Silicon nitride ceramic is an important structural ceramic material. It is a super-hard substance, which has lubricity and wear resistance. It is atomic crystal and is resistant to oxidation at high temperature. What are the characteristics of silicon nitride ceramics? ? Next, Pintejin Ceramics will introduce to you. Properties of Silicon Nitride Ceramics 1. Silicon nitride ceramic is a very high temperature resistant ceramic material. This material has no melting point under normal pressure, and will decompose directly when the temperature reaches 1870 °C. In actual use, once the temperature under normal pressure reaches 1200 degrees Celsius, the C mechanical hardness of silicon nitride ceramics will decrease. 2. As one Read more

Blog

What are the types of special ceramics? What are the new developments in the application of special ceramics? The following will be introduced by Pintejin ceramic manufacturers. Special alumina ceramic plate 1. Classification of special ceramics: According to their application functions, special ceramics can be roughly divided into two categories: high-strength, high-temperature resistant and composite structural ceramics and electrical and electronic functional ceramics. Inorganic materials with special formula are added to the ceramic blanks, which are sintered at a high temperature of about 1360 degrees to obtain stable and reliable anti-static properties and become a new type of special ceramics, which usually have one or more functions, such as: electricity, Read more

The zirconia ceramic ring is made of high-purity alumina, which has the advantages of wear resistance, acid and alkali resistance, and long-term insulation. So how to choose a zirconia ceramic ring manufacturer? Next, Pintejin Ceramics will introduce to you. 1. Do you have precise machining equipment? Since modern household appliances are produced on the process line, there are certain requirements for the use specifications and appearance shapes of the supporting products, so when choosing a ceramic ring manufacturer with a reasonable price. It is necessary to know whether the manufacturer has sufficient precision instruments to produce product specifications that can be accepted by the mainstream market, so as to avoid Read more

With the continuous development of science and technology, precision ceramic plungers have been widely used in medical equipment, environmental engineering, petroleum, chemical and other industries. How do consumers check the quality of precision ceramic plungers when purchasing precision ceramic plungers? Next, Pintejin ceramic manufacturers will explain how to test the quality of precision ceramic plungers. Alumina Ceramic Plunger Precision ceramic plunger is an ideal replacement for similar metal pumps because metal materials are more susceptible to corrosion in use, while precision ceramic plungers are highly resistant to corrosion. In addition, the precision ceramic plunger is produced with modern engineering ceramic materials, so it also has super hard wear resistance, so Read more

Zirconia ceramics toughened alumina ZAT ceramics can be made into various ceramic parts after a series of ceramic machining, and can also be made into simple ceramic rods, ceramic plates, etc. In the process of making finished products, the molding method is also very important Step one, the following Pintejin Ceramics Factory will introduce to you the molding method of ZAT ceramics. ZTA ceramic powder molding method: Powder molding refers to transforming the powder into a green body with a certain shape, size and strength before sintering. Forming will affect the density of ZTA ceramic green body and the uniformity of its internal microstructure, which has a great impact on Read more

I introduced some applications of zirconia ceramic coating to you before, so do you know what is the process of making it? Below Pintejin Ceramics Factory will give you the answer. ZrO2 has low thermal conductivity and is a high-temperature resistant ceramic, so coating a layer of (<4mm) ZrO2 coating on the metal surface can improve the temperature resistance of the metal (prevent oxidation), prevent heat loss, and improve thermal efficiency. have a certain effect. Zirconia ceramic parts The ZrO2 coating process generally has the following ways: ①Using high temperature plasma spray fishing method. Taking advantage of the high temperature of the plasma, ZrO2 is melted and sprayed directly onto Read more

Common zirconia toughened ceramics are: zirconia-Mg0, zirconia-alumina, zirconia-Yz 03, zirconia-Ca0. Now developed zirconia-Ce02, Y2 03-zirconia-Hf02 and so on. In addition, there are whisker (fiber)-zirconia composite toughened ceramics. Its toughness is shown in Table 2-1-10. Table 2-1-10 KI c value of several toughened ceramic materials Material Kic (MN . m-3/2) ZrOl-Y203 (pseudotetragonal) 6~9 Zirconia-Ca0 (precipitation strengthening) 9.6 Oxidation Zirconium-Mg0 (precipitation strengthening) 5.7 Zirconia (partially stabilized-stable phase) 1.1 Zirconia-A12 0a 9.8 Sia N4 4.8~5.8 SiC 3.4 B4C 6.0 Alz Oa 4.5 Spinel single crystal 1.3 It can be seen from the above table that the toughened ceramic material has much higher mechanical properties than the previous structural materials such as Sia N4 Read more

The mechanical properties of 995 alumina can be said to be the highest among alumina ceramics of different purities. It is often used in some high-tech industries. Let’s take a look at Pintejin Ceramics Factory to introduce its mechanical properties to you. 99.5 alumina ceramics are white powder or fine sand, with good fluidity and stable performance. It is used as a raw material in high-aluminum refractory materials, electromagnetic devices and polishing and grinding products. 995 alumina ceramic plunger has high density and high impact energy, which can greatly improve the grinding efficiency. The bottom wear can ensure the purity of the crushed material, and its wear resistance is 2030 Read more

In the industrial industry, ceramic parts are constantly developing. Today, Pintejin Ceramics Factory will introduce the advantages of ceramic parts. This kind of ceramic parts is often used in industrial equipment parts. Ceramic tube is a chemical substance with strong covalent bond, and its Si-C bond inorganic compound is only about 12%. Therefore, it also has physical properties, oxidation resistance, high wear resistance and low friction resistance. Industrial ceramic tubes are mainly used in the production and manufacture of power electronic technology industrial production, such as the casing of high-frequency power rectifier tubes, electric vacuum tube power switches, etc. Laminated glass is the raw material of the rectifier tube tube Read more

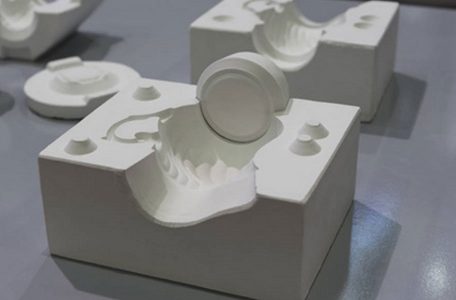

Hot-pressing sintering has many advantages, but because it is unidirectionally pressurized, the shape of the prepared sample is simple, generally sheet or ring. In addition, for the samples of non-equiaxed crystal system, the flaky or columnar grains are seriously oriented after hot pressing. The hot isostatic pressing sintering method combines the advantages of both the hot pressing method and the pressureless sintering method. It can not only improve the density, inhibit the grain growth, and improve the performance of the product like the hot pressing sintering method, but also can like the pressureless sintering method. It produces products with very complex shapes and avoids the grain orientation of non-equiaxed samples, Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump