Ceramic HIP sintering technology can produce materials with uniform microstructure, finer and denser grains at lower sintering temperature, and can produce products with complex shapes. So what are the characteristics of HIP sintering for zirconia ceramics? What? Next, Pintejin Ceramics will introduce to you.

The hot pressing sintering process for zirconia ceramics can obtain dense ceramic sintered bodies at a lower temperature than pressureless sintering, and the sintering time is much shorter.

However, hot pressing sintering adopts unidirectional pressure, so the shape and size of the product are limited by the mold, which is generally cylindrical or annular.

In addition, unidirectional pressure also makes the pressure distribution in the green body uneven during hot pressing sintering, especially for samples with non-equiaxed crystal system. After hot pressing, the flaky or columnar grains are seriously oriented, which easily causes the anisotropy of the microstructure and mechanical properties of the ceramic sintered body.

In order to overcome these shortcomings of pressureless sintering and hot pressing sintering, it is urgent to develop a new sintering process.

- 1. The hot isostatic pressing sintering method combines the advantages of the hot pressing method and the pressureless sintering method. It can not only increase the density like hot pressing sintering, but also inhibit the grain growth and improve the product performance.It can also produce products with very complex shapes like the pressureless sintering method, and avoid the grain orientation of non-equiaxed samples.

- 2. The pressure of the current high temperature isostatic pressing device can reach 200MPa, and the temperature can reach 2000C or higher, because the gas is the pressure medium during hot isostatic pressing sintering.Since the pores in the ceramic powder or china are continuous, the sample must be encapsulated, otherwise the high pressure gas will penetrate into the sample and the sample cannot be densified.

- 3. Hot isostatic pressing can also be used to post-process the samples that have undergone pressureless sintering to further improve the density of the samples and clear harmful defects.

- Hot isostatic pressing has been successfully used in the sintering or post-machining of various structural ceramics, such as zirconia ceramics, alumina ceramics, etc.

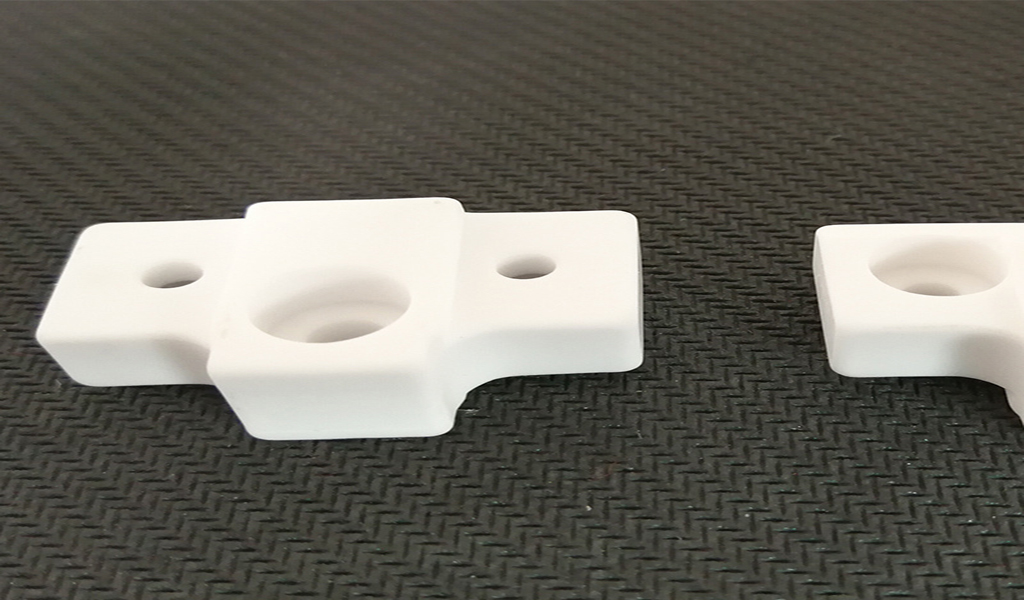

The above is what Pintejin Ceramics brings to you. Pintejin Ceramics is a manufacturer specializing in the production and machining of ceramics, focusing on the machining of alumina ceramic parts and zirconia ceramics, and can process ceramic products according to your needs.

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies