Ceramic micro-injection molding (μCIM) is a new technology developed on the basis of conventional CIM. After the information revolution, more and more micro-components (10-1000 μm) in the microelectronics industry use structural ceramic materials. Compared with ceramic parts prepared by traditional micromachining technology, there are high cost, low efficiency and difficult to unify size. shortcoming.

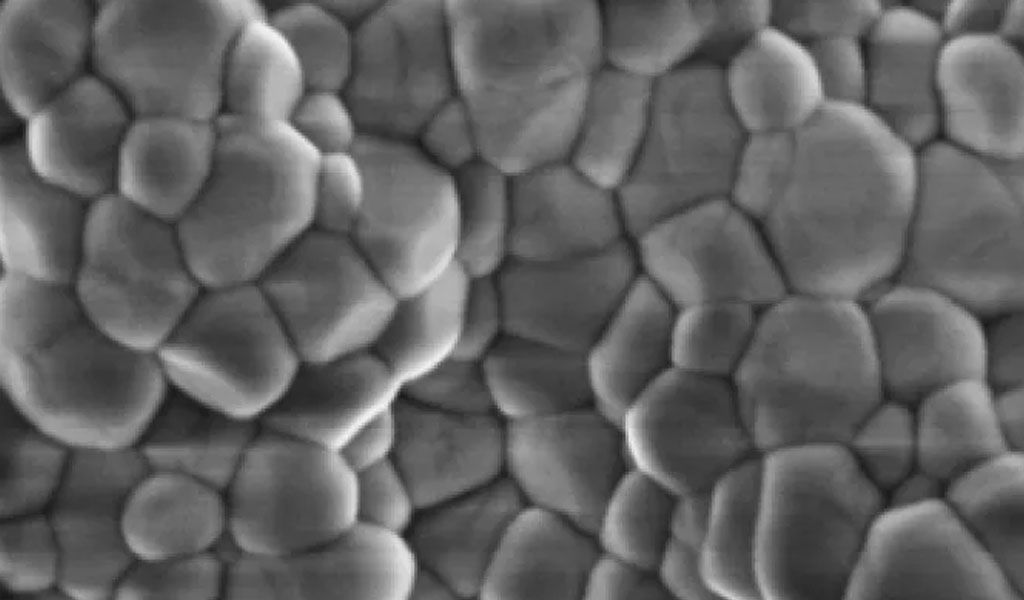

The ceramic micro-injection molding technology developed in recent years can obtain blanks of various shapes (including complex shapes) at one time, with high dimensional accuracy and uniform microstructure, and can realize automatic and large-scale production. A very promising advanced molding manufacturing technology [35-36]. The biggest difference between low pressure injection molding (LPM) and traditional injection molding is that the injection pressure is greatly reduced, and the molding pressure is generally 0.35-0.7 MPa.

The traditional ceramic injection molding pressure reaches 7-70 MPa, and paraffin or low molecular polymer is used to replace the traditional high molecular polymer in the process, which greatly reduces the viscosity of the slurry, so that it can be molded at low pressure and lower temperature [ 37]. Therefore, low-pressure injection molding has a series of advantages such as low cost, uniform green density, and high product dimensional accuracy.

However, based on paraffin or polymer binder systems, a separate debindering process is required, which takes a long time (usually tens of hours), and the binder system also suffers during the degreasing process. prone to defects

Pintejin machining ceramic service include : Alumina Ceramic Parts, Zirconia Ceramic, Silicon Carbide Ceramic, CNC Machined Aluminum Nitride Ceramic, Machinable Ceramic Parts, Glass Ceramic,Macor Ceramic,Powder Metallurgy Dies,Ceramic Injection Molding,Ceramic Dry Pressing,Ceramic Extrusion Dies