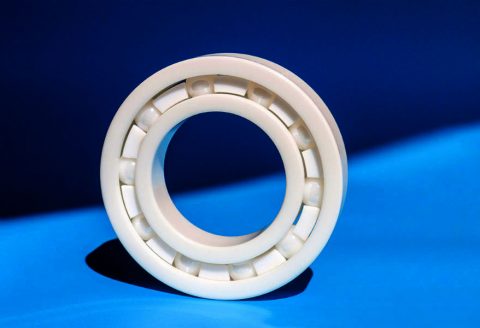

Ceramic Plane Machining

The hardness of zirconia ceramics and alumina ceramics is second only to that of diamond, so the ceramic plane is generally machined by a surface grinder. After the ceramic plane is machined by the surface grinder, the cnc machining accuracy can reach up to 0.003mm. Pintejin ceramic machining shop has 17 surface grinding machines, which can produce products that customers have high precision requirements for flat surfaces. Similarly, we can process all kinds of non-standard ceramic structural parts and special-purpose ceramic accessories according to the customer’s use environment, drawing requirements and material properties! The main materials include: alumina ceramics, zirconia ceramics.Provide drawings (format: CAD, PDF, JPG, step, etc.) or samples. Information includes: quantity, material, precision tolerance, surface treatment and special requirements.

Our company can modify or design the drawings appropriately according to customer needs. You can directly send the drawings to [email protected] and notify by phone or information.

The precision we can achieve in ceramic machining:

| The Dimensional Accuracy Of Plane Machining(In Pintejin) | Ceramic Plane Machining Can Reach 0.001mm(In Pintejin) |

|---|---|

| Degree Of Finishing | Reachable Mirror |

| Concentricity | Ceramic Plane Machining up to 0.003mm |

| parallelism | Ceramic Plane Machining Can reach 0.002mm |

| Bore Tolerance | Machinable 0.005mm |

| straight groove | Can be machined to a groove width of 0.1×100mm |

| Thickness dimension | Can be processed to 0.3mm |

| Thread | Machinable internal thread M2, external thread is not limited |

| Cylindricity | Can reach 0.004mm |

| Linear tolerance | Can reach 0.001mm |

| Minimum aperture | Machinable 0.5mm (open mold 0.1mm) |

We take care of all of your ceramic machining and parts fabricating needs!