Pintejin Ceramics will introduce functional ceramic materials and their applications. Functional ceramic materials refer to materials that mainly use their non-mechanical properties in application. Such materials usually have one or more functions, such as electricity, magnetism, light, heat, chemistry, biology, etc., and some have coupling functions. , such as piezoelectric, piezoelectric, pyroelectric, electro-optic, acousto-optic, magneto-optic, etc. Due to the high development of science and technology, the performance, quality and requirements of ceramic materials are getting higher and higher, which has prompted some ceramics to develop into new Read more

The ductile domain grinding, one of the grinding methods of zirconia ceramics, was introduced above. Next, Pintejin Ceramics Factory will continue to introduce the second grinding method, laser preheat-assisted grinding. The middle hexagonal dividing line zirconia ceramic has the common characteristics of high hardness, high brittleness and low fracture toughness of ceramic materials, which makes it easy for ceramic materials to produce deformed layers, surface/subsurface microcracks, material powdering, Defects such as fuzzy surfaces, phase transition regions, and residual stress limit the further expansion of the application range of ceramic materials. Ceramic materials, especially those with higher hardness, such as zirconia ceramics, have always been “hard to process”, so that the Read more

Insulating ceramic sheets are mainly used in industry. Pintejin Ceramics is a zirconia ceramics manufacturer specializing in the production and machining. The following is an introduction to the production process of insulating ceramic sheets by Pintejin Ceramics. Insulating ceramic sheet Insulating ceramic sheet is an industrial ceramic part. The specific process flow chart is as follows: Ingredients – Mixing and grinding – Pre-firing – Secondary grinding – Granulation – Forming – Plastic removal – Sintering into porcelain – Shape machining – Electrode – High voltage polarization – Aging test. 1. Ingredients: carry out pre-machining of materials, remove impurities and moisture, and then weigh various raw materials according to the proportion Read more

We all know that the zirconia ceramics we are familiar with have the advantages of high temperature resistance, corrosion resistance, wear resistance and thermal shock resistance. In recent years, with the advancement of ceramic toughening and strengthening technology and the development of mechanical machining methods, the application range of zirconia ceramics has expanded rapidly. So do you know what major problems will be encountered in the machining of zirconia ceramics? The following is a brief introduction to the main problems encountered in the machining of zirconia ceramics by Pintejin Ceramics, a manufacturer specializing in the production of zirconia ceramics. Zirconia ceramic cutter 1. Processing methods of zirconia ceramics Processing methods Read more

EDM mainly produces high-temperature melting and vaporization of materials through discharge between electrodes. Therefore, the machinability of materials mainly depends on the thermal properties of materials, such as melting point, specific heat, thermal conductivity, etc., while the mechanical properties of materials have little influence. . EDM is suitable for the machining of superhard conductive materials. Since most ceramic materials are electrical insulators, electrical discharge machining was rarely used in the past. But in recent years, many high-performance ceramics contain conductive materials such as TiC, which makes EDM possible. (1) Processing of conductive ceramics A considerable part of ceramics has a certain degree of conductivity, so it can be directly processed Read more

What is Zirconia Ceramics? What are the advantages? Do you know the answers to these two questions? Next, Pintejin Ceramics, a manufacturer specializing in the production of zirconia ceramics, will focus on introducing zirconia ceramics. Zirconia ceramic tube What is zirconia ceramic: Zirconia ceramic is white, yellow or gray when it contains impurities, generally contains HfO2, and is not easy to separate. There are three crystalline states of pure ZrO2 under normal pressure. The production of zirconia ceramics requires the preparation of powders with high purity, good dispersion properties, ultra-fine particles and narrow particle size distribution. There are many preparation methods for zirconia ultra-fine powder. The purification of zirconia mainly Read more

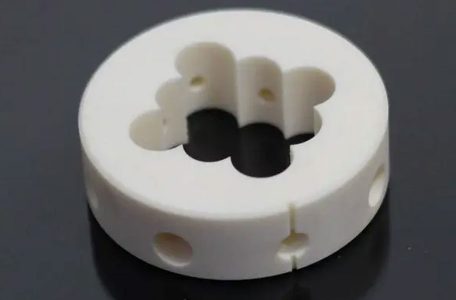

Introduction of rotary valve type zirconia ceramic liquid injection pump Zirconia ceramics is a material with excellent corrosion resistance and wear resistance. The ceramic liquid injection pump is widely used in batteries, medicine, electronics, machinery, chemical textiles and other industries with the help of the excellent performance of zirconia ceramics. The rotary valve type zirconia ceramic liquid injection pump is generally a centrifugal pump. Its impeller, volute, shaft seal cavity and suction and discharge pipes are all made of zirconia ceramic material. It is mainly used to transport strong corrosive liquids such as hydrochloric acid, sulfuric acid and nitric acid. , can not transport fluorine-containing materials and concentrated lye. The Read more

Alumina ceramics have been widely used in recent years, but due to the rise of zirconia ceramics, the two ceramics are now gradually evenly divided, and each has its own advantages. The following Pintejin Ceramics Factory will compare them. Ceramic toughness comparison: The toughness of zirconia ceramics is 4 times that of alumina ceramics. At the same time, when zirconia is dropped freely from a height of one meter, there will be some gaps and the alumina will be broken. Density comparison: The density of zirconia ceramics is twice that of alumina ceramics, and the compressive properties of zirconia are better. Zirconia ceramic parts Friction coefficient comparison: The friction coefficient Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump