In the field of precision machining, particularly for CNC (Computer Numerical Control) machining of non-circular parts, achieving high accuracy and productivity under various disturbance conditions is a critical challenge. Non-circular parts, such as ellipses, polygons, and irregular curves, present significant difficulties in maintaining the desired geometric integrity during the machining process due to inherent non-linearities, varying cutting conditions, and external disturbances. CNC machines are designed to execute precise motions and operations based on pre-programmed instructions, often with real-time feedback control mechanisms. However, these systems face significant challenges in adapting to disturbances that may arise during machining. These disturbances could be caused by tool wear, varying material properties, dynamic forces, thermal Read more

Blog

Wear-resistant zirconia ceramic cutters manufacturers claim that zirconia ceramic cutters are ceramic inserts for high-tech cutting. Do you know the advantages of zirconia ceramic cutters? The following is an explanation of the advantages of zirconia ceramic cutters by Pintejin ceramic manufacturers. The advantages of zirconia ceramic cutter: 1. Corrosion resistance, extremely high corrosion resistance 2. Made of corrosion-resistant ceramics, suitable for corrosive cutting materials 3. Anti-static, no static load 4. Service life Longer, the service life is up to 6 times that of ordinary steel knives 5. Very wear-resistant, low friction coefficient, clean cutting edge The advantages of ceramic cutters, and then introduce the preparation of zirconia ceramic knives: 1. Read more

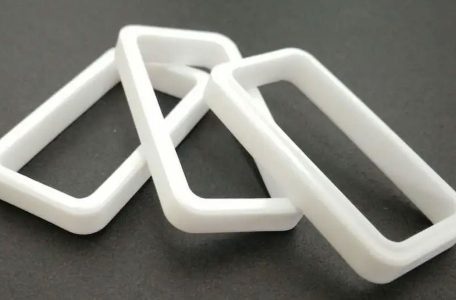

Sheet forming also belongs to plastic forming. The prepared billet is mixed with a certain amount of organic plasticizer to make it plastic. Plasticizers are prepared from adhesives, plasticizers, solvents, defoamers, etc. Adhesives are required to have sufficient adhesive force, good film-forming properties (good ductility and toughness), and have the characteristics of less ash after burning and non-toxicity. The role of the plasticizer is to insert between the segments of the polymer compound, weaken the attraction between each other, and prevent the adhesive from elastic shrinkage and rupture after being deformed by force, thereby improving the plasticity of the blank. The main function of the solvent is to dissolve the Read more

For ceramic knives, how much do you know about ceramic knives in addition to their performance? Next, Pintejin Ceramics Factory, a professional manufacturer of zirconia ceramics and alumina ceramics, will introduce the information about ceramic knife products to you. Zirconia ceramic cutting knife Zirconia material has excellent physical and chemical properties such as high hardness, high strength, high toughness, extremely high wear resistance and chemical corrosion resistance. Zirconia has been used in ceramics. Product Details: Is the ceramic knife made of ceramics? Are ceramic knives easy to use? The first brand of ceramic knives, Pintejin Ceramics Factory, tells you the secrets of ceramic knives and gives you a clear understanding Read more

With the advancement of modern technology, ceramic nozzles are more and more widely used, and they have been continuously improved and updated. The following is introduced by Pintejin Ceramics. Zirconia ceramic machining nozzles We refer to the following types of ceramic nozzles in China: 1. Oxide ceramic nozzles (referring to alumina and zirconia materials) 2. Nitride ceramic nozzles (referring to silicon nitride combined with silicon carbide materials) 3. Silicon carbide ceramic nozzles (referring to silicon carbide, boron carbide materials) However, because the performance of oxide ceramic nozzles is not as good as that of silicon nitride nozzles and silicon carbide nozzles, they have been gradually eliminated. Ceramic nozzles are wear-resistant Read more

Classification of advanced functional ceramics: (l) Piezoelectric ceramics Piezoelectric ceramics refers to a functional ceramics with piezoelectric effect, which is one of piezoelectric materials. The so-called piezoelectric effect refers to the phenomenon that the polarization (or electric field) is induced by stress, or the stress (or strain) is induced by the electric field. The former is a positive piezoelectric effect, and the latter is a negative piezoelectric effect. Electric effect. Piezoelectric ceramics is a kind of polycrystal. According to the crystal structure, there are perovskite type, tungsten bronze type, pyrochlore type, etc. Currently, perovskite type is widely used, such as barium titanate, lead titanate, zirconium titanium Lead acid, etc.Mainly used Read more

The properties of zirconia ceramic powder are very important to the quality of the advanced ceramics. The “quality” here not only refers to the excellent performance and repeatability of the product, but also includes the excellent process performance and stability. In order to achieve this ideal state. Advanced ceramic powder should have the following characteristics. (1) Precise chemical composition Accurate chemical composition is a basic requirement, because for advanced ceramics. Different chemical compositions directly determine the phase and phase of the produced crystals. Bianeng, if the chemical composition deviates, the result will be unrecognizable. Such as PZT piezoelectric ceramics. When Zr:Ti=52:48, it is the phase boundary between the trigonal phase Read more

Zirconia ceramic materials can be processed to produce industrial ceramic parts, such as zirconia ceramic cutters. This kind of ceramic parts can play a great role in industrial equipment. Today, Pintejin Ceramics Factory will introduce the advantages of this ceramic to you. What is the relationship between zirconia ceramics and metal materials? Due to the use of zirconia ceramics, many products have been made, such as zirconia ceramic cutting knives, power circuits, instrument panels, smart transmitters and many other products. What is the relationship between this product and metal materials? This product is all made from the basic principles of metal materials, using the properties of zirconia ceramics. Therefore, zirconia Read more

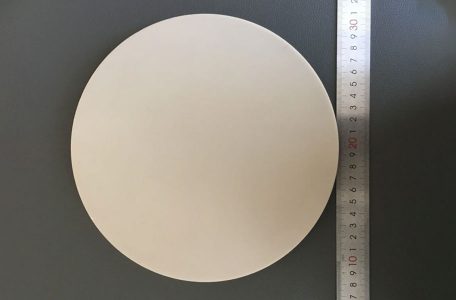

Structural ceramics refer to ceramics used in various industrial sectors to manufacture mechanical equipment and machining tools. Functional ceramics are a kind of spiritual material. So what are the industrial applications of structural ceramics? Next, Pintejin ceramics will introduce to you a bit. Structural, also known as engineering ceramics, precision ceramics, has superior wear resistance and corrosion resistance compared with traditional structural ceramics. Structural ceramics are known oxide ceramics with the best comprehensive properties of strength and toughness due to their phase transformation toughening properties. Widely used in injection molding ceramic parts, dispensing ceramic accessories, ceramic sleeves, ceramic seals, medical food ceramics, electronic and electrical ceramics, mining equipment and other Read more

The zirconia ceramic knife is made of zirconia ceramics. The ceramic blade is a new type of blade made of high-tech nanomaterial technology. So what safety precautions should be paid attention to when using the zirconia ceramic knife? Next, Pintejin Ceramics will introduce to you. When using zirconia ceramic knives, pay attention to the following points, which will minimize the unsafe problem of using zirconia ceramic knives. 1. Do not twist the blade during cutting, as this may easily deform or break the blade. 2. Do not use ceramic knives to cut frozen or not completely frozen food or items. 3. Do not wash ceramic knives in the dishwasher. You Read more

Ceramic Machining Industry

- Ceramic Flange

- Ceramic Nozzle

- Ceramic Pin

- Ceramic Plunger

- Ceramic Rod

- Ceramic Shaft/Ceramic Sleeve

- Ceramic Structure Parts

- Ceramic Valve

- Ceramics Cutter

- Electronic Ceramics

- Medical Food Ceramics

- Petrochemical Ceramics

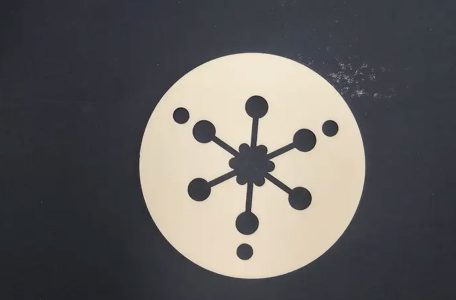

- Photovoltaic Ceramic

- Semiconductor Ceramics

- Microporous Ceramic Suction Cup

- Lithium Battery Ceramic Pump