The sintering temperature of zirconia ceramics is very high when the recrystallized silicon carbide setter is used for production. high; The working temperature of the recrystallized silicon carbide setter plate can reach 1650 ℃; the thermal shock resistance is excellent and the best setter plate; but because the main component of the silicon carbide setter plate is SIC+SIO2; Among them, the SIO2 in the recrystallized silicon carbide setter plate cannot be completely obtained from the group, so some SIO2 still exists in the form of crystalline; Due to the relatively high activity of SIO2, when SIO2 encounters all substances that can be combined at high temperature, it will immediately combine Read more

Blog

To study the influence of porosity on thermal properties such as thermal conductivity of ceramic materials, it is necessary to prepare a series of samples. Porosity is the only main variable parameter in the product. This requires: the zirconia and alumina ceramic raw materials used between the samples are the same; the shape, size, orientation and other factors of the pores are roughly the same. It should be admitted that it is quite difficult to control the shape and size of the pores in the sample. Start from an angle, such as: Control the particle size of the added organic matter. Pass the organic matter (naphthalene powder) through two different Read more

Appearance of activated alumina: activated alumina is white spherical porous particles with uniform particle size, smooth surface, high mechanical strength, strong hygroscopicity, no swelling or cracking after water absorption, non-toxic, odorless, insoluble in water and ethanol, It has strong adsorption to fluorine and is mainly used for defluorination of drinking water in high fluoride areas. Activated alumina has selective adsorption capacity for gas, water vapor and moisture in some liquids. After the adsorption is saturated, it can be heated at about 175-315 ° C to remove water and resurrected. Adsorption and resurrection can be performed multiple times. In addition to being used as a desiccant, it can also absorb the Read more

95 alumina ceramic tube has excellent properties such as high temperature resistance, wear resistance and insulation, and is widely used in various industrial equipment and scientific research. Pintejin zirconia ceramic machining manufacturer will tell you the production and use of 95 alumina ceramic tube. 95 alumina ceramic tube powder is a high-performance ceramic tube manufactured by spray granulation, isostatic pressing and high temperature sintering process, 95 alumina ceramic tube. 95 alumina ceramic tube 95 alumina ceramic tube has the characteristics of high hardness, good wear resistance and corrosion resistance. It can be widely used as grinding media in ball mills, vibration mills, planetary mills and stirring mills. The 95 alumina Read more

Pintejin Ceramics is a professional ceramic manufacturer specializing in the production and machining of zirconia ceramics. It is a professional ceramic manufacturer integrating calcination, forming, machining and testing of zirconia ceramics. As a ceramic material with excellent performance, zirconia ceramics are widely used in various industries and are also important ceramic materials for future industrial and technological development. The following is an introduction to the development status and trends of zirconia ceramics by Pintejin Ceramics. Zirconia ceramic heating element Zirconia ceramic has excellent properties such as high temperature resistance, wear resistance, corrosion resistance, bending pressure resistance, good chemical stability, etc. It can be used to make ceramic valves, ceramic needle Read more

Alumina ceramics is a kind of high temperature structural ceramics with the most extensive uses, the most abundant raw materials and the lowest price. Alumina raw materials are abundant in source and low in price. According to the composition, it can be divided into two categories: alumina porcelain and high-alumina porcelain. Generally, the alumina content in alumina ceramics is more than 99%, and the sintering temperature is high. When the raw material particle size is coarse, the sintering temperature can reach 1700 ° C. In order to improve the sintering performance and reduce the sintering temperature, a small amount of MgO, Cr2 03, TiO2, etc. are often added as The Read more

Calcium oxide has a melting point of 2570°C, abundant resources and relatively cheap price, but it is difficult to sinter, has low stability in the atmosphere, and is easy to hydrate, which is the biggest problem in the manufacture of CaO products. The raw material used to prepare pure calcium oxide is chemically pure calcium carbonate or calcium hydroxide, which is burned at a temperature slightly higher than its decomposition temperature. In the process of manufacturing calcium oxide products, from the preparation of agglomerates to the firing of the products until they are used, they must be stored in a moisture-free medium. The hydration rate of calcium oxide in the Read more

Electrical ceramics have good corrosion resistance and high temperature resistance characteristics. They have a wide range of applications and really play an important role in actual use. So what are the classifications of electrical ceramics? Next, Pintejin ceramics will introduce to you. 1. Insulation device porcelain Device porcelain for short, has excellent electrical insulation properties, and is used as electronic ceramics for structural parts, substrates and casings in electronic equipment and devices. Porcelain parts of insulating devices include various insulators, coil bobbins, electronic tube sockets, band switches, capacitor strut brackets, integrated circuit substrates and packaging shells. 2. Capacitor porcelain Mainly used in the manufacture of ceramic capacitors for bypass, DC Read more

Alumina ceramics have excellent insulation, low high-frequency loss but good high-frequency insulation, so what are the properties that alumina ceramics will improve after machining? Next, Pintejin ceramics will introduce to you. 1. Improve hardness The Rockwell hardness is up to the standard. Taking the processed wear-resistant ceramic patch as an example, its hardness is second only to that of diamond. It was found after many experimental verifications by alumina ceramic manufacturers. Physically speaking, after the alumina wear-resistant ceramic patch is processed, its hardness far exceeds the wear resistance of stainless steel and wear-resistant steel. It can be seen that its hardness is significantly improved after machining. 2. The wear resistance Read more

Zirconia ceramic grinding method Zirconia ceramics have high structural strength at high temperature and have a negative temperature coefficient of resistance. Therefore, under certain circumstances, the material of the product needs to be ground to a certain extent. The specific methods are as follows: (1) Mechanical grinding of zirconia ceramics: When constructing zirconia ceramics on a large area, in order to improve work efficiency, mechanical grinding methods, such as electric grinders (disc type, vibration type), can be used. (2) Dry grinding of zirconia ceramics: use sandpaper for grinding. It is suitable for grinding hard and brittle paints. The disadvantage of grinding zirconia ceramic materials is that a lot of dust Read more

Ceramic Machining Industry

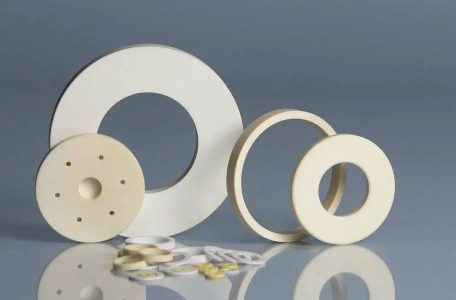

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump