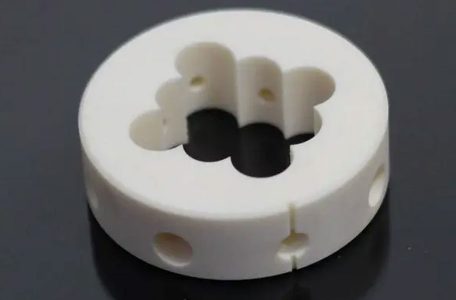

Industrial ceramic mechanical parts are widely used in various industries now, and their excellent performance makes them replace traditional materials. The following Pintejin zirconia ceramic machining manufacturers will tell you about the performance and main uses of industrial ceramic mechanical parts. As an inorganic non-metallic material, special ceramic materials for industrial ceramics and mechanical parts have many properties that metal materials do not have, such as: high strength, high hardness, high elastic modulus, high temperature resistance, wear resistance, corrosion resistance, oxidation resistance , Thermal shock resistance. In addition, the current ceramic molding process is also mature, ceramic materials can be made into various non-standard shapes of industrial ceramic mechanical parts Read more

Blog

How can wear-resistant ceramics save costs better? Pintejin ceramics manufacturer is a manufacturer specializing in the production of wear-resistant ceramics such as zirconia ceramics and alumina ceramics. Next, Pintejin ceramics manufacturers will introduce to you how wear-resistant ceramics can better save costs. Wear-resistant alumina ceramic tube Wear-resistant ceramics When choosing wear-resistant ceramics as the lining plate of blast furnace top protection charging equipment, it is necessary to select wear-resistant ceramic materials with different properties according to the special operating conditions of blast furnace top charging equipment. However, wear-resistant ceramic is a new type of wear-resistant material. Since it is a non-metallic material, it is connected and fixed to the metal Read more

Ceramic materials have been an integral part of various industrial applications due to their unique properties, such as high hardness, thermal resistance, and chemical stability. One area where ceramics are being explored is in the manufacturing of spinning molds. Metal Spinning molds, essential in the production of spinning components for various industries, require materials that can withstand significant stresses and high temperatures. This article explores the potential and practicality of using ceramic materials for spinning molds, examining their properties, advantages, challenges, and current research in the field. 1. Background on Spinning Molds Spinning molds are utilized in processes such as centrifugal casting and spinning casting, where materials are spun at Read more

Zirconia ceramic properties There are two main types of zirconium-containing ores in nature: baddeleyite (zirconia) and zircon (zirconia-SiO:). Zirconia is extracted from zirconium-containing ore. The purer zirconia powder is yellow or gray. High-purity zirconia powder is white. However, it often contains hafnium dioxide impurities. The chemical properties of the two are similar and they are not easy to separate. They also have similar effects on the electrical properties of the material. The density of zirconia is 5.49 gcm3 and the melting point is 2715°C. Crystalline morphology and crystal form transformation of zirconia Zr0 at different temperatures. It exists in three forms of allom orphish, namely cubic system, monoclinic system and Read more

Ceramic materials are recognized as one of the most dynamic new materials in the 21st century due to their excellent wear resistance, corrosion resistance, high temperature resistance, low density and other properties. Next, Pintejin Ceramics will introduce the classification of ceramic materials and its Definition. By summarizing the characteristics and application fields of various ceramics, a new prospect is made for the future development of ceramic materials, and the application direction and development trend of ceramic materials are revealed. Functional ceramics refer to materials that mainly utilize their non-mechanical properties during application. Such materials usually have one or more functions, such as electrical, magnetic, optical, thermal, chemical, biological and other Read more

Zirconia structure ceramic monoclinic ZrO2→tetragonal ZrO2→cubic ZrO2→melt 1170℃, 2370℃, 2715℃ natural ZrO2 and ZrO2 obtained by chemical method belong to the monoclinic crystal system. The transition between the monoclinic and tetragonal forms is accompanied by a volume change of around 7%. When heated, it is transformed from monoclinic ZrO2 to tetragonal ZrO2, and the volume shrinks, and when cooled, it is transformed from tetragonal ZrO2 to monoclinic ZrO2, and its volume expands. But this shrinkage and expansion do not occur at the same temperature, the former is about 1200°C and the latter is about 1000°C. Due to the volume change caused by the transformation of the crystal form, it will Read more

The precision ceramic parts we are familiar with include zirconia ceramics, alumina ceramics and other industrial ceramic parts used in various fields. With the progress of the times, the field of application of precision ceramic parts is also expanding. Ceramic machining manufacturers are also increasing day by day. Faced with so many ceramic machining manufacturers, how should they make better choices? The following is a key introduction to the professional ceramic machining manufacturer Pintejin ceramic manufacturer. Alumina ceramic tube The following three points are used to explain how to choose a reliable ceramic machining manufacturer. First, select a powerful ceramic machining manufacturer to purchase products based on demand. Different companies Read more

Alumina ceramic rods have wear resistance and long service life; smooth surface, low frictional resistance, low bulk density, light weight, can resist erosion of various acids, alkalis and salts, and their strength is second only to diamond. So what should we pay attention to when accepting alumina ceramic rods? Next, Pintejin Ceramics will introduce to you. Alumina ceramic products are used in many aspects of industrial production. Among them, alumina ceramic rods are very popular. Because of the market demand, there are more and more enterprises producing alumina ceramic products. Points to pay attention to when accepting alumina ceramic rods 1. Many alumina ceramic products used in industrial production have Read more

The main function of alumina ceramic ring is to provide a growth and breeding environment for nitrifying bacteria, thereby improving water quality. So what are the advantages and disadvantages of alumina ceramic ring? Next, Pintejin Ceramics will introduce to you. Alumina ceramics have low dielectric constant, low dielectric loss, high dielectric strength, high volume resistivity, good flexural strength, high stability, high compressive strength, and good thermal shock resistance. It is widely used in thermostats, insulating parts, various thermal equipment, electric and electrical equipment, iron-structured buildings, shipbuilding, etc. of various small household appliances. The advantages of alumina ceramic ring are high hardness, excellent wear resistance, corrosion resistance and high temperature resistance, Read more

As a manufacturer of zirconia ceramic shafts, Pintejin Ceramics Factory can customize and process various types of ceramic shafts according to the drawings, and the ceramic machining accuracy can reach 0.001mm. Below, Pintejin Ceramics Factory will briefly introduce the zirconia ceramic shafts to you. Zirconia ceramic shaft standard parts refer to the commonly used ceramic shafts that have been completely standardized in structure, size, drawing, marking and other aspects, and are produced by professional factories. They have light structure, good electrical insulation performance, small thermal expansion coefficient, no Magnetically conductive, non-conductive, high speed, low noise, high temperature resistance, wear resistance, acid, alkali, salt corrosion, non-toxic, dimensional stability under high temperature Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump