Alumina ceramic sheets are also known as wear-resistant alumina ceramic linings, high-alumina linings, wear-resistant ceramic linings, alumina ceramic patches. Alumina ceramic sheets are mainly made of al2o3 as raw materials and rare metal oxides as solvents. It is calcined at a high temperature of 1700 ° C. So how do we identify alumina ceramic sheets?

First of all, we have to look at the surface of the alumina ceramic sheet. The surface of a good alumina ceramic sheet is very smooth, without black spots on the surface, and the color is uniform. Secondly, we can identify the alumina ceramic sheet by measuring the density. Knowing the content of alumina, there is another way to identify the quality of alumina ceramic sheets by doing a wear test.

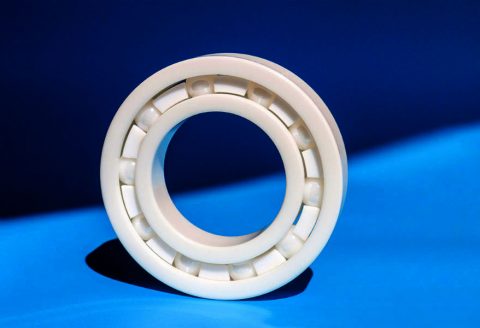

Any product has its front and back, and the alumina ceramic sheet also has its front and back. Next, I will briefly introduce the advantages and disadvantages of the alumina ceramic sheet: First, let’s talk about the advantages: the alumina ceramic sheet has high mechanical strength, wear resistance, resistance to Good corrosion resistance, good impact resistance, good thermal stability, abundant raw materials, low price, environmental protection and pollution-free products.

Let’s talk about the shortcomings of alumina ceramic sheets: the ability of post-processing is low, and the product is not suitable for recycling.