With the continuous development and progress of science and technology, Dongguan industrial ceramic products with superior performance have been widely recognized by the society. Do you have any precautions when using functional ceramic rods? The following is a professional manufacturer of zirconia ceramics, alumina ceramics and other functional ceramics to introduce the three points of attention for the use of industrial ceramic rods.

Precautions for the use of industrial zirconia ceramic rods Dongguan functional wear-resistant ceramic rods:

1. The surface temperature should not be too high.

Even very durable wear-resistant ceramic rods need to pay attention to the temperature of the use environment, because its life will be affected by the use of temperature. increasing and decreasing. When the temperature of the ceramic rod exceeds the upper limit of the furnace, its oxidation rate will be accelerated and its life will be shortened little by little, so users try to avoid making its surface temperature too high.

2. Timely adjustment of voltage

If the ceramic rod is oxidized during use, the resistance will gradually increase, so in order to keep the furnace temperature normal, the use voltage should be increased in time. If the voltage is increased to the maximum limit of the transformer used and still cannot meet the requirements, you can choose to stop the furnace and change the wiring method of the rod before continuing to use it. If the new furnace starts to send electricity, the voltage should be increased in time to avoid the occurrence of broken rods. The initial voltage should be half of the rated voltage, and then slowly increase after it is normal.

3. Avoid overload use

Even if the production process of ceramic rods is refined, the quality of the products produced cannot be overloaded. If the ceramic rod breaks or heats unevenly for some reason, and its part shows incandescent or dark red for a period of time, it means that the part of the rod has begun to age, and the resistance of the sections has been too different, The furnace should be stopped in time for maintenance and replacement of rods. The above are the precautions introduced by Pintejin ceramic manufacturers about the use of Dongguan functional ceramic products, hoping to help everyone.

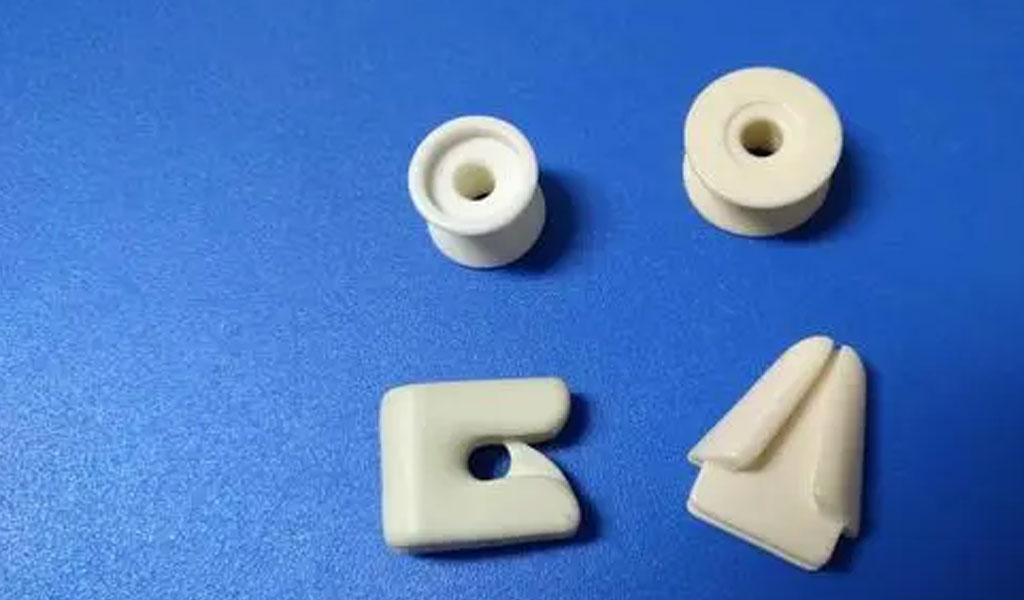

Pintejin Ceramics is a professional manufacturer of industrial ceramics, mainly engaged in the research and development and production of zirconia ceramics and alumina ceramics. We can process ceramic products according to your drawings, specializing in the production of high-precision ceramic rods, ceramic tubes, ceramic rings, ceramic plates, ceramic flanges, ceramic nozzles, and customized precision ceramic parts, etc.

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies