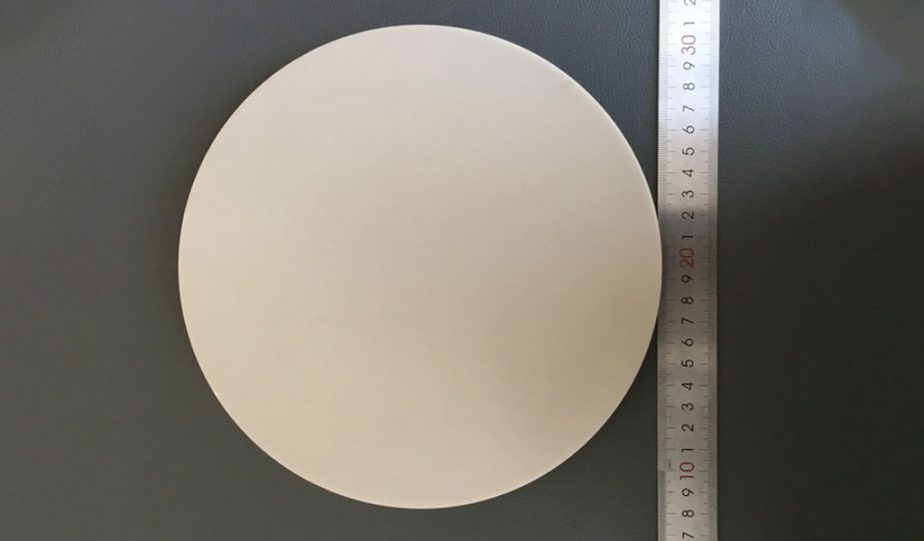

ALN Aluminum Nitride Ceramic Heating Plate

Pintejin makes Aluminum Nitride (AIN) into common forms and finely machined parts for a variety of precision electronics applications, especially the semiconductor industry, and we supply high-quality Aluminum Nitride ceramic parts for chip manufacturing.

Aluminum nitride is a versatile material most commonly used in scenarios where high thermal conductivity and electrical insulation are required. This unique ability, combined with its low toxicity, makes AIN ideal for rapid heating and cooling of other components and systems such as radiators and heat sinks. For example, the aluminum nitride ceramic processing hot plate (heater), aluminum nitride ceramic wafer tray, etc. produced by Pintejin.

In addition, its low coefficient of thermal expansion similar to that of silicon means that AIN is a reliable substance for semiconductor products. The material remains highly stable over a wide temperature range.

In high-power electronic applications, components such as solid-state transistors generate large amounts of heat, which can affect performance. Substrates made of AIN can remove heat while acting as an insulator for mounting components. Likewise, LED applications generate a lot of heat. Traditional heat sinks work with AIN substrates to dissipate heat and improve performance.

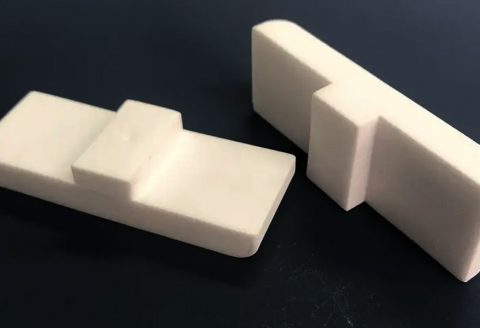

Pintejin has extensive experience in the processing of aluminum nitride ceramic heaters to manufacture blocks, plates and bars. We have the practical knowledge needed to machine AIN into fine rings and other custom parts to exacting tolerances and specifications. Our sophisticated machining techniques allow Pintejin to drill, grind or thread aluminum nitride with extreme precision and repeatability.

Categories: Aluminum Nitride Ceramics, Semiconductor Ceramics