There are many sintering methods for zirconia ceramic rods, such as isostatic pressing sintering, hot pressing sintering, etc. The following Pintejin Ceramics Factory will mainly give a brief introduction to the hot pressing sintering of ceramic rods, and mainly introduce its sintering methods and characteristics.

Hot pressing sintering of ceramic rods is a pressure sintering method with unidirectional pressure, and its principle is very simple. Definition of hot pressing sintering: a sintering method in which dry powder is filled into a mold, and then heated while pressing in a uniaxial direction, so that molding and sintering are completed at the same time. The hot-pressing sintering process is simply dry pressing at high temperature, that is, only the mold and the product need to be heated at the same time and a certain pressure is applied, so the powder does not need to be formed during hot-pressing sintering.

Ceramic plunger rod In hot pressing sintering, the heating method is still electric heating method, and the pressing method is oil pressure method. The mold can use graphite mold or alumina ceramic mold according to different requirements. Usually, the graphite mold must be used in a non-oxidizing atmosphere, and the operating pressure can reach 70MPa. Graphite molds are simple to make and have low cost. The working pressure of alumina mold can reach 200MPa, which is suitable for oxidizing atmosphere, but it is difficult to manufacture, high cost and low life.

The characteristics of hot-pressing sintering: due to the simultaneous heating and pressing, the powder is in a thermoplastic state, which is conducive to the contact and diffusion of particles and the process of flow and mass transfer, so the molding pressure is only 1/10 of that of cold pressing; It can reduce the sintering temperature and shorten the sintering time, thereby resisting the growth of grains, and obtaining products with fine grains, high density and good mechanical and electrical properties. Ultra-high purity ceramic products can be produced without the addition of sintering aids or forming aids. The disadvantage of hot pressing sintering is that the process and equipment are complicated, the production control requirements are strict, the mold material requirements are high, the energy consumption is large, the production efficiency is low, and the production cost is high.

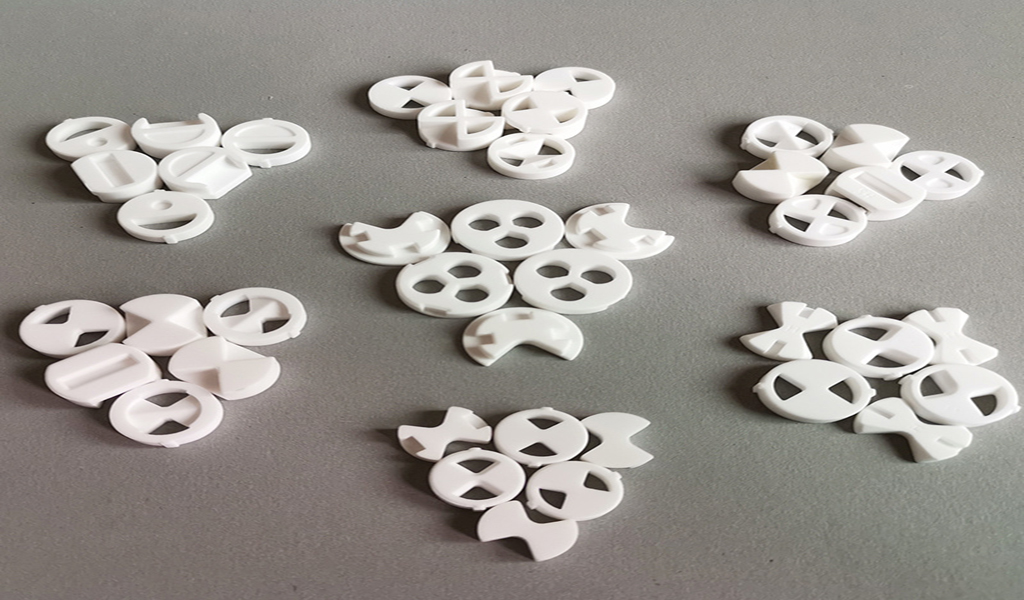

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies