Zirconia Ceramic Injection Molded Parts

The production and machining technology of special ceramics has been developing and changing continuously in recent decades. During the first 30 years, CIM was a small part of the vast ceramics industry, and the major advances in its commercial dynamism began mainly with the contribution of research and development in the 1970s and 1980s. In the 1980s, with the need for the development of ceramic engines and the preparation of complex-shaped ceramic heat engine components such as turbine rotors and blades, the American Betel Memorial Association organized nearly forty university research institutions and companies around the world to formulate ” “Ceramic Injection Molding” R&D program, injection molding provides a highly efficient manufacturing process for these parts. This process has continued to the present and has become a mature ceramic molding process – ceramic injection molding process.

At the beginning of this century, with the development of optical communication, the demand for zirconia ceramic ferrules and sleeves for optical fiber connectors, biomedical ceramic parts, electronic devices, precision machinery, ceramic watches and the recently developed ceramic appearance parts of mobile phones and smart wearable devices has further promoted Research and application of ceramic powder injection molding.

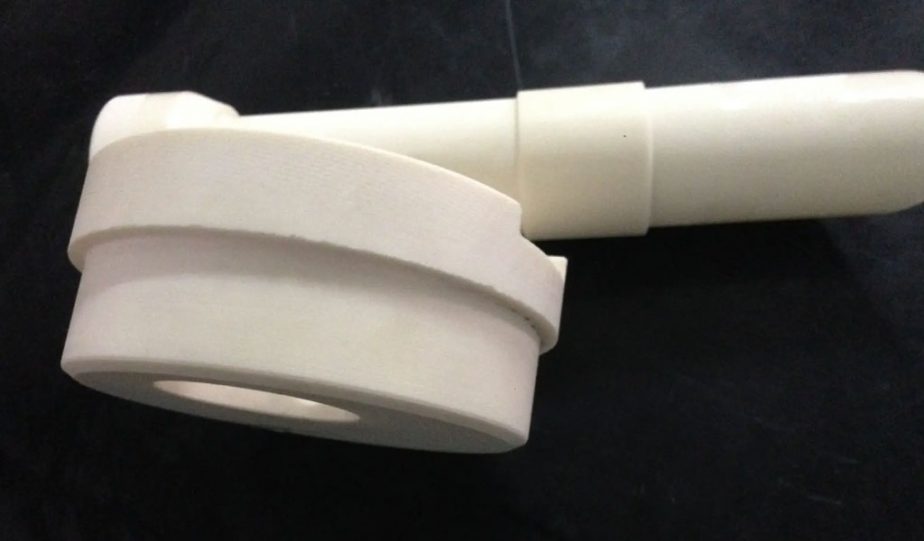

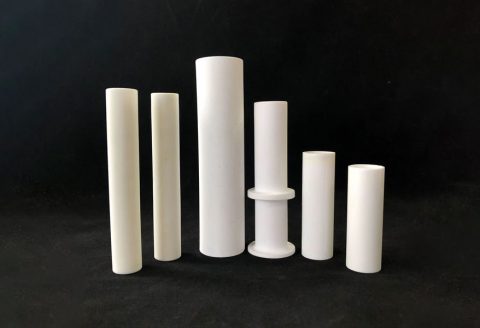

Ceramic injection molding is a common molding process in the production of special ceramics. Machiningceramic.com has a professional ceramic injection molding team that can provide users with precision injection molding of various ceramic materials. This product is a zirconia ceramic injection nozzle on the shampoo bottle. It has a smooth and jade-like texture and is very suitable for accessories of high-end products. Our ceramic injection molding parts include: oxide ceramic injection molding parts, alumina ceramic injection molding parts, silicon nitride ceramic injection molding parts, etc., which can fully meet the special requirements of different accessories. Welcome to call to discuss related business. Pintejin has a professional injection molding ceramic machining workshop and complete sets The equipment can provide users with a series of services from mold design to forming and sintering.

Categories: Zirconia Ceramic