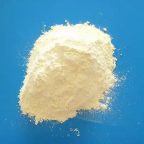

Zirconia Material

What Is Zirconia Ceramic Material

Zirconia material has excellent physical and chemical properties such as high hardness, high strength, high toughness, extremely high wear resistance and chemical corrosion resistance. Zirconia has been used in ceramics, refractory materials, machinery, electronics, optics, aerospace, biological , chemistry and other fields have been widely used.

The zirconia oxygen analyzer uses zirconia as the probe, which reacts with oxygen in the air to determine the oxygen content in the flue gas, and then sees whether the combustion is sufficient or not.

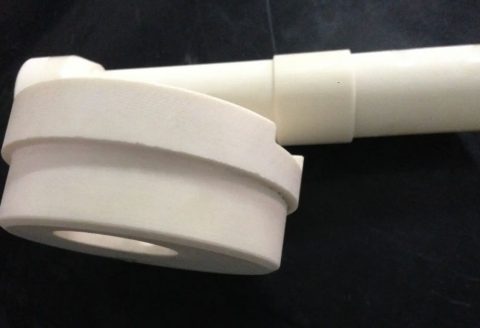

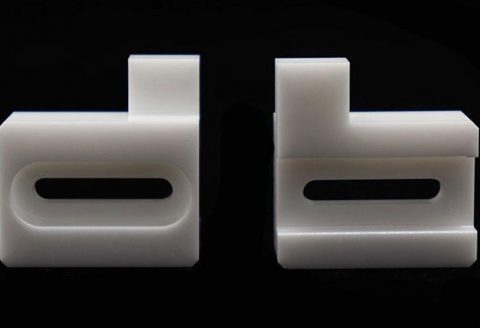

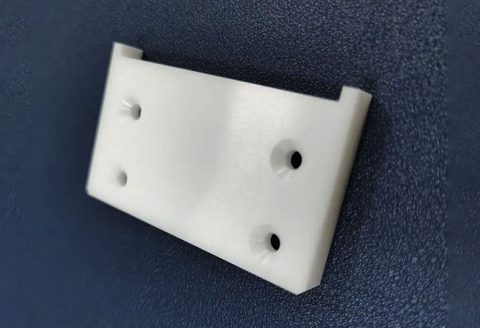

Zirconia Ceramic Parts Manufacturer In China

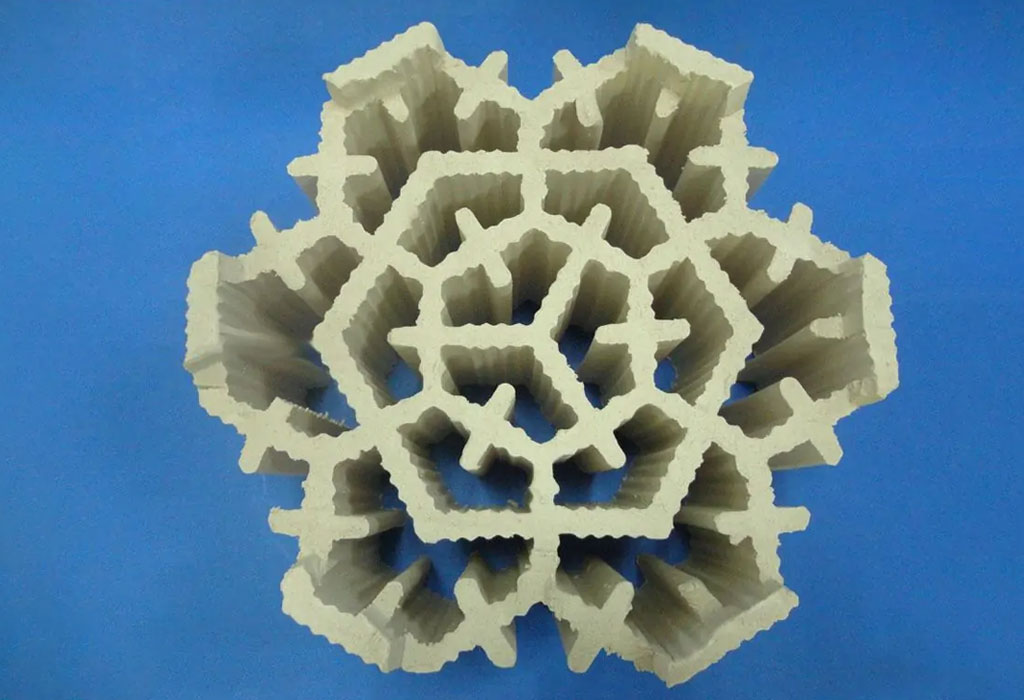

Pintejin ceramic machining shop focuses on the research and development and production of zirconia ceramic structural parts, and has supplied zirconia ceramic products to many domestic and foreign companies! Zirconia ceramics are a new type of advanced ceramics, mainly divided into three types of magnesium-stabilized zirconia ceramics, cerium-stabilized zirconia and yttrium-stabilized zirconia. All three kinds of zirconia ceramics have excellent physical and chemical properties. They have not only become research hotspots in the field of scientific research, but also have been widely used in industrial production. They are important raw materials for refractory materials, high-temperature structural materials and electronic materials. Among various metal oxide ceramic materials, zirconia has high temperature thermal stability, good thermal insulation performance and strong toughness, and is suitable for ceramic thermal insulation sleeves and high temperature refractory products. Zirconium-based ceramic pigments with zirconia ceramics as the main raw material are important components of glazes; the thermal conductivity of zirconia is low among common ceramic materials, and the thermal expansion coefficient is close to that of metal materials, making it an important structure. Ceramic materials; the same special crystal structure of zirconia ceramics makes it an important electronic material;

The molding of zirconia ceramics includes dry pressing molding, isostatic pressing molding, injection molding, grouting molding, hot die casting molding, tape casting, plastic extrusion molding, colloidal solidification molding, etc. Among them, isostatic pressing, injection molding and dry pressing are widely used.

The List Of Zirconia Material

The Technical Parameters Of Zirconia Ceramic Material

|

project

|

unit

|

Zirconia

|

|

density

|

g / cm3

|

6.05

|

|

water absorption

|

%

|

0

|

|

Thermal expansion coefficient

|

10-6 /k

|

10.5

|

|

Young’s modulus of elasticity

|

Gpa

|

210

|

|

Poisson’s ratio

|

/

|

0.3

|

|

Hardness (HV)

|

MPa

|

1200

|

|

Flexural strength (room temperature)

|

MPa

|

950

|

|

Bending Strength (700℃)

|

MPa

|

210

|

|

Compressive strength (room temperature)

|

MPa

|

2000

|

|

fracture toughness

|

Mpa.m1/2

|

10

|

|

Thermal conductivity (room temperature)

|

W/m.k

|

2

|

|

Specific resistivity (room temperature)

|

Ω.mm2/m

|

>1015

|

|

Operating temperature

|

℃

|

≤1350

|

|

Acid and alkali corrosion resistance

|

/

|

powerful

|