The feeder is used in: Glass production.

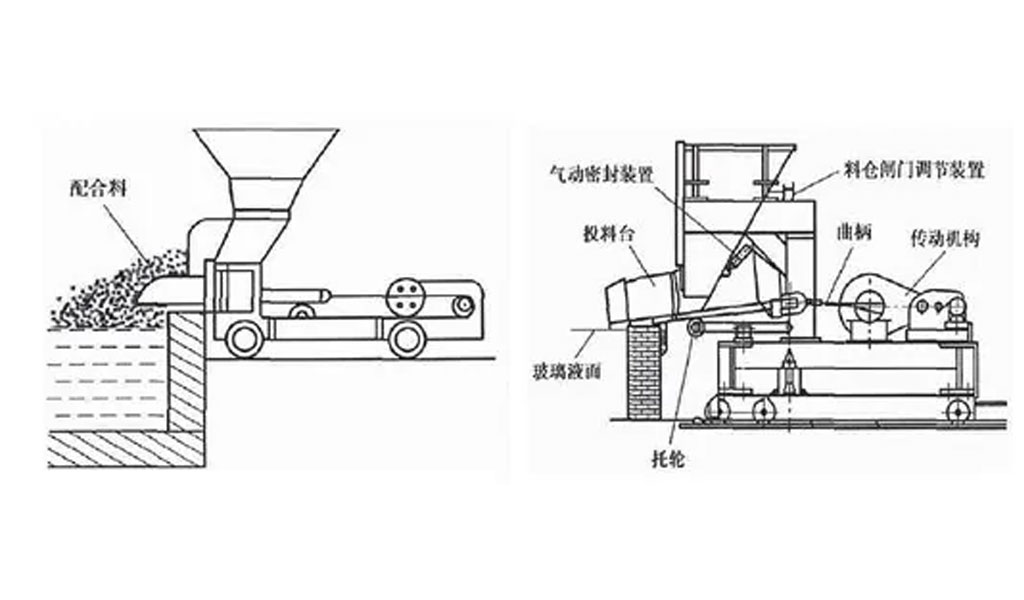

During glass production and process, the proportion of raw materials is prepared and melted in the kiln; the glass breaking liquid flows into the forming equipment to form a flat glass prototype, which is sent to the cold end through edge drawing and annealing, and is longitudinally cut, edge trimmed, cross-cut, It is completed by the process of edge breaking, vertical breaking, vertical splitting, slicing, inspection, stacking and packing. Feeding the raw materials into the melting furnace is the first step in the whole process, because the raw materials are sent to the Shang-temperature melting furnace with a temperature of more than 1,000 degrees. People can’t get close at all: the second is that the thickness of the feeding layer and the feeding speed must be uniform, and the work cannot be completed by manpower; this requires a special equipment to complete this task – a feeding machine. This not only saves manpower but also enables very precise and even feeding by adjusting the motion parameters of the feeder. When the glass specification needs to be changed, as long as the motion parameters of the feeding machine are changed, the corresponding feeding amount can be accurately determined, and the operation is convenient, so it is widely used in glass production.

The feeder is used in: ceramic production.

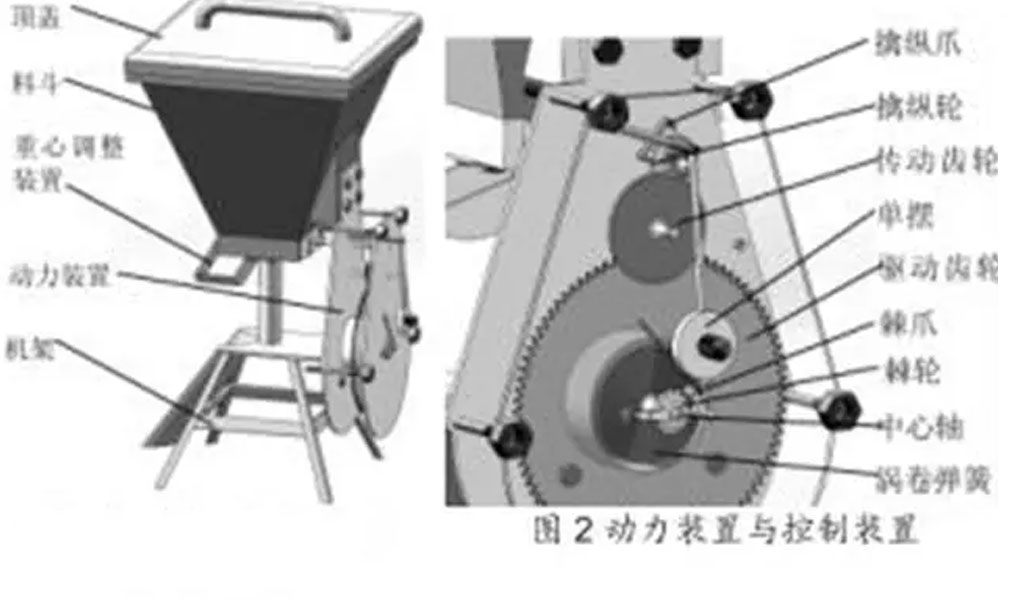

At present, most of the ceramic daily necessities, such as bowls and cups, are produced in large quantities and semi-mechanized by rolling forming machines. However, the feeding of the roll forming machine is mostly manual operation, which not only has high labor intensity, but also has low quality of finished products, low yield of green body and high production cost. To produce a ceramic dish with relatively small deformation, it is first required that the semi-finished product has a symmetrical uniform and small shrinkage suitable for its shape. To achieve this, it is required that the mud cake is placed in the center at the beginning of molding, and the upper and lower planes of the mud cake are correctly oriented and the size of the mud cake is appropriate. The manual feeding method requires the feeding workers to put the mud cake nervously with the rhythm of the machine, and must deal with the mud section joints at any time. The work intensity is high, and the accuracy of feeding the mud cake is relatively low, and the upper and lower planes of the mud cake cannot be considered. Orientation, so the deformation of the porcelain body is large, and the deformation is not uniform, so the yield is also low. Therefore, the feeder is also an indispensable small mechanical equipment in ceramic production.

The feeder is used in: metallurgical steelmaking.

In the steelmaking production in the metallurgical industry, the auxiliary raw material silo in the converter is generally designed according to the demand for the steel type and various auxiliary raw materials required. The basic arrangement is a material silo with a large amount of use and a large volume, and some are set as two silos, such as lime silo. However, some material silos with a small amount have a small capacity, and in the production process, it is necessary to rely on the feeder to input the corresponding materials at the right time. In order to speed up the production rhythm, improve the level of steelmaking, save energy and reduce consumption; at the same time, in order to reduce manual errors, various steel mills are increasingly using automatic feeders.